Dynamic pre-tightening force measurement method of main shaft bearing of machine tool

A technology of machine tool spindle and measurement method, which is applied in the direction of mechanical bearing testing, force/torque/work measuring instrument, measuring device, etc. Accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

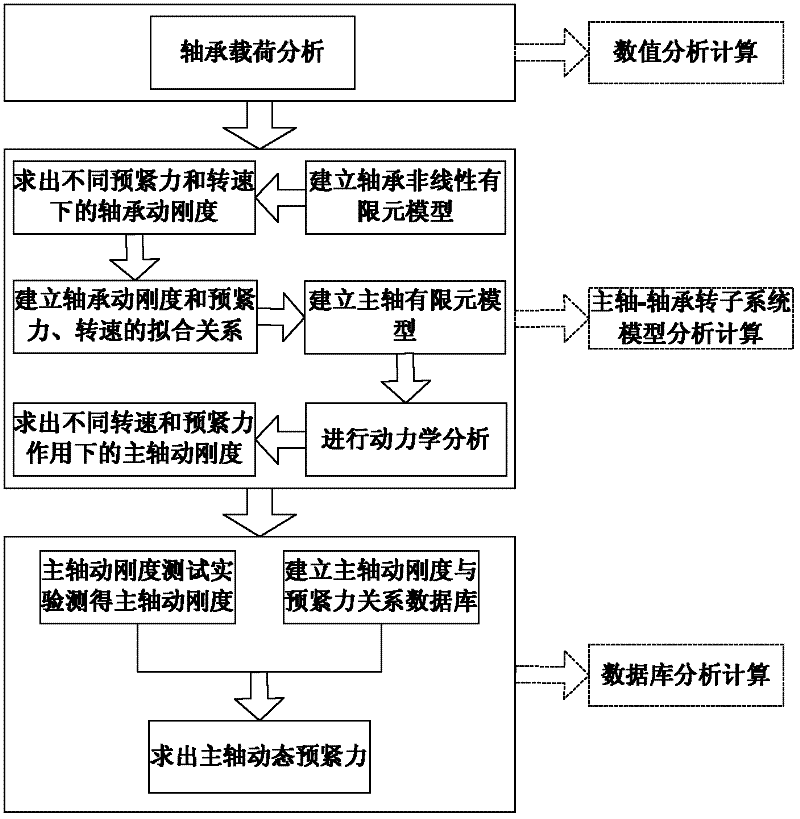

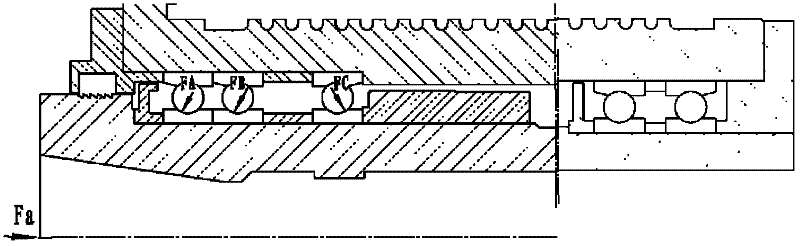

[0013] Attached below Figure 1 to Figure 4 The method for measuring the dynamic preload force of the main shaft bearing of the machine tool of the present invention is introduced in detail:

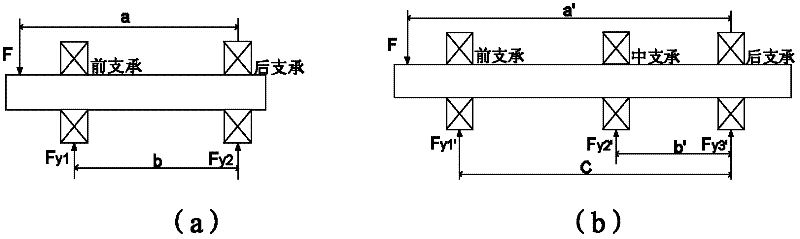

[0014] 1. Establish a mechanical model of the main shaft. According to the actual structure of the main shaft, it can be divided into a two-bearing support-rotor system and a three-bearing support-rotor system, such as figure 2 As shown, according to the force and moment balance equation, the force of each bearing is calculated by numerical calculation method. for figure 2 For the two bearing support-rotor system shown in (a), the bearing support reaction force can be obtained according to the force and moment balance equation:

[0015] F - F y 1 - F y ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com