Sand blasting, perforating and fracturing method

A technology for sand blasting, perforating, and sand fracturing, which is used in earth-moving drilling, fluid production, wellbore/well components, etc. Process link, avoid harm, avoid the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

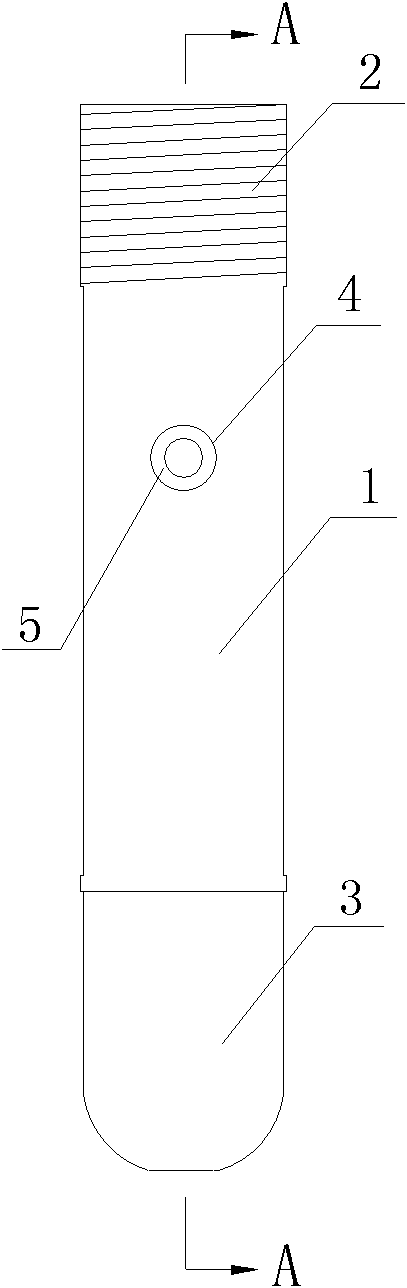

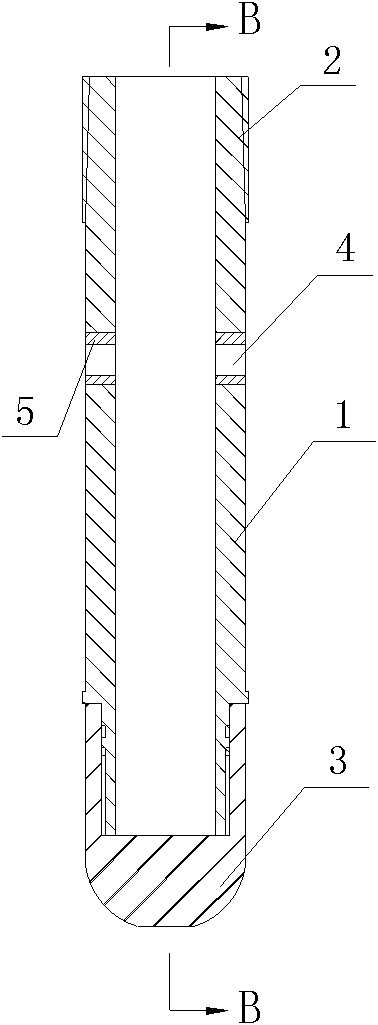

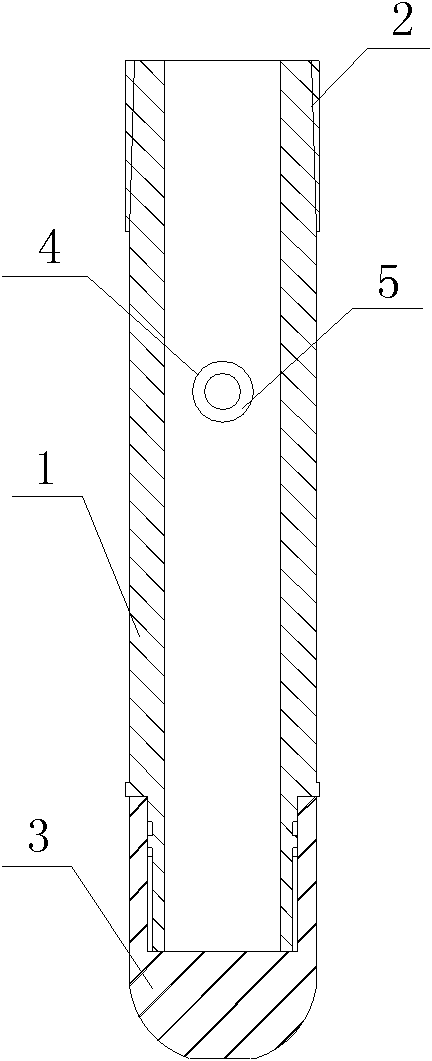

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

[0025] The sandblasting and perforating fracturing method comprises the following steps:

[0026] a. Pass the coiled tubing connected with the sandblasting perforator through the production tubing to reach the construction target layer; the specific steps include:

[0027] (a1) Lower the production tubing to the design depth in advance, and prepare the tubing hanger. The size of the commonly used production tubing is 2.875″ or 3.5″;

[0028] (a2) Install gas trees and surface fracturing pipelines;

[0029] (a3) Install the coiled tubing injection head and connect the coiled tubing to the pump truck;

[0030] (a4) connecting the blasting perforator to the coiled tubing;

[0031] (a5) Run the coiled tubing from the production tubing to the target layer, and run the coiled tubing while...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com