Integral process and device for crushing, drying, forming and upgrading lignite containing moisture

An integrated, brown coal technology, applied in the petroleum industry, solid fuels, fuels, etc., can solve the problems of complex process systems, no good breakthroughs, and large footprints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

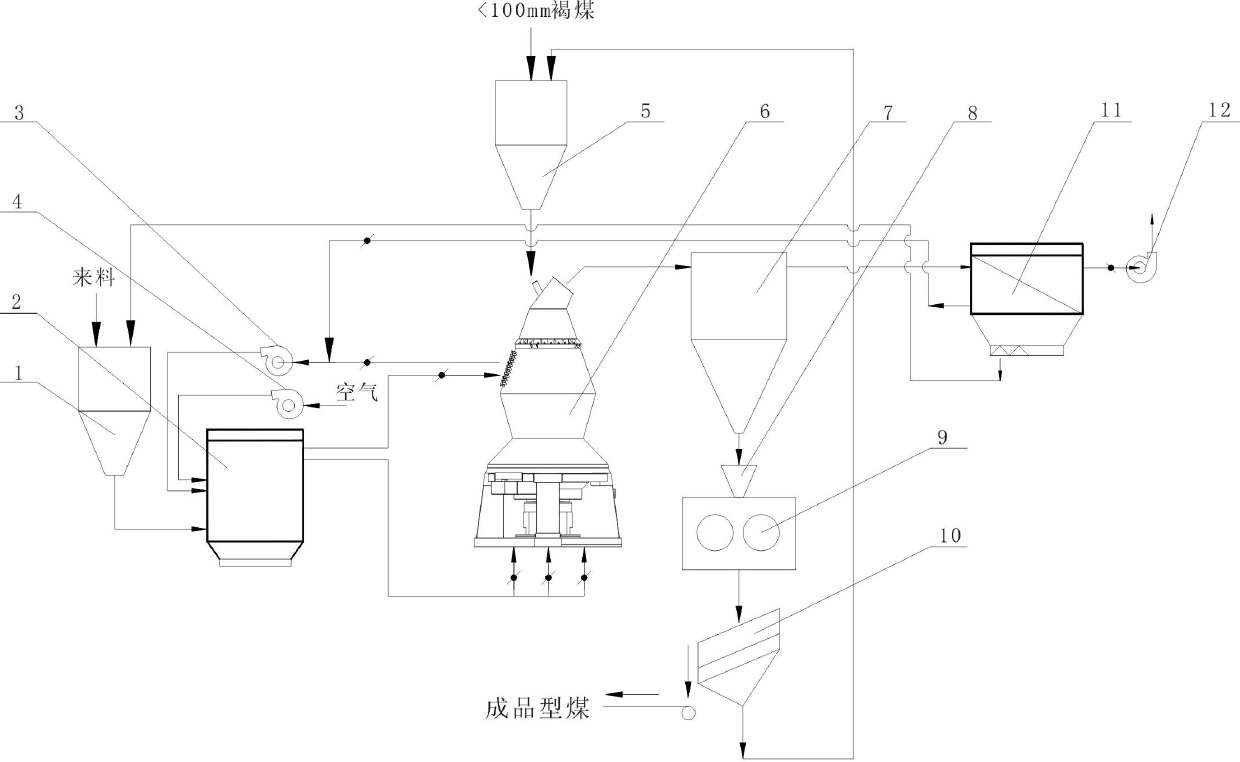

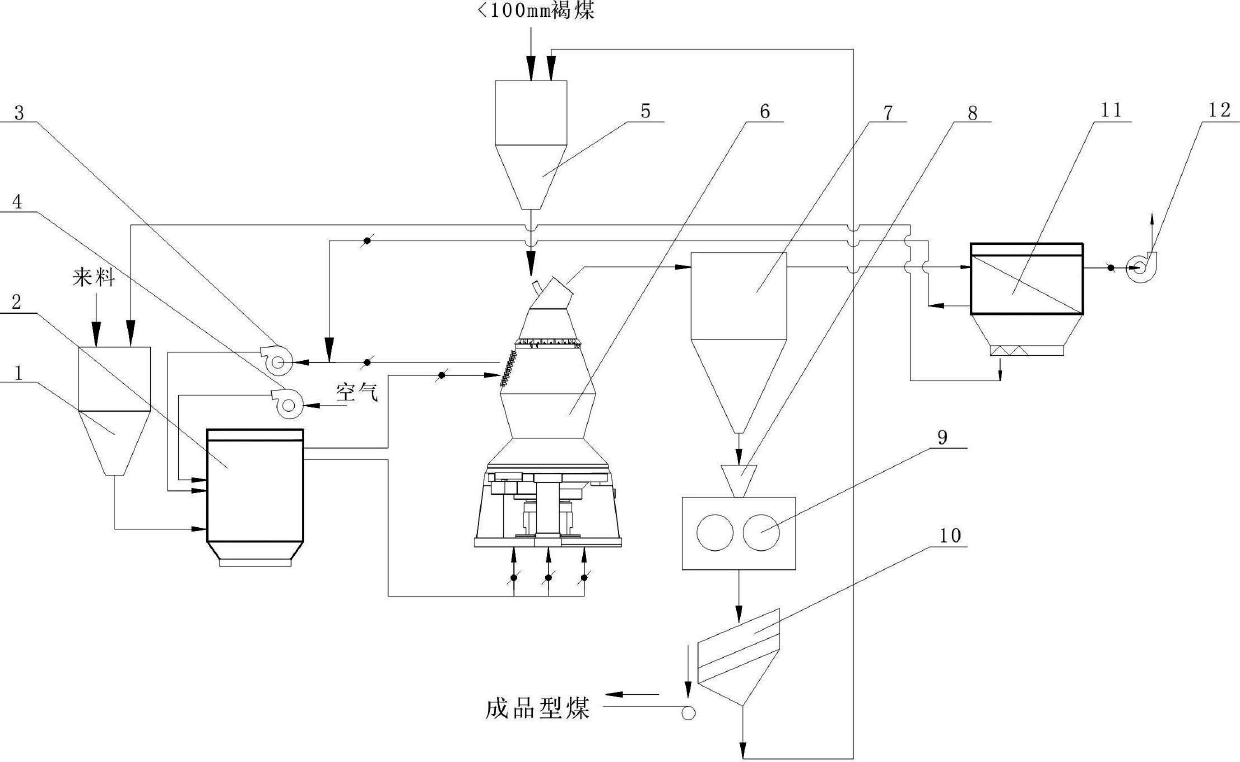

[0021] The technical solution of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0022] like figure 1 As shown, the present invention is rich in water lignite integrated crushing, drying, forming and upgrading equipment, which mainly includes a flue gas system, a raw material bin 5, an integrated crushing and drying device 6, a cyclone separator 7, a pre-pressing screw device 8 and a high-pressure forming machine 9. The flue gas system includes a flue gas furnace 2, the feed port of the flue gas furnace 2 is connected to the front warehouse 1 through a pipeline, the inlet of the flue gas furnace 2 is connected to the primary fan 4, and the gas outlet of the flue gas furnace 2 passes through The pipelines are respectively connected to the side wall and the bottom of the integrated crushing and drying device 6; the raw material bin 5 is located above the integrated crushing and drying device 6, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com