Preparation method of gas sample in vinyl gas chromatography analysis of 110 methylvinyl silicone rubber

A methyl vinyl silicon, gas chromatography technology, applied in the direction of analysis of materials, material separation, instruments, etc., can solve problems such as large errors and poor operation of gas sample preparation, achieving small errors, short testing time, and time-consuming short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

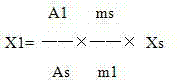

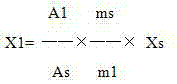

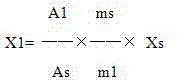

Image

Examples

Embodiment 1

[0031] The preparation method of gas sample in 110 methyl vinyl silicone rubber vinyl gas chromatography analysis, the steps are as follows:

[0032] a. Sample handling:

[0033] Weigh 0.0190g of the sample into the bottom of a dry and clean headspace sample bottle, add 0.1g of potassium hydroxide, and then use a capper to press the matching cap on the headspace sample bottle to seal it, and place the sample bottle at 200°C Keep the temperature in an electric drying oven for 10 minutes to completely crack the sample, and collect the generated ethylene gas in a sample bottle. `

[0034] b. Processing of standard samples

[0035] Weigh 0.0190g of a standard sample of methyl vinyl silicone rubber with known vinyl content into the bottom of a dry and clean headspace vial, add 0.1g of potassium hydroxide, and press the matching cap on the headspace with a capper Seal the sample bottle, put the standard sample bottle in an electric drying oven at 200°C for 10 minutes at a constan...

Embodiment 2

[0056] The preparation method of gas sample in 110 methyl vinyl silicone rubber vinyl gas chromatography analysis, the steps are as follows:

[0057] a. Sample handling:

[0058] Weigh 0.0200g of the sample into the bottom of a dry and clean headspace sample bottle, add about 0.1g of potassium hydroxide, then use a capper to press the matching cap on the headspace sample bottle to seal it, and put the sample bottle into 200 ℃ in an electric heating oven for 10 minutes to completely crack the sample, and collect the generated ethylene gas in a sample bottle. `

[0059] b. Processing of standard samples

[0060] Weigh 0.0200g of a standard sample of methyl vinyl silicone rubber with known vinyl content into the bottom of a dry and clean headspace sample bottle, add about 0.1g of potassium hydroxide, and then press the matching cap on the top with a capper. Seal the empty sample bottle, place the standard sample bottle in an electric drying oven at 200°C for 10 minutes at a co...

Embodiment 3

[0081] The preparation method of gas sample in 110 methyl vinyl silicone rubber vinyl gas chromatography analysis, the steps are as follows:

[0082] a. Sample handling:

[0083] Weigh 0.0210g of the sample into the bottom of a dry and clean headspace sample bottle, add 0.1g of potassium hydroxide, then use a capper to press the matching cap on the headspace sample bottle to seal, and place the sample bottle at 200°C Keep the temperature in an electric drying oven for 10 minutes to completely crack the sample, and collect the generated ethylene gas in a sample bottle. `

[0084] b. Processing of standard samples

[0085] Weigh 0.0210g of a standard sample of methyl vinyl silicone rubber with known vinyl content into the bottom of a dry and clean headspace sample bottle, add 0.1g of potassium hydroxide, and then press the matching cap on the headspace with a capper Seal the sample bottle, put the standard sample bottle in an electric drying oven at 200°C for 10 minutes at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com