Bed load sediment feeding device for river engineering model test

A river engineering model and mass-moving technology, which is applied to hydraulic models and other fields, can solve problems such as large demand for manual operations and complicated operations, and achieve the effects of high automation, high precision, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

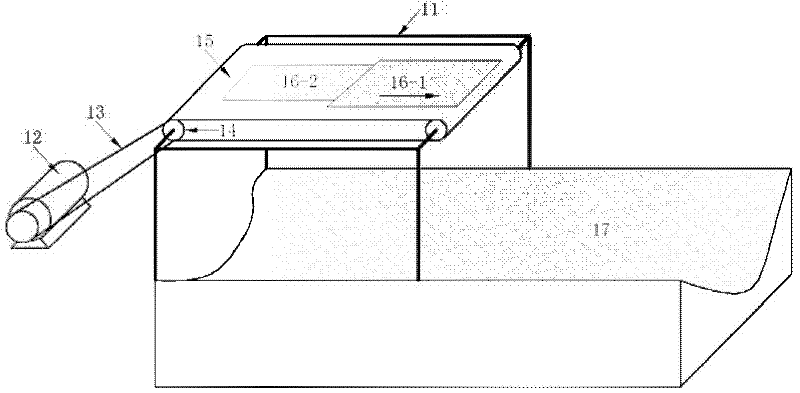

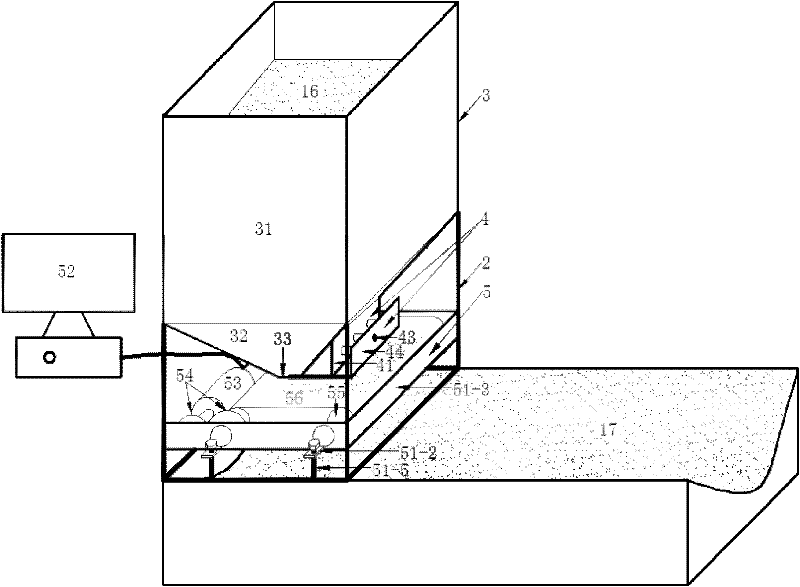

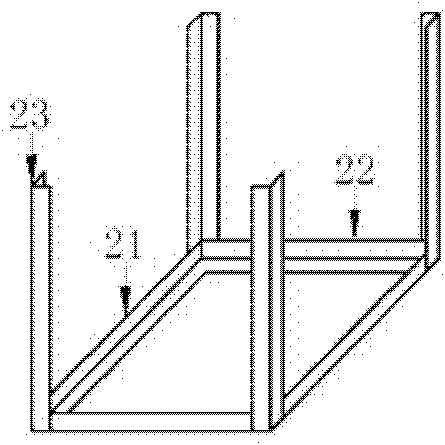

[0020] A kind of river engineering model test that the present invention proposes pushes the quality sand adding device, as figure 1 The shown is mainly composed of a bracket 2, a sand holding container 3, a throttle valve 4, and an automatic sand delivery rate control platform 5; wherein, the sand holding container is welded on the top of the support, and a throttle valve is installed at the bottom outlet of the sand holding container; the sand delivery rate The automatic control platform is installed below the outlet at the bottom of the sand holding container, and the device is installed above the channel 17 of the river engineering model when the device is applied.

[0021] The specific implementation and function of each part of the above-mentioned device are described respectively as follows in conjunction with the accompanying drawings:

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com