Power supply management method and power supply management device for electronic scale

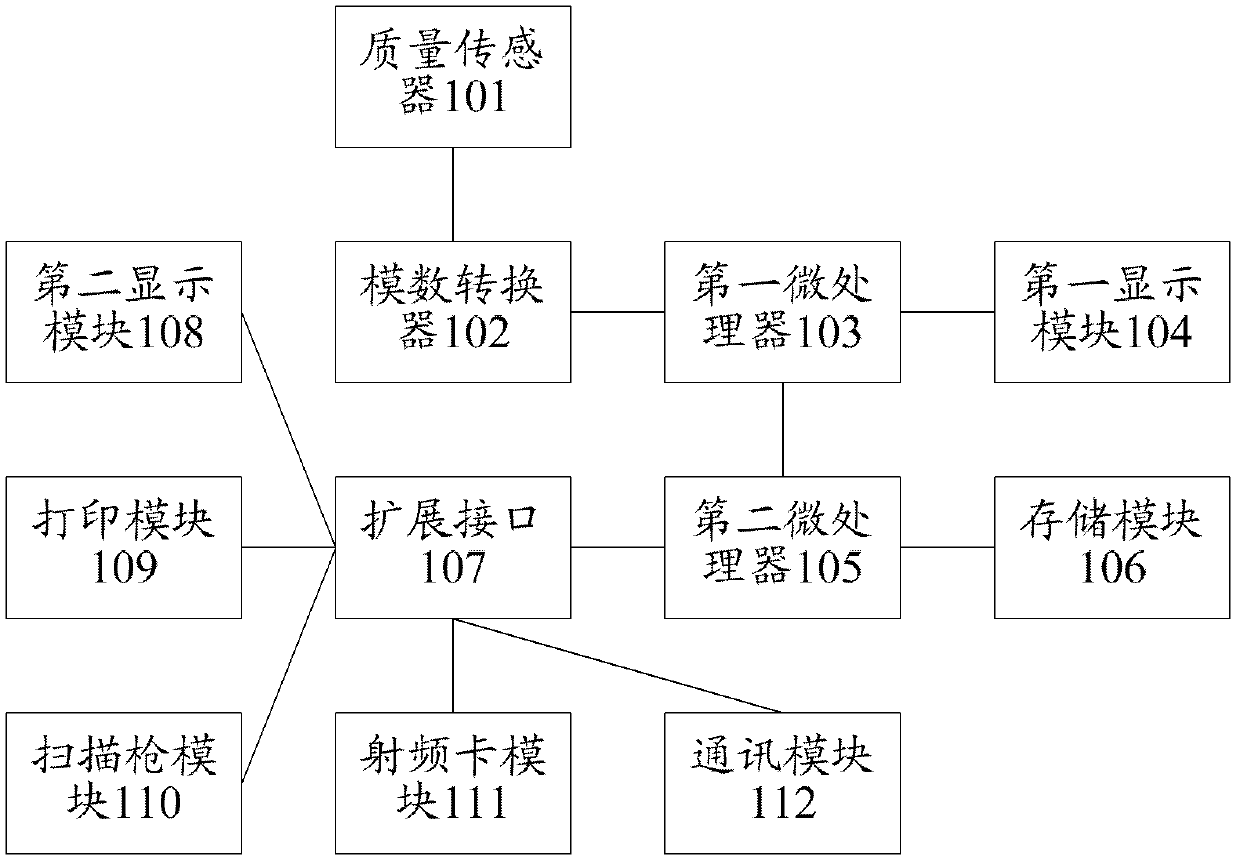

A technology for power management and electronic scales, which is applied in the field of electronics and can solve the problems of too many electronic scales and increased energy consumption of components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

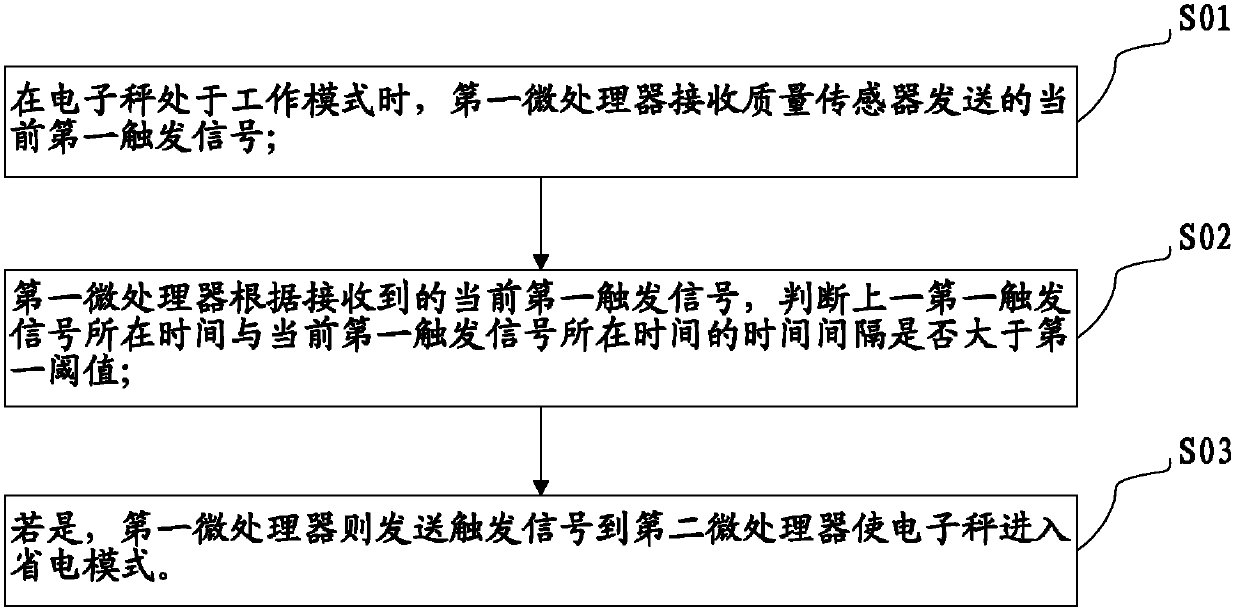

[0042] see figure 2 , in combination with the above-mentioned electronic scale, the first embodiment of the power management method of the electronic scale of the present invention includes the following steps:

[0043] Step S01: When the electronic scale is in the working mode, the first microprocessor receives the current first trigger signal sent by the quality sensor;

[0044] Step S02: The first microprocessor determines whether the time interval between the time of the last first trigger signal and the time of the current first trigger signal is greater than the first threshold according to the received current first trigger signal;

[0045] Step S03: If yes, the first microprocessor sends a trigger signal to the second microprocessor to make the electronic scale enter the power saving mode.

[0046] After entering the power saving mode, only the quality sensor 101, the analog-to-digital converter 102 and the first microprocessor 103 are in the power supply state, whil...

no. 2 example

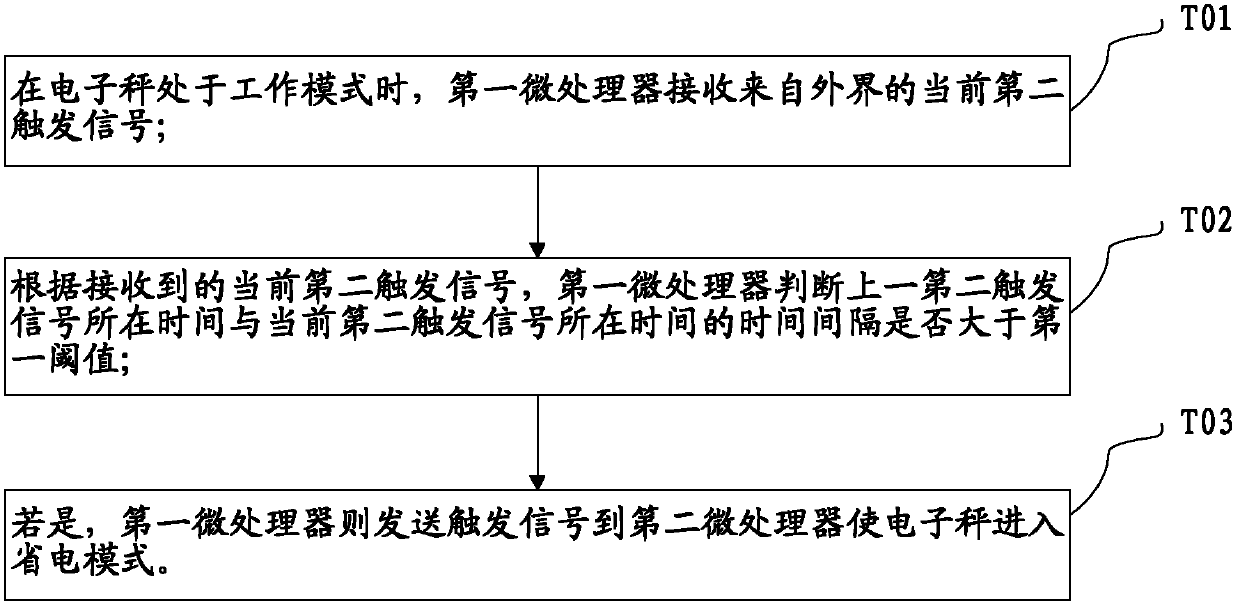

[0051] see image 3 , in combination with the above-mentioned electronic scale, the second embodiment of the power management method of the electronic scale of the present invention includes the following steps:

[0052] Step T01: when the electronic scale is in the working mode, the first microprocessor receives the current second trigger signal from the outside;

[0053] Step T02: According to the current second trigger signal received, the first microprocessor judges whether the time interval between the time of the previous second trigger signal and the time of the current second trigger signal is greater than the first threshold;

[0054] Step T03: If yes, the first microprocessor sends a trigger signal to the second microprocessor to make the electronic scale enter the power saving mode.

[0055] After entering the power saving mode, only the quality sensor 101, the analog-to-digital converter 102 and the first microprocessor 103 are in the power supply state, while the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com