Railway box wagon door and railway box wagon

A railway boxcar and door technology, which is applied to railway car body parts, door devices, door/window accessories, etc., can solve the problems of poor sealing of boxcar doors and easily damaged guide rails, so as to improve technical economy, shorten vehicle length, Solve large effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

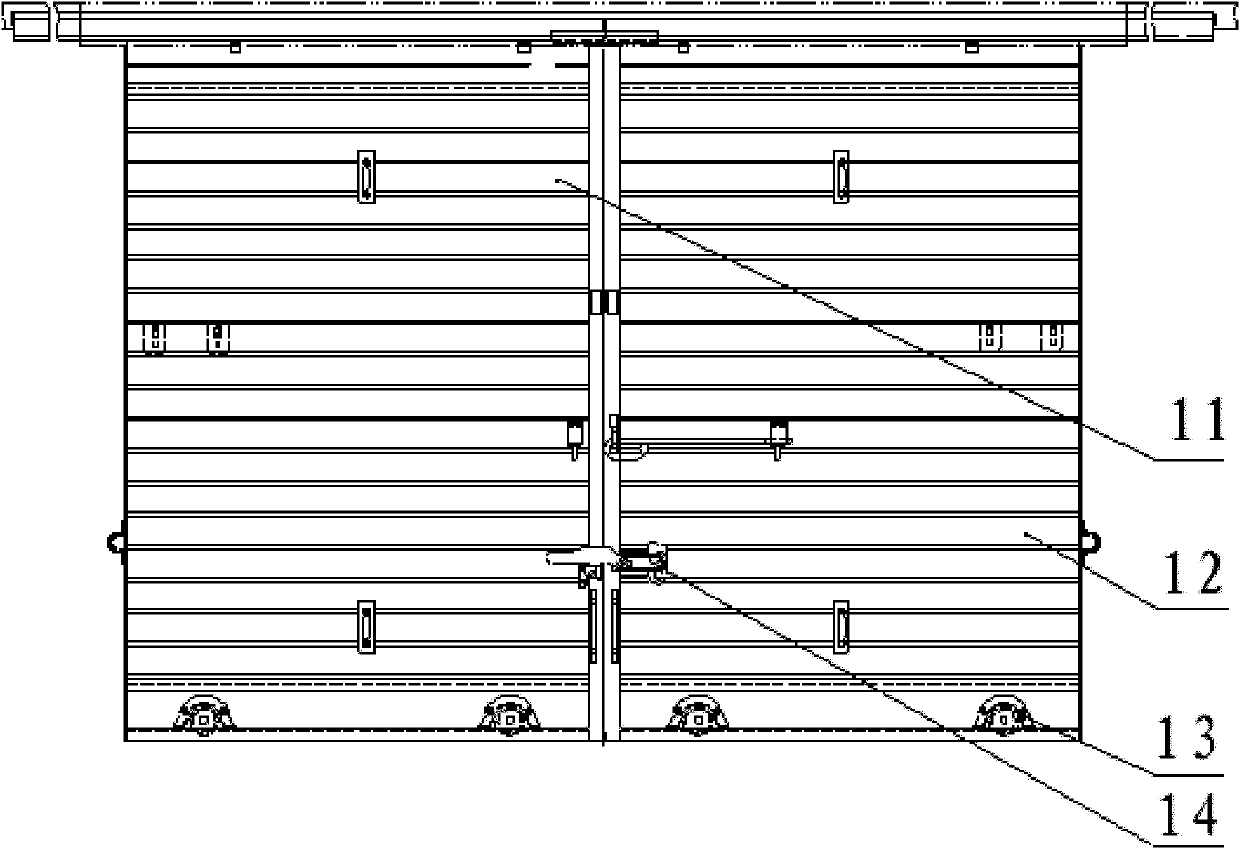

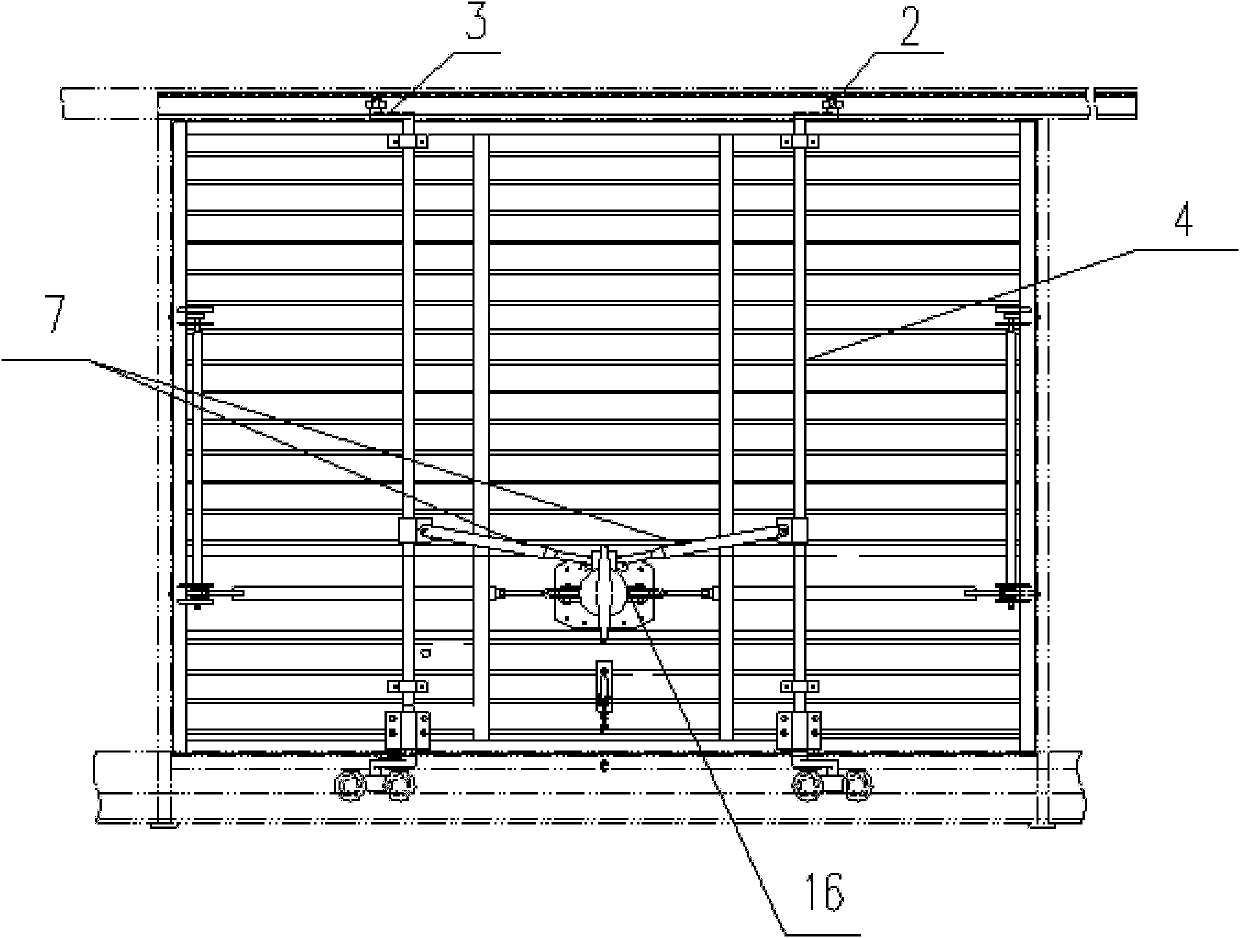

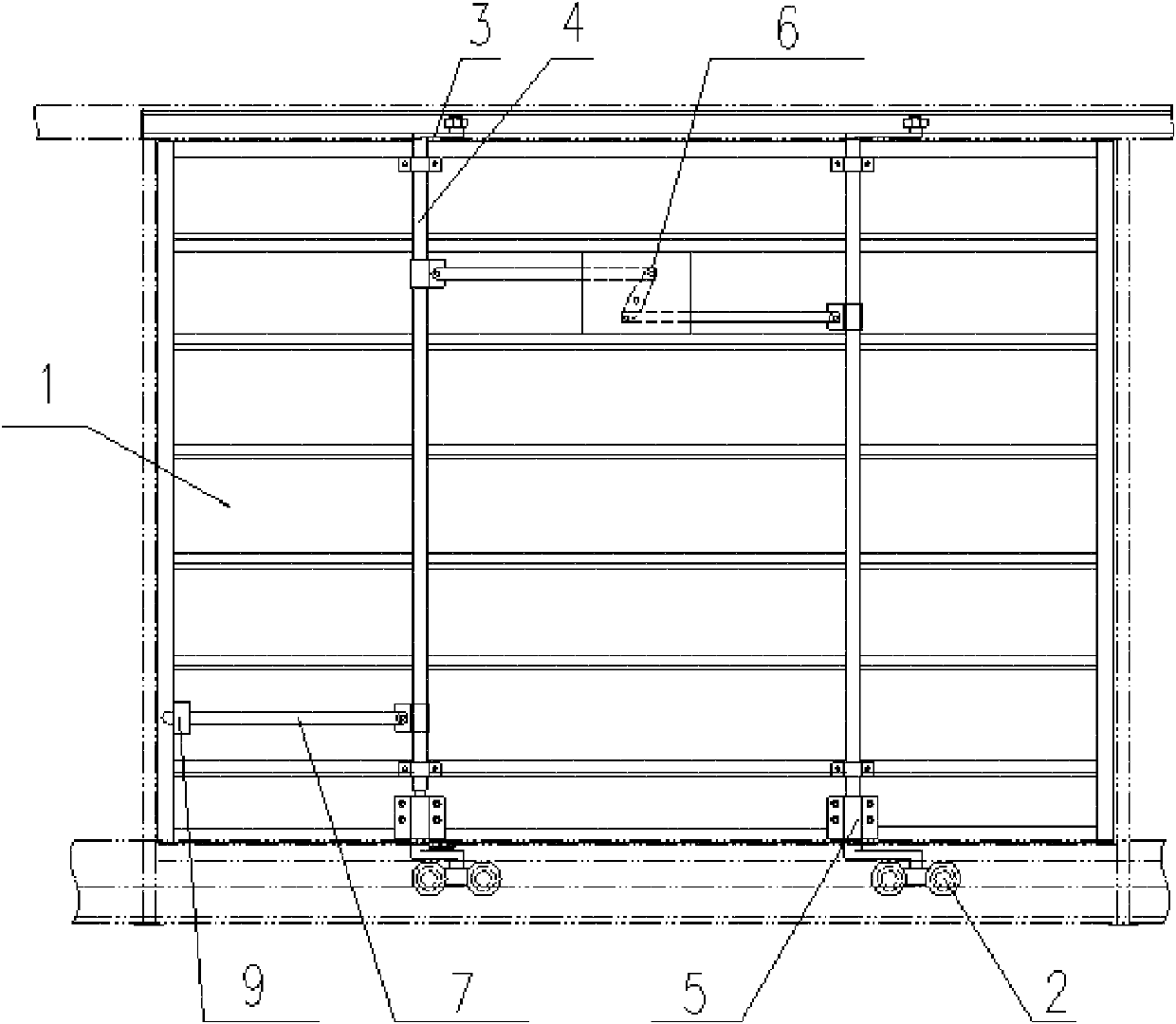

[0041] Figure 3-6 It is a schematic diagram of an embodiment of the present invention, image 3The front view of the closed state of the door of the railway box car provided by Embodiment 1 of the present invention; Figure 4 for image 3 left view of Figure 5 The front view of the opened state of the door of the railway box car provided by Embodiment 1 of the present invention; Figure 6 for Figure 5 left view of .

