Variable-performance radial bearing formed by controllable tilting pad and bearing pad

A technology of radial bearings and pads, which is applied in the direction of shafts and bearings, rotating bearings, bearings, etc., can solve problems such as poor dynamic stability, low carrying capacity, and complex structure, and achieve the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

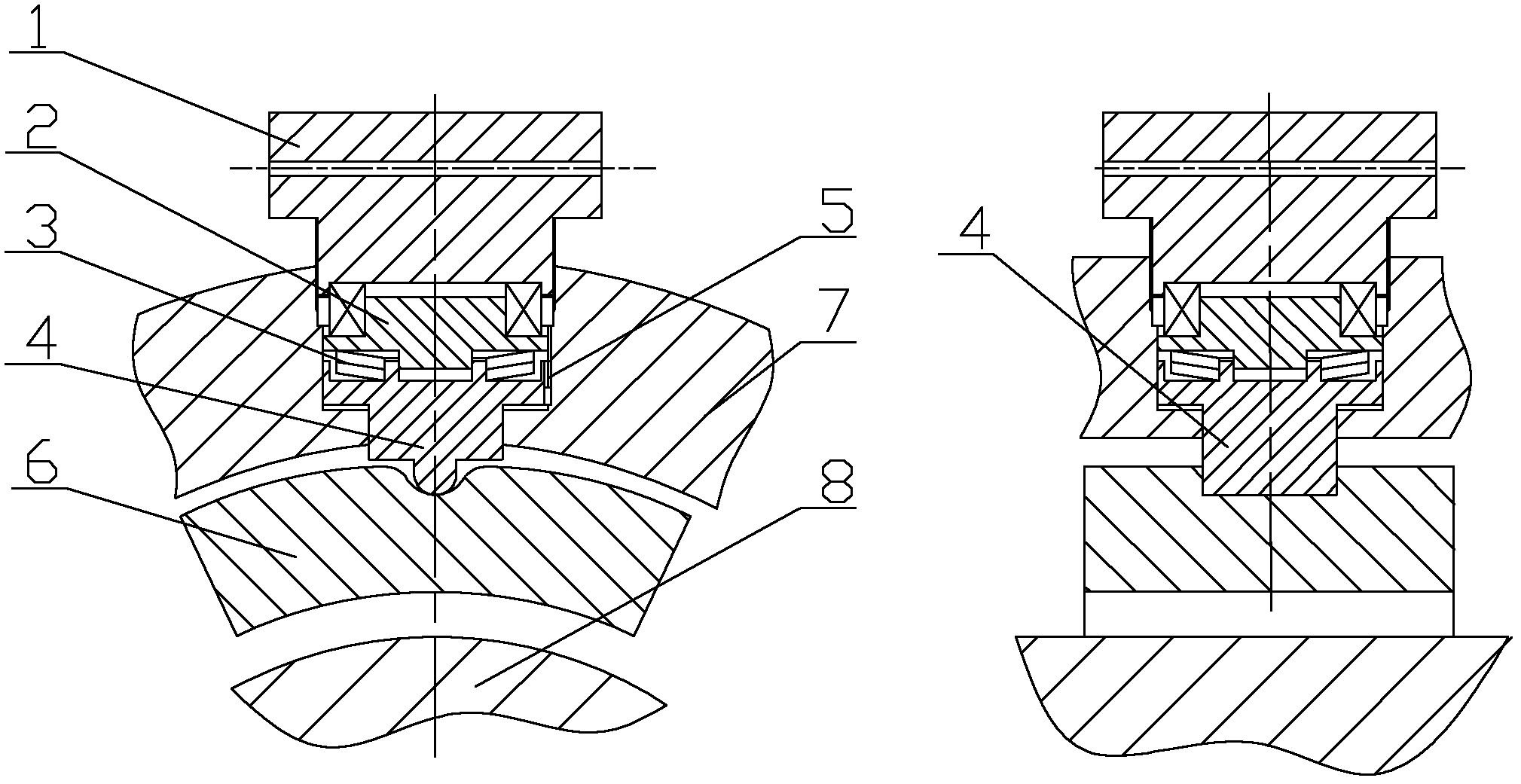

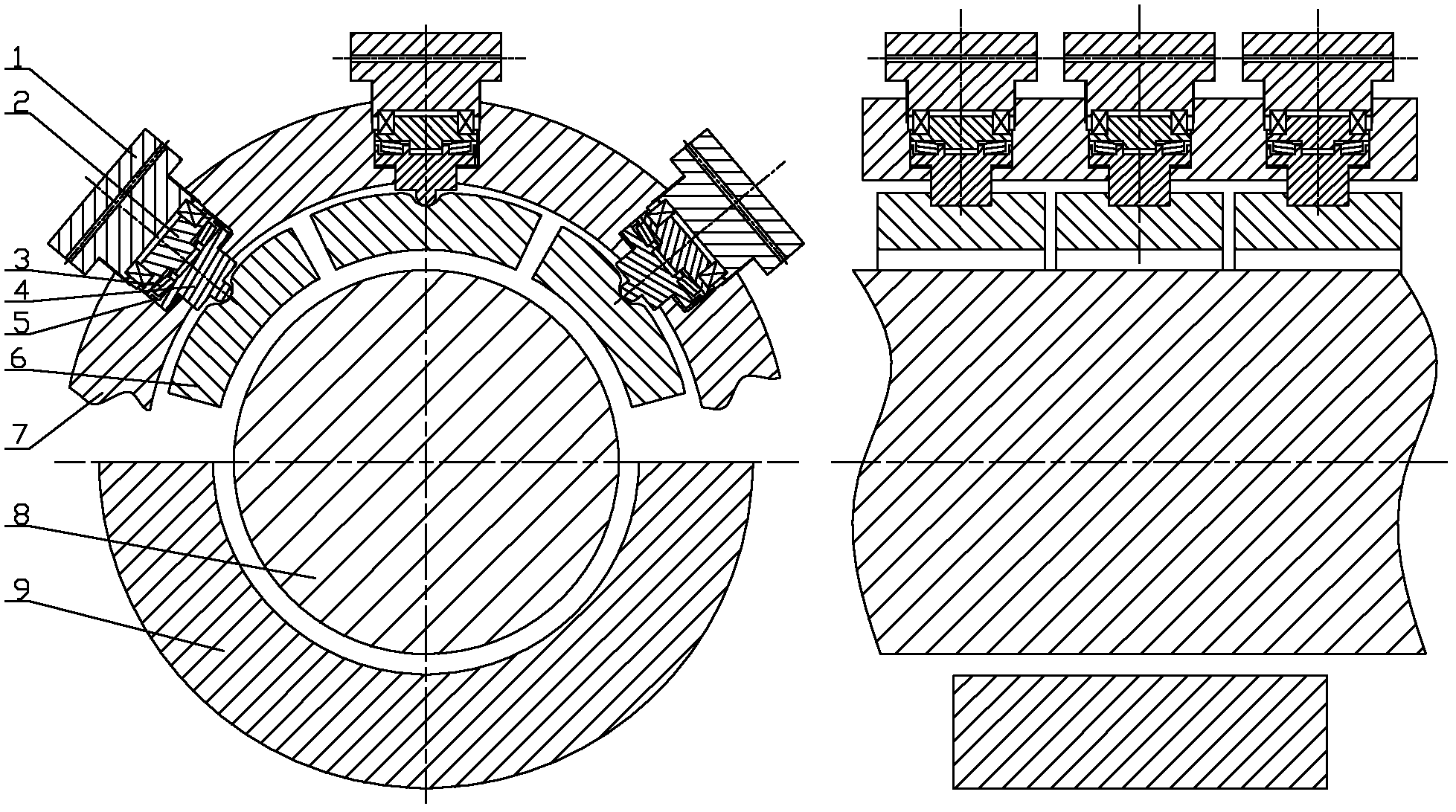

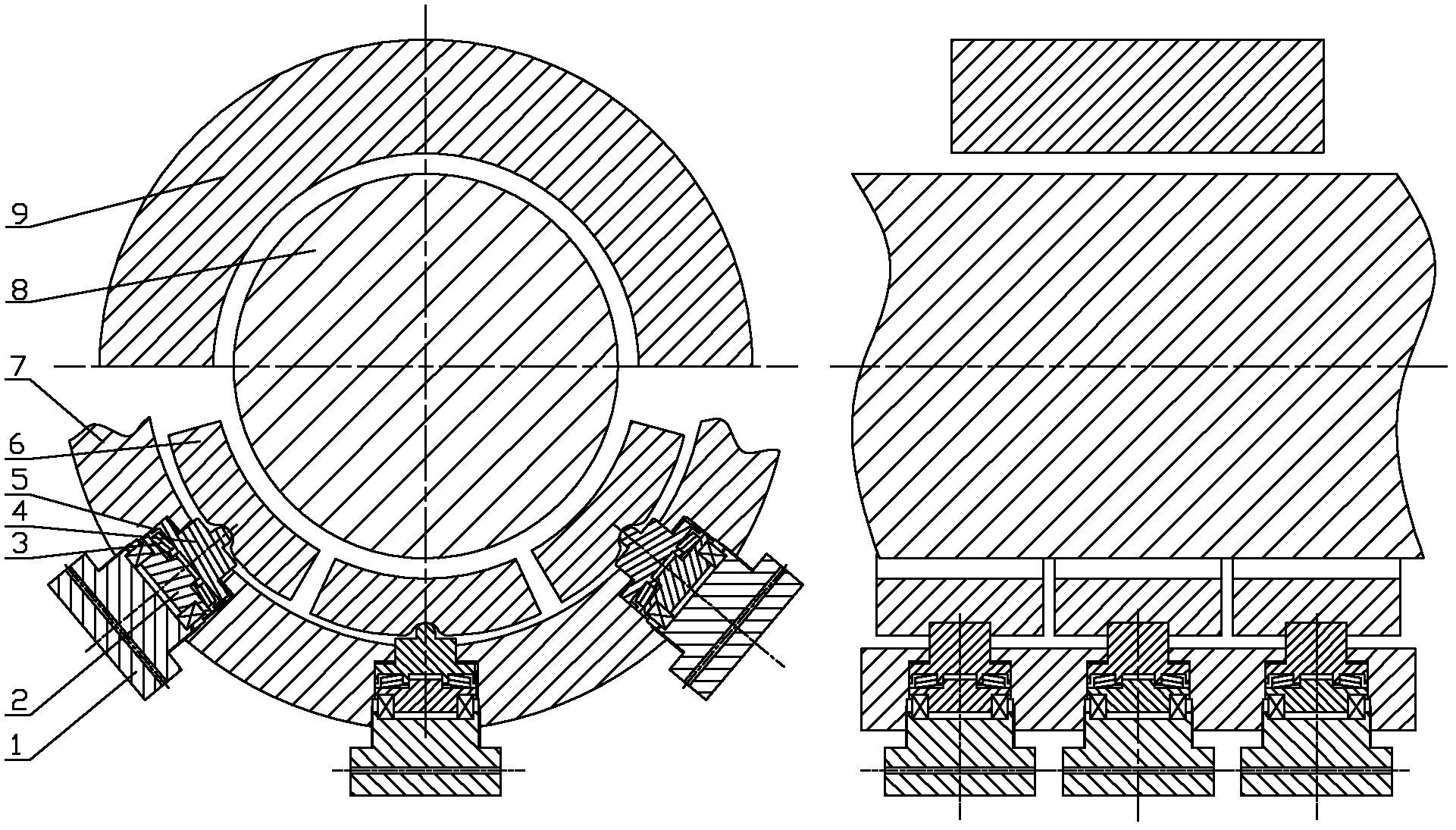

[0018] See attached figure 1 , The controllable tilting pad in the present invention is made up of adjusting screw 1, anti-rotation device 2, control spring 3, cylindrical support block 4, anti-rotation key 5, tilting pad 6 and bearing housing 7. The adjustment screw 1 and the bearing housing 7 are connected by a fine thread, and the rotation of the adjustment screw 1 can compress the control spring 3 so that the control spring 3 generates a spring deformation force, and the spring deformation force acts on the tilting pad 6 through the cylindrical support block 4 above to change the dynamic characteristics of the bearing oil film, and the coefficient of dynamic characteristics can be identified. The adjusting screw 1 has a torque when it rotates, and the twisting motion needs to be converted into a pressing motion to the control spring. A stopper 2 is arranged between the adjusting screw 1 and the control spring 3 . The spin stopper 2 includes a thrust bearing and a thrust b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com