Rectangular steel tube concrete column and steel beam all-bolt connecting joint

A technology of rectangular steel pipes and concrete columns, which is applied in the direction of construction and building construction, can solve the problems of large residual stress, brittle failure, and limitation of pipe column side length, so as to reduce stress concentration and brittleness, and prevent joint performance The effect of reducing and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

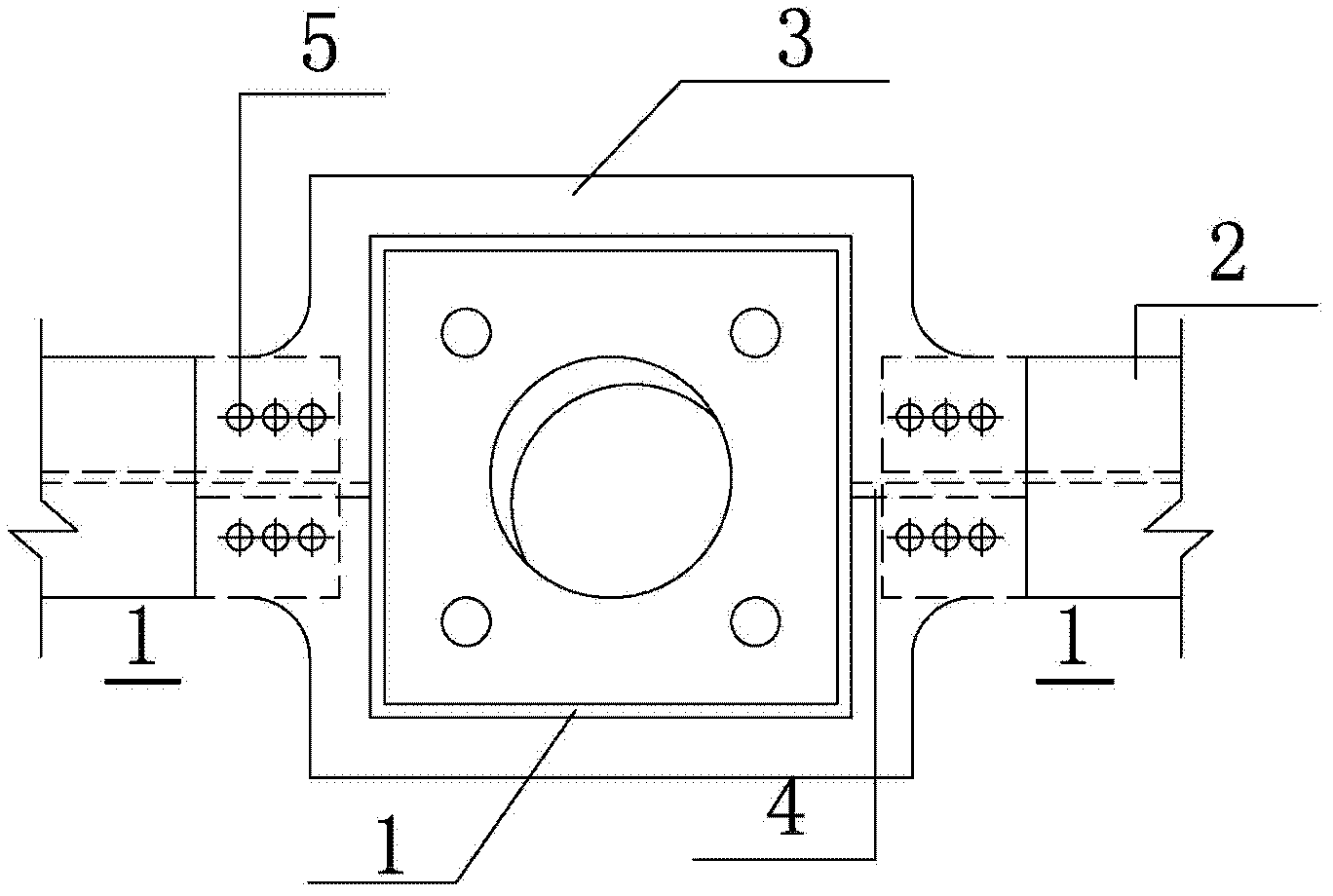

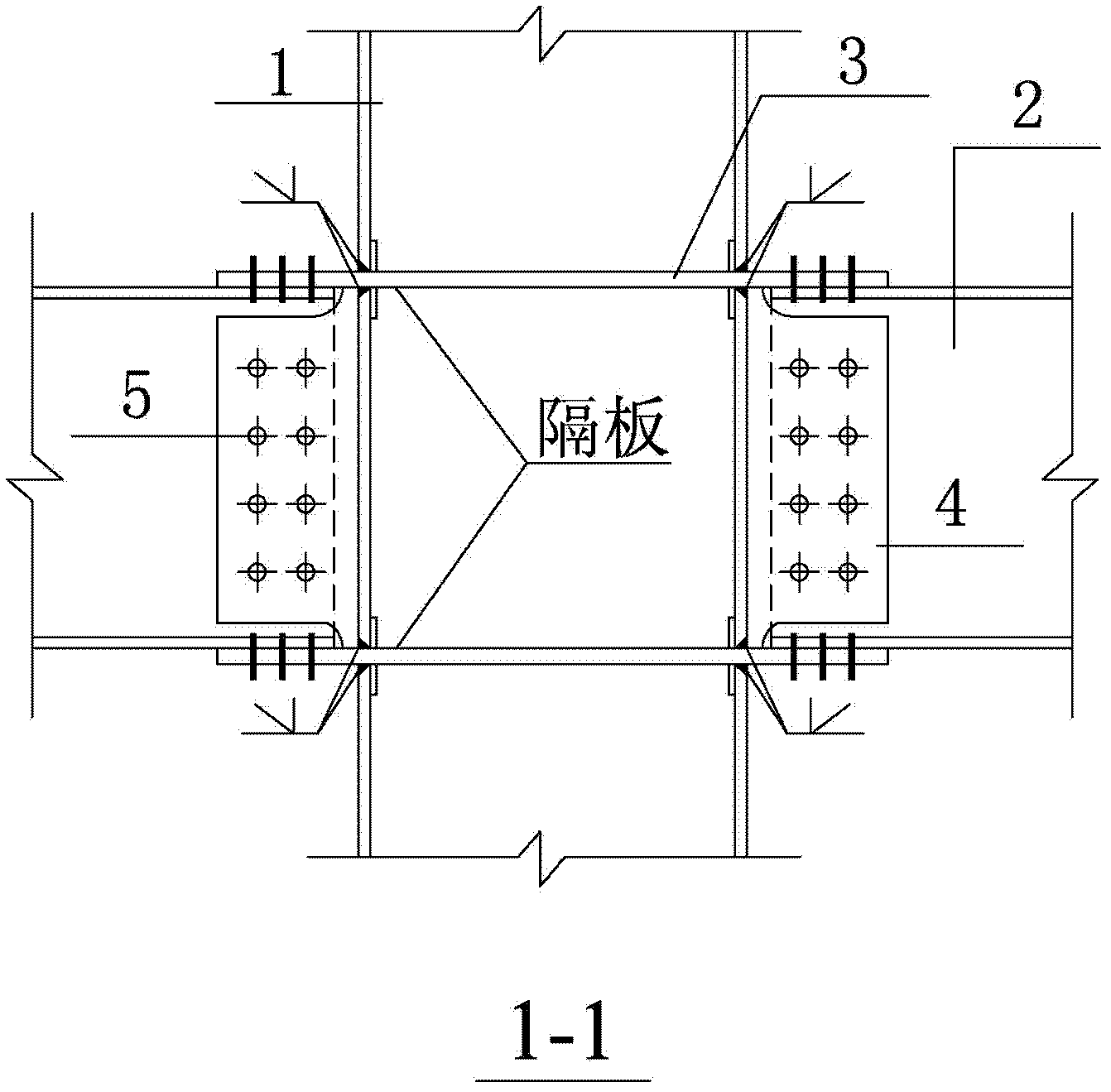

[0036] see figure 1 , figure 2 , rectangular steel pipe concrete column 1, steel beam 2, through partition 3, connection plate 4, high-strength bolt 5, wherein the through partition 3 runs through the wall of the rectangular steel pipe concrete column 1, and is welded with the surrounding wall of the steel pipe column Connection, the connecting plate 4 is welded to the side wall of the column and the upper and lower through partitions 3, the web of the steel beam 2 is bolted to the connecting plate 4, and the upper and lower flanges are bolted to the upper and lower through partitions 3 respectively. In this embodiment, the connecting plate is a connecting plate with long slots, and the upper and lower flanges of the steel beams are directly inserted into the long slots of the connecting plate.

[0037] In the above-mentioned beam-to-column connection node, the rectangular steel tube of the rectangular steel tube concrete column 1 is a welded steel plate, butt channel steel ...