[0042] As can be seen from the figure, the railway boxcar door includes a door panel 1 and guide rails arranged parallel to the side wall or chassis of the boxcar. The guide rail includes an upper guide rail and a lower guide rail 10. Two groups of rotating shaft units are arranged on the door panel 1, and the rotating shaft unit consists of a shaft seat 5 and a lower rail. The main shaft 4 is composed of a shaft seat 5 fixed on the door panel 1, and the main shaft 4 is penetrated in the shaft seat 5 and is rotatable, so that the rotating shaft unit and t...

Embodiment 2

[0049] Figure 7 The front view of the railway box car door with the middle door provided for the second embodiment of the present invention; the difference from the first embodiment is that a middle door 8 that can be opened and locked from the inside of the car is provided in the middle or appropriate area of the door panel 1. Door 8 can be opened and locked in the car, which is convenient for escorts in the car to get in and out when the door is closed. The form and position of middle door 8 can be adjusted according to user requirements.

Embodiment 3

[0051] Figure 9 It is a cross-sectional view of the lower guide rail of the door of a railway box car provided by Embodiment 3 of the present invention.

[0052] The structure of the boxcar door is the same as that of the first embodiment, the difference is that the lower guide rail 10 in the third embodiment is fixed on the side wall of the boxcar through the support block 17, and the lower surface of the end of the support block 17 near the lower guide rail 10 is higher than that of the boxcar. The lower surface at one end; the lower end of the lower guide rail 10 and the side away from the box car is covered with a guard plate, which can prevent the forklift driver from inaccurately judging the distance, and the fork fork 15 of the forklift scrapes on the lower guide rail while increasing the overall rigidity of the guide rail. The lower end will cause the lower guide rail to tip over and deform, which will affect the sliding of the door and even cause the door to drop in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com