A substrate carrying device and substrate processing equipment using the device

A substrate carrying and substrate technology, applied in the direction of chemically reactive gas, gaseous chemical plating, crystal growth, etc., can solve the problem of increased difficulty in the design and control of airflow field and temperature field, stability and uniformity of epitaxy process Unfavorable effects, difficulty in pallet processing and increased processing costs, etc., to achieve the effect of ensuring process stability and uniformity, ensuring stability and uniformity, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

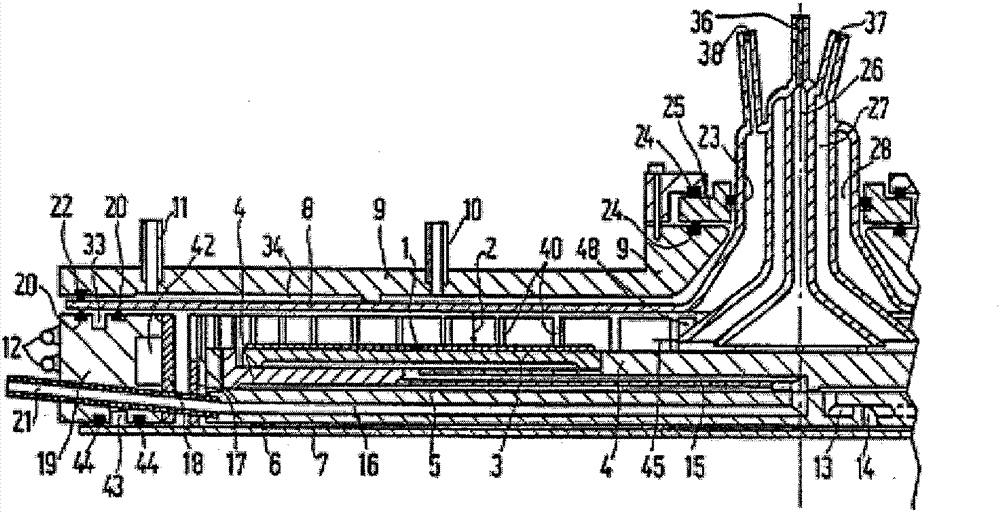

[0041] In order for those skilled in the art to better understand the technical solution of the present invention, the substrate carrying device provided by the present invention and the substrate processing equipment using the substrate carrying device will be described in detail below with reference to the accompanying drawings.

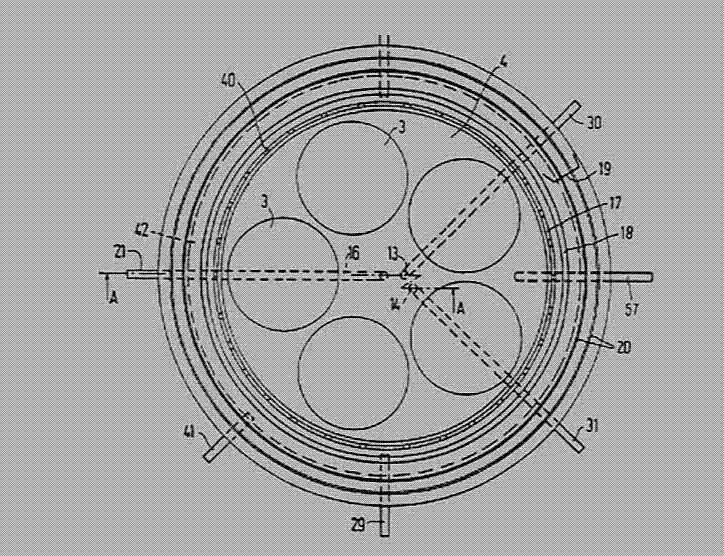

[0042]The substrate carrying device provided by the present invention is used to carry the substrate in the substrate processing equipment, the substrate carrying device includes at least one tray, and each tray has two opposite disk surfaces for carrying the substrate; That is to say, both sides of each tray can be used to carry substrates, so that compared with a substrate carrying device of the same size, it can carry more substrates at one time; therefore, the substrate carrying device has a stronger Carrying capacity, when applied to process equipment, can effectively improve the production capacity of process equipment.

[0043] see image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com