An overhead conductor galloping test device and test method based on gear end displacement excitation

A technology of overhead wires and test devices, which is applied in the direction of measuring devices, vibration tests, and machine/structural component tests, and can solve problems such as the inability to conduct galloping mechanism research and the simulation of conductor galloping mechanisms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

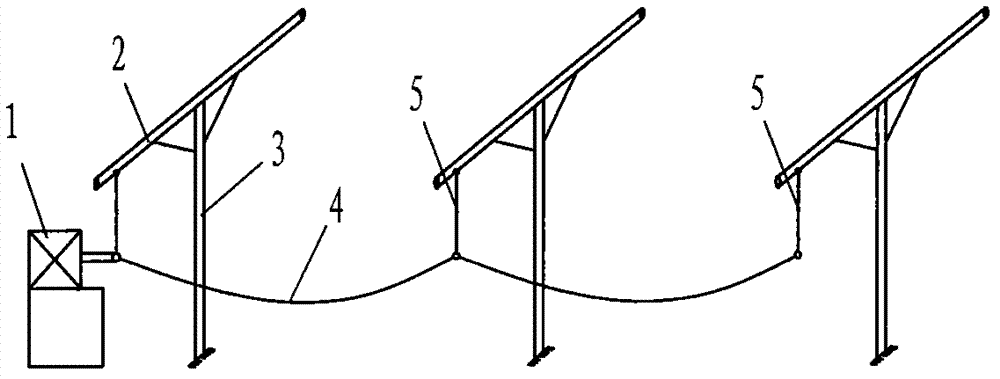

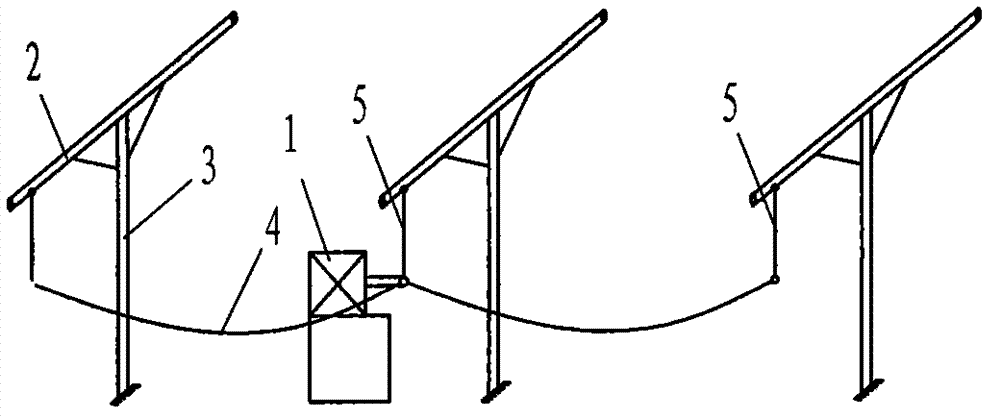

[0028] According to attached figure 1 It can be seen that the present invention specifically relates to an overhead wire galloping test device based on gear end displacement excitation, including a wire hanging device, a lateral drive device 1, an overhead wire 4 and an insulator string 5, the wire hanging device is fixed on the ground, and the two ends of the overhead wire 4 The insulator strings 5 are respectively connected to the two wire-hanging devices, and the lateral drive device 1 is connected to the insulator strings 5. The wire-hanging device includes a horizontal arm 2, and the end of the cross arm 2 is provided with a hook connected to the insulator string 5. The middle part of the cross-arm 2 is fixed with the fixed seat 3 of the vertical cross-arm 2,

[0029] According to attached figure 2 It can be seen that three wire hanging devices are arranged side by side, and insulator strings 5 are hung on the ends of the cross arms 2 of the wire hanging devices, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com