Cleaning machine for purifying and electrically drying seed cotton

A cleaning machine and seed cotton technology, which is applied in mechanical treatment, fiber treatment, textile and papermaking, etc., to achieve the effects of simplifying the installation process, reducing equipment investment costs, and reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

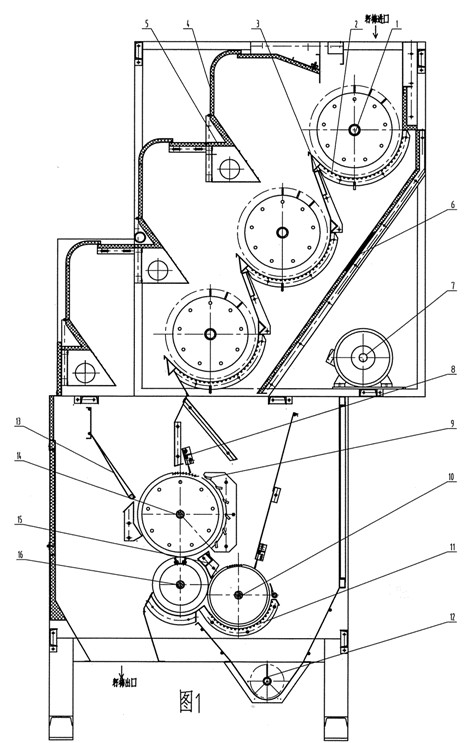

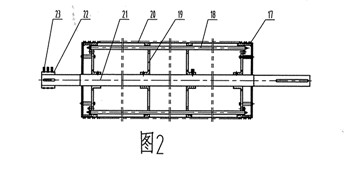

[0027] according to figure 1 , figure 2 As shown, a seed cotton cleaning machine for cleaning and electric drying includes a frame provided with a seed cotton inlet and a cotton outlet, and a drying and cleaning device inside the frame; the drying and cleaning device consists of a hot air device and multiple sets of electric Consists of heated nailing rollers, each group of electrically heated nailing rollers 1 is provided with trash removal grids 2, and the trash removal grids are connected by baffles 3; inside the rack and directly below the drying and cleaning device A cleaning device for removing bell shells or stiff petals is also provided; both the drying cleaning device and the cleaning device are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com