Electronic throttle valve body of diesel engine

An electronic throttle body, diesel engine technology, applied in mechanical equipment, engine control, machine/engine, etc., can solve the problems of large one-way limit movement, easy wear of the resistance film, shortening the life of the throttle body, etc., to achieve shielding Effects of Electromagnetic Interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

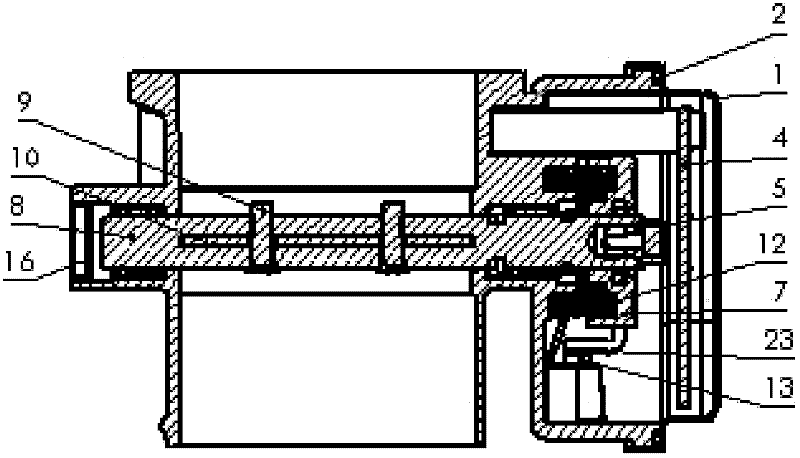

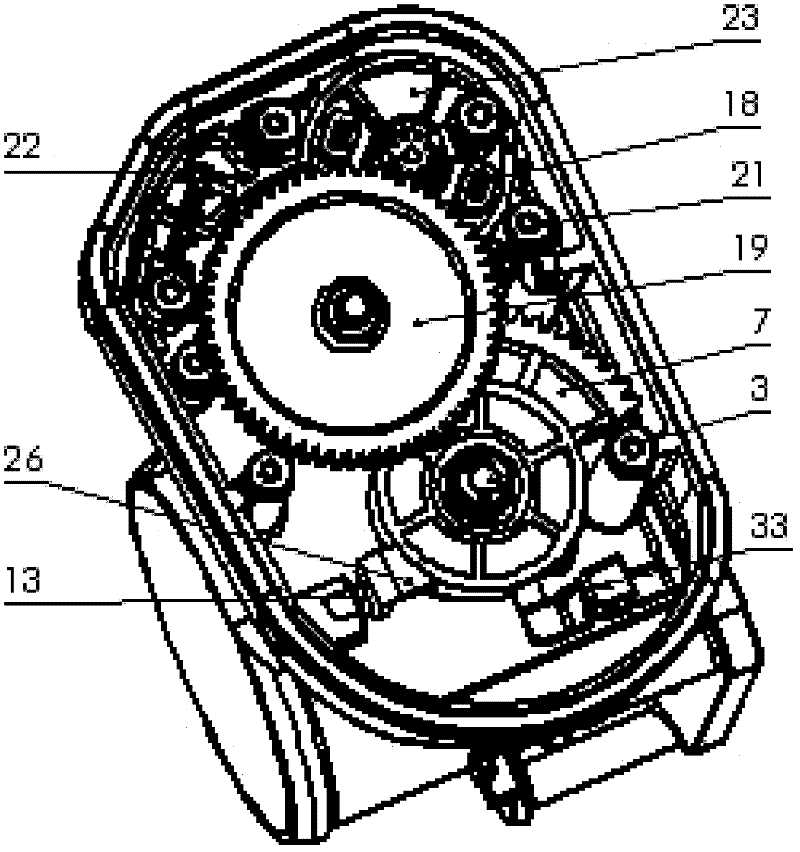

[0021] Depend on Figure 1-Figure 7 It can be seen that the present invention includes: a main body 14, a printed circuit board 4 of a control circuit, a throttle plate 10, a first bearing 11 and a second bearing 15, a throttle shaft assembly 8, a magnet assembly 5, a fully closed adjustment screw 13, and a reset gear Assembly 7, intermediate gear 19, DC motor 20, return spring 12, locking screw 3, cover 16, intermediate gear pin 17, conduction insert 18, first screw 21, external communication pin 22 and socket assembly 23 The DC motor 20 is installed in the body as a whole after the socket assembly 23, and the socket assembly 23 and the metal plate 25 are locked on the body with the first screw 21, and the second socket assembly 23 is used between the body 14 and the socket assembly 23. The sealing ring 24 prevents the entry of external liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com