Electrolytic ozone generating device for recycling cathode water

An ozone generating device and ozone generator technology, applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems of wasting water resources, frequent replenishment of pure water, etc., and achieve the effect of reducing the number of replenishments, simple and practical structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

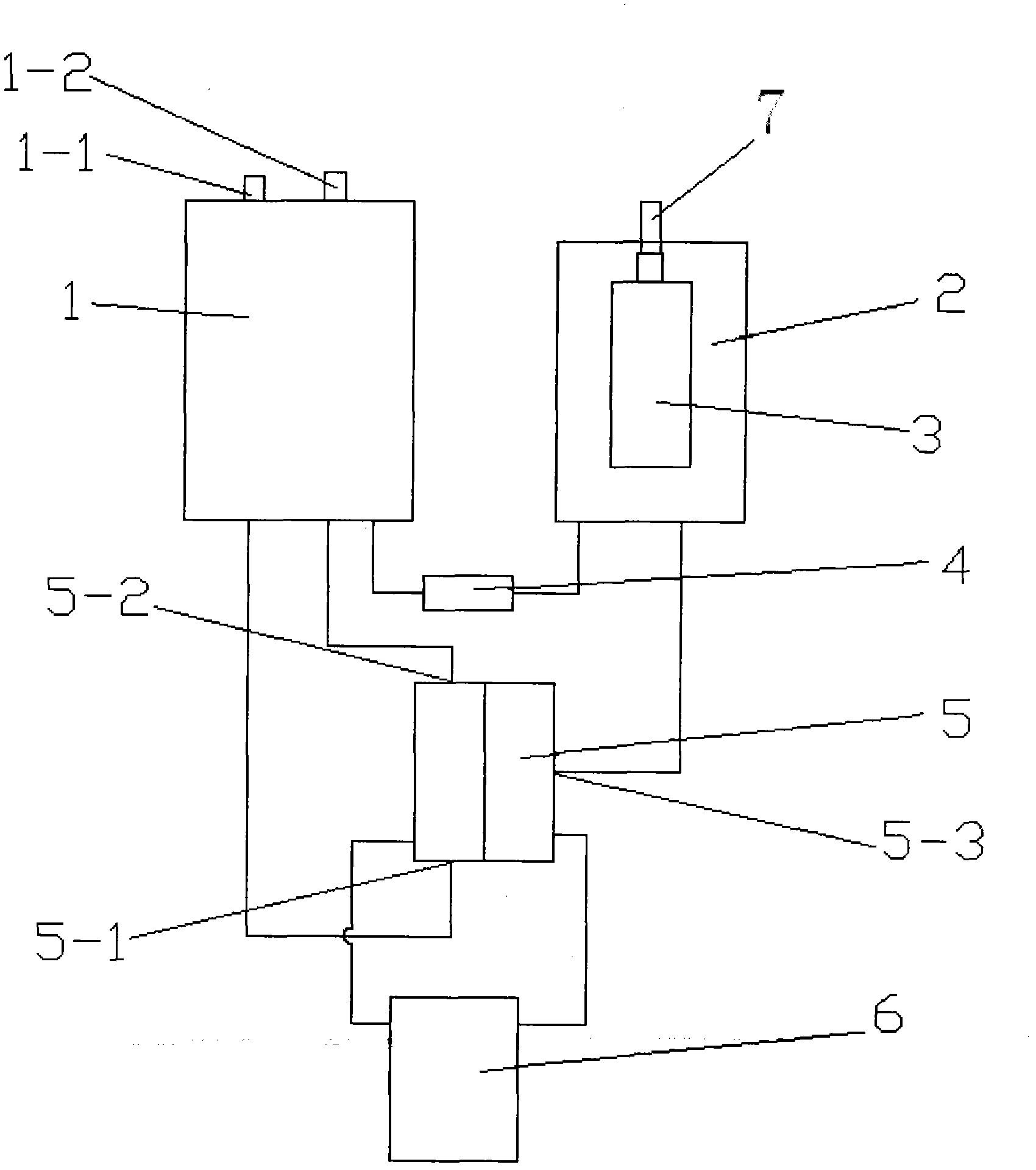

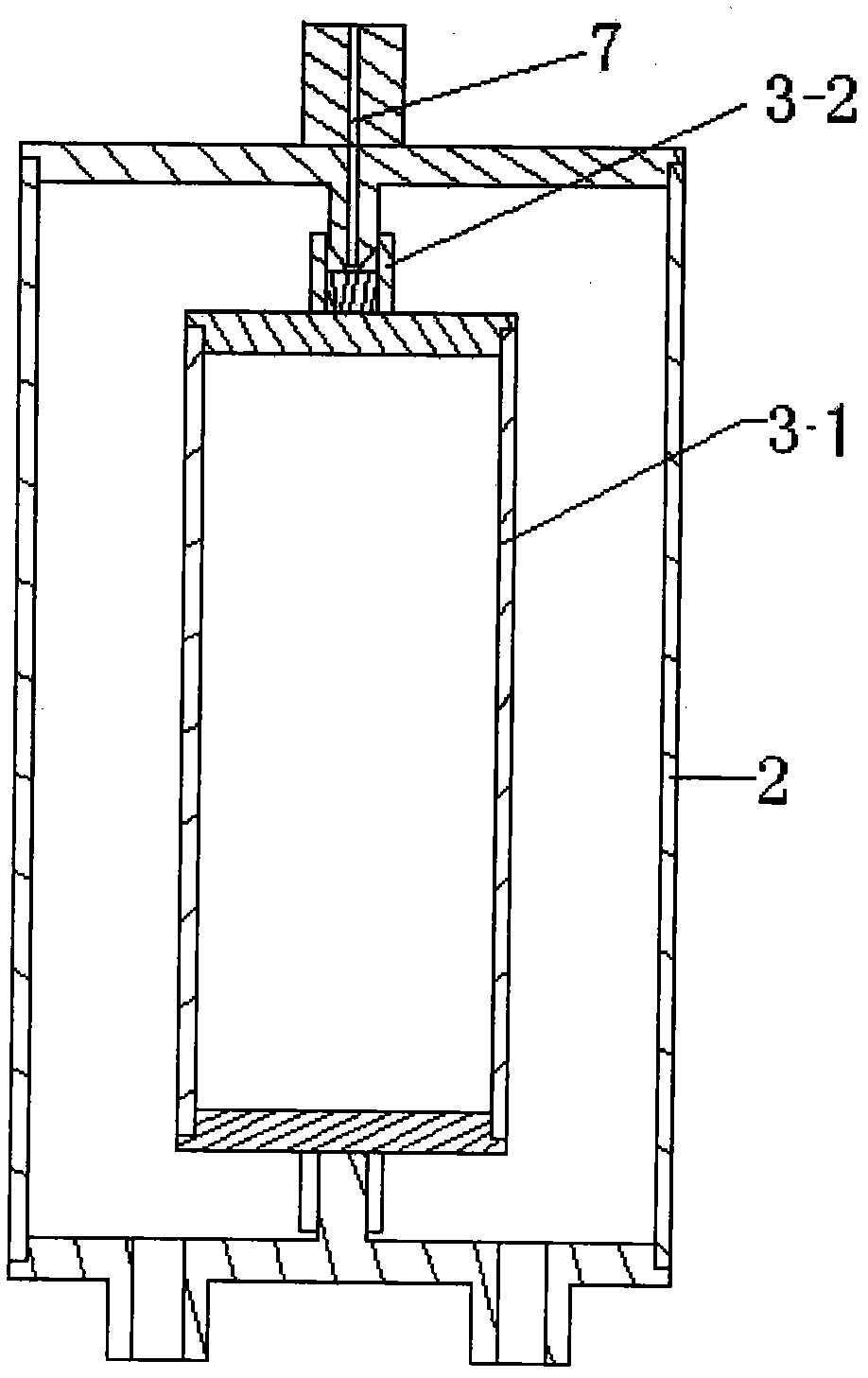

[0015] Embodiment 1: a kind of electrolytic type ozone generator (referring to figure 1 , figure 2 ), it includes an anode pure water bucket 1, which is provided with a water inlet 1-1 and an air outlet 1-2 on the anode pure water bucket 1, and the water outlet of the anode pure water bucket 1 passes through the pipeline and the anode water inlet 5- of the electrolytic ozone generator 5 1 connected, the anode gas outlet 5-2 of the electrolytic ozone generator 5 is connected to the air inlet of the anode pure water bucket 1 through a pipeline, the anode and cathode of the electrolytic ozone generator 5 are respectively connected to the positive and negative poles of the generator power supply 6, and the anode is pure The lower end of the bucket 1 is connected to the water outlet at the lower end of the cathode pure water bucket 2 through the one-way valve 4. The cathode pure water bucket 2 is provided with an exhaust port 7, and the cathode gas outlet 5-3 of the electrolytic o...

