Composite material and preparation process thereof

A composite material and preparation technology, applied in lamination devices, lamination, layered products, etc., can solve the problems of unfavorable liquid longitudinal diffusion and easy residual liquid, so as to avoid chemical pollution, good liquid absorption and permeability, and good The effect of the vertical diffusion function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

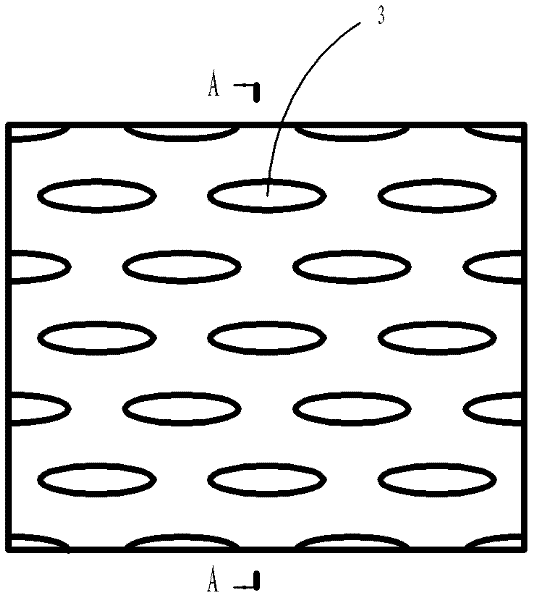