Embodiment 2

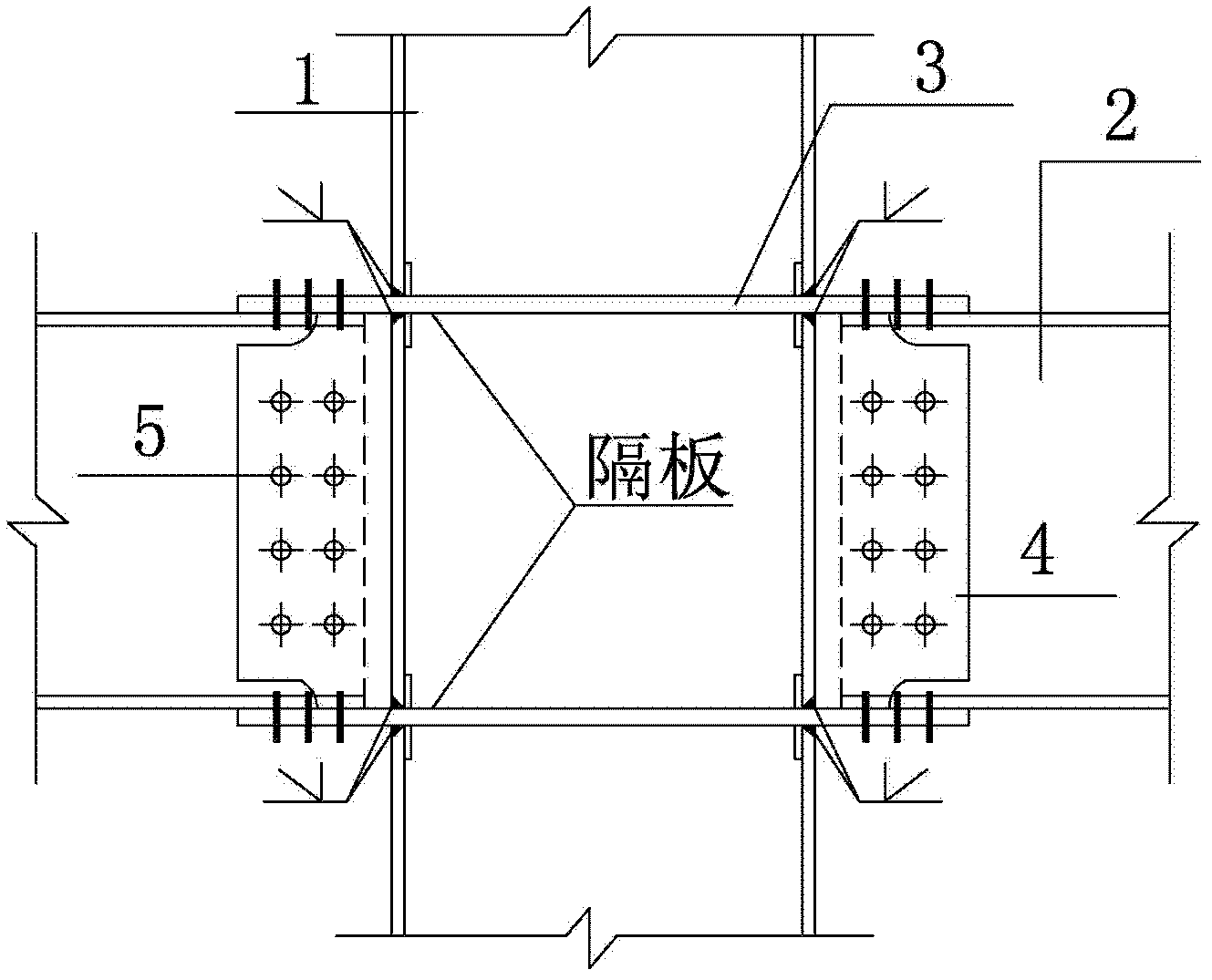

[0049] see image 3 The difference between embodiment 2 and embodiment 1 is that both the upper flange and the lower flange of the steel beam are grooved, the connecting plate has an arc-shaped cutout at the insertion opening of the steel beam, and the upper and lower flanges of the steel beam are directly inserted into the cutout of the connecting plate. When embodiment 2 is specifically used, the implementation process is:

[0050] 1) According to the size of the rectangular concrete-filled steel tube column 1, the through partition 3 is processed. On the side of the column not connected with the beam, the overhang length of the partition can be taken as 50 mm. A quarter arc with a radius of 60mm makes the partition transition to the same width as the steel beam;

[0051] 2) Bolt holes are reserved on the through partition 3, the diameter of which is slightly larger than the diameter of the high-strength bolt 5, and the number of reserved holes is calculated by the bending ...

Embodiment 3

[0058] see Figure 3-Figure 9 , the difference from Example 1 is that the steel beam in Example 3 is a steel beam with a long cut up and down on the web, and the connecting plate is a connecting plate without arc-shaped cutouts. The steel beam is located between the upper through partition according to the upper flange The upper and lower flanges are inserted under the lower through partition, and through the upper through partition and the upper side column wall, the ribs, the haunches between the lower through partition and the lower side column wall, or the upper through partition Add horizontal reinforcement plates on both sides of the slab and the lower through diaphragm to strengthen the node domain.

[0059] When this embodiment is used specifically, the implementation process is:

[0060] 1) According to the size of the rectangular concrete-filled steel tube column 1, the through partition 3 is processed. On the side of the column not connected with the beam, the over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com