Embodiment 2

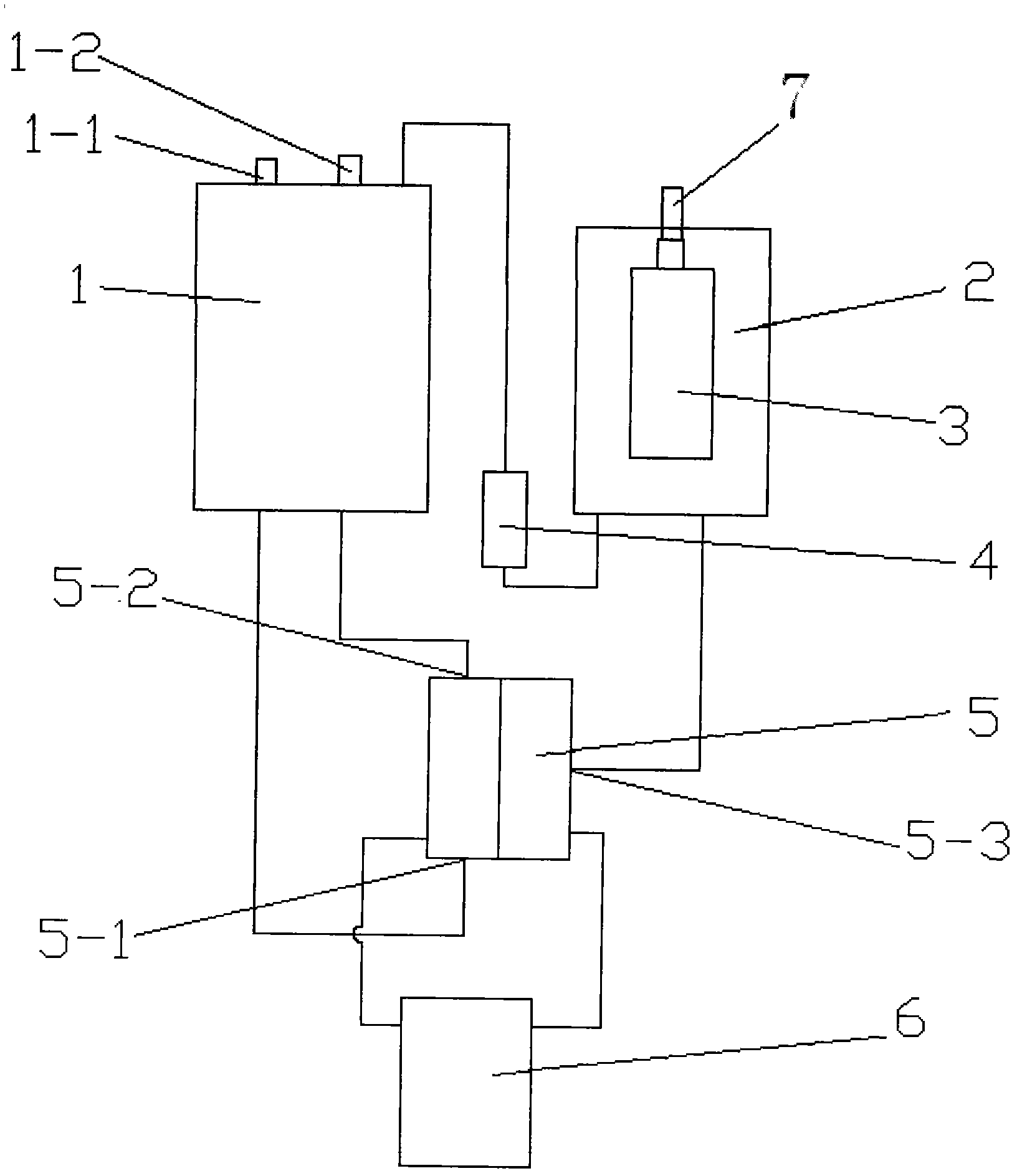

[0017] Embodiment 2: a kind of electrolytic type ozone generator (referring to image 3 , figure 2 ), its structure is basically the same as that of embodiment 1, the difference is that the anode pure water bucket 1 is connected to the water outlet at the lower end of the cathode pure water bucket 2 through the check valve 4 at the upper end, when the anode pure water bucket 1 is connected with the cathode pure water bucket 1 through the check valve 4 at the upper end When the water outlet at the lower end of the water bucket 2 is connected, since the upper end of the anode pure water bucket 1 has gas all the time, the electrical insulation between the anode and the cathode can be better ensured when the generator stops working.

Embodiment 3

[0018] Embodiment 3: a kind of electrolytic type ozone generator (referring to Figure 4 , figure 2 ), its structure is basically the same as that of embodiment 1, and its difference is that the cathode air outlet 5-3 of the electrolytic ozone generator 5 is connected to the air inlet water inlet on the upper end of the cathode pure water bucket 2 through the pipeline, when the anode pure water bucket 1 passes through the one-way When the valve 4 is connected to the water outlet at the lower end of the cathode pure water bucket 2, since there is always gas at the upper end of the cathode pure water bucket 2, the electrical insulation between the anode and the cathode can be better ensured when the generator stops working.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com