Character anti-counterfeiting gilding film and manufacture process thereof

A production process and bronzing film technology, applied in the field of anti-counterfeiting, can solve the problems of large-scale counterfeiting, difficult management, backward holographic anti-counterfeiting technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

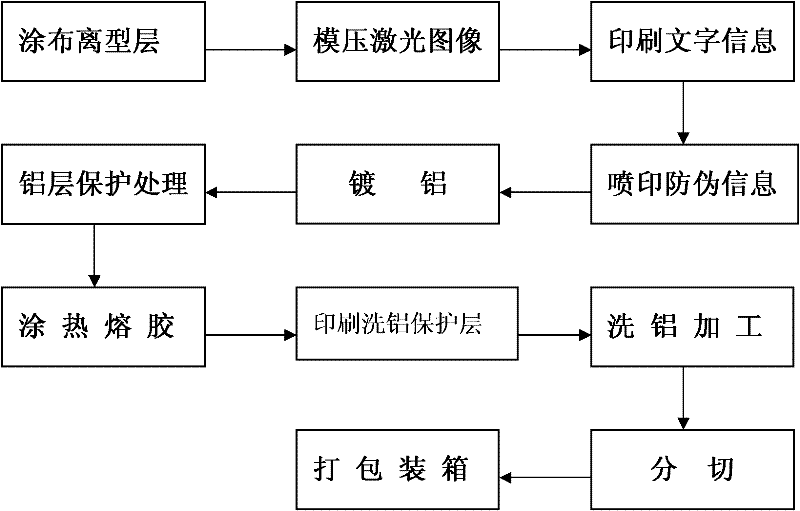

[0021] The specific implementation manner of the present invention will be further described in detail below in conjunction with the drawings and specific examples.

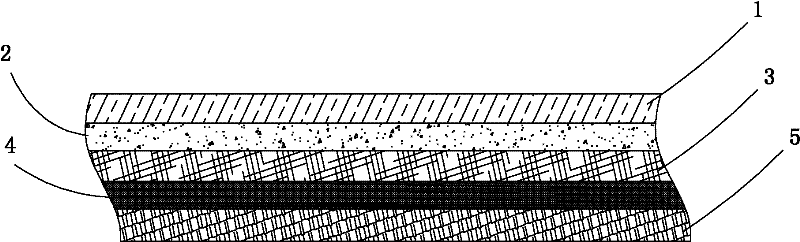

[0022] The invention provides a text anti-counterfeit bronzing film, which sequentially comprises a transfer adhesive layer, an aluminum layer protection layer, an aluminum layer, a text information layer, a release layer and a substrate medium layer, the transfer adhesive layer is a hot melt adhesive, The text information layer includes printed basic information and spray-printed text anti-counterfeiting features, and the release layer includes common transfer paint and laser molding paint.

[0023] The substrate medium layer is preferably a PET film with a thickness of 10-20 μm.

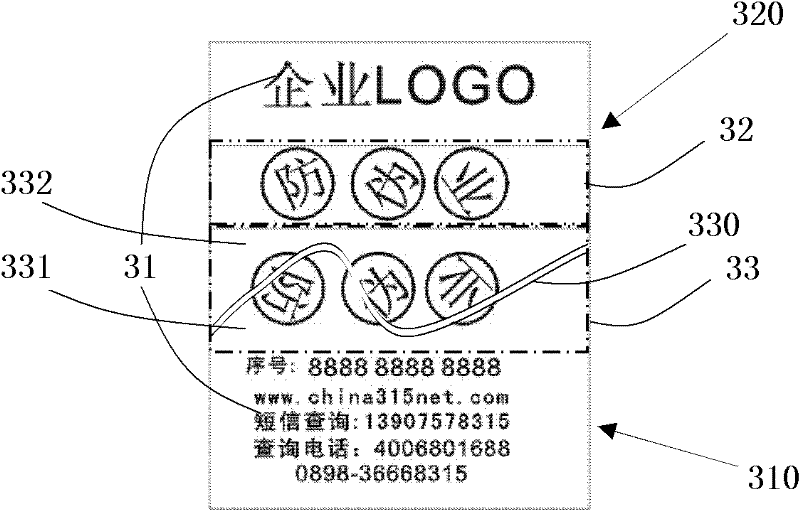

[0024] In a specific embodiment of the present invention, the text anti-counterfeiting bronzing film is a random cut type text anti-counterfeiting bronzing film, the text information layer also includes a random cutting area, the basi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com