Parameterization designing system for non-standard parts of hydraulic cylinders and method thereof

A parametric design, non-standard parts technology, applied in computing, electrical digital data processing, special data processing applications, etc., can solve the time-consuming and laborious management of repetitive production and classification of engineering drawings, lack of design basis, and difficult to control assembly constraints, etc. problems, to avoid duplication of production, design accurate and efficient, reduce time and space costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific implementation methods.

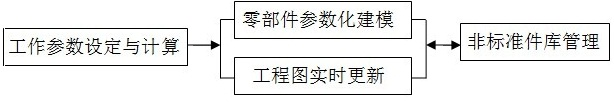

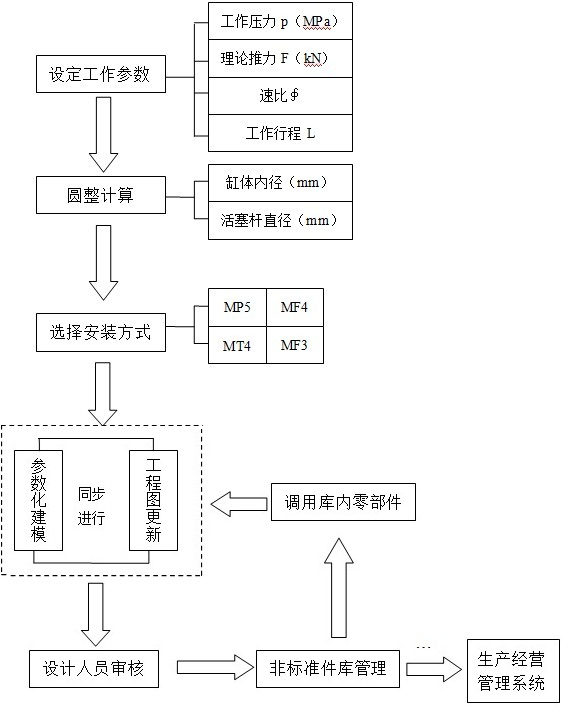

[0028] Such as figure 1 and figure 2 As shown, a parametric design system for hydraulic cylinder non-standard parts, including:

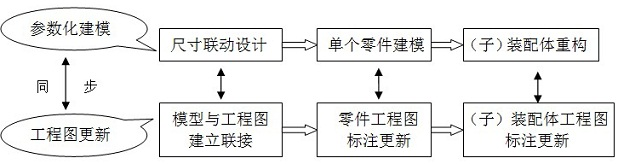

[0029] The working parameter setting and calculation module of the hydraulic cylinder is used to determine the initial conditions of the parametric design of the hydraulic cylinder and perform rounding calculations on the basic dimensions; the component parameterized modeling module is used to assign the parameter values calculated by the mathematical model to each Parts correspond to the dimensions, model and save the parts, and finally complete the reconstruction of sub-assemblies and assemblies, and create hydraulic cylinders that meet the design requirements; the real-time update module of engineering drawings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com