Biological aerated filter

A biological aerated filter and aeration tube technology, applied in sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as mud collection and long backwashing time in water distribution areas , to achieve the effect of increasing the water output and shortening the backwashing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with specific embodiments, where the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

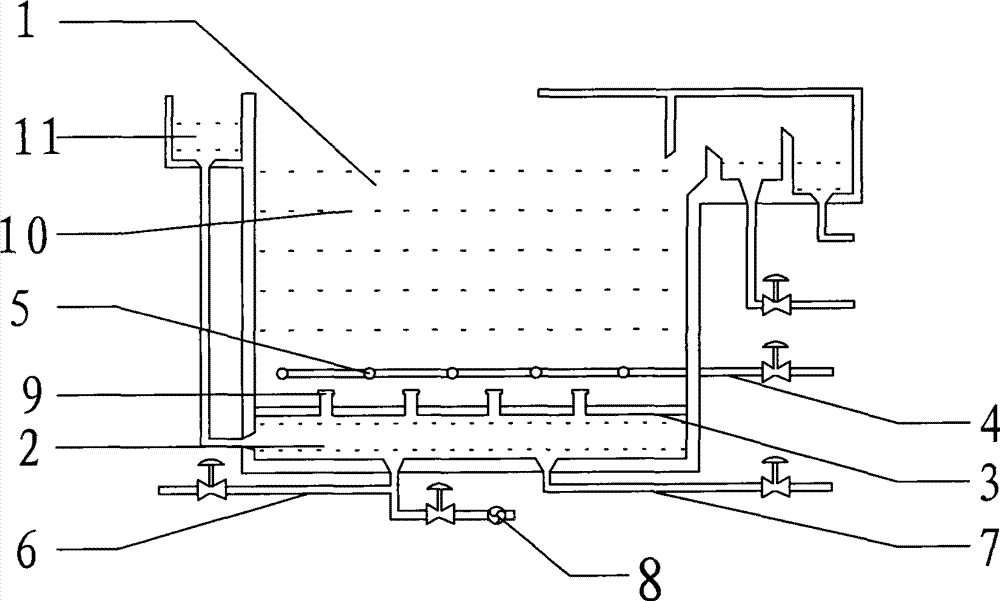

[0014] Such as figure 1 As shown, the biological aerated filter has an up-and-down structure as a whole, the upper space is the water distribution area 1 for sewage treatment, the water distribution area 1 is below the water intake area 2, and the water distribution area 1 and the water intake area 2 are separated by a partition 3; The bottom of the water distribution area 1 is provided with an air explosion pipe 4 introduced from the outside, the air explosion pipe 4 contains oxygen, and the part of the air explosion pipe 4 located in the water distribution area 1 is provided with five air diffusers 5;

[0015] Located outside the water inlet area 2 below the water distribution area 1, there are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com