Magnetorheological elastomer damper with single rod extending out

A magnetorheological elastomer and single-rod technology, applied in the field of dampers, can solve the problems of magnetorheological damper failure, difficulty in dynamic sealing, performance degradation of magnetorheological dampers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

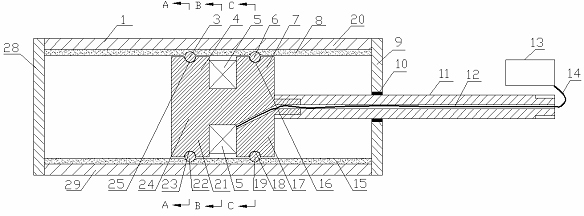

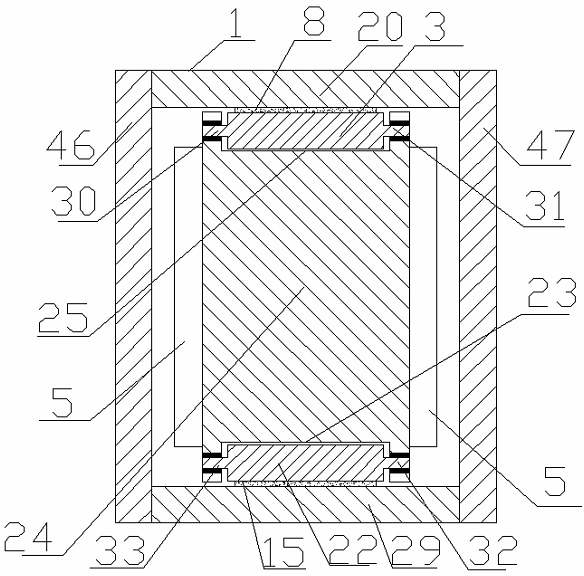

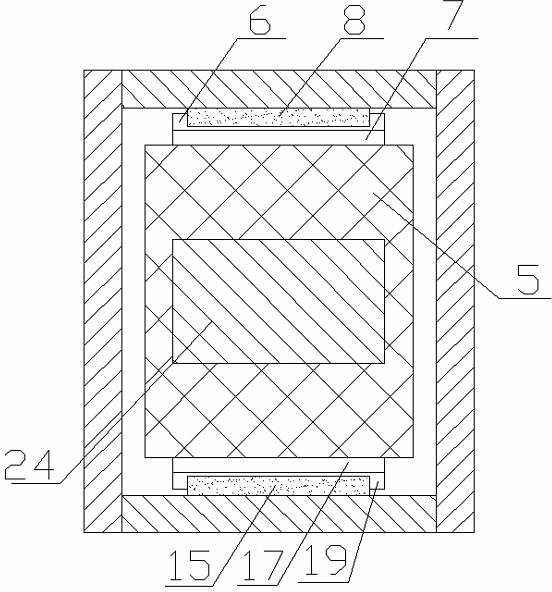

[0019] The structure of the present invention is described in detail below in conjunction with accompanying drawing:

[0020] see figure 1 , figure 2 , image 3 and Figure 4 , which is a specific structure of the present invention, a single-rod magneto-rheological elastomer damper, which includes: a damping rod 11 made of a non-magnetic material, a damping block 24 made of a magnetic material, a Four damping rollers 3, 6, 19 and 22 made of magnetic material; wherein: the cross section of the working cylinder 1 cavity is rectangular, and baffle plates 9 and 28 are fixed at both ends of the working cylinder 1, wherein the baffle plate 9 There is a hole in the middle, and a sliding bearing 10 is fixed in the hole. A layer of magnetorheological elastomers 8 and 15 are fixed on the surfaces of the two short sides 20 and 29 made of magnetically conductive materials in the working cylinder 1. The working cylinder 1 The two long sides 46 and 47 of the two long sides 46 and 47 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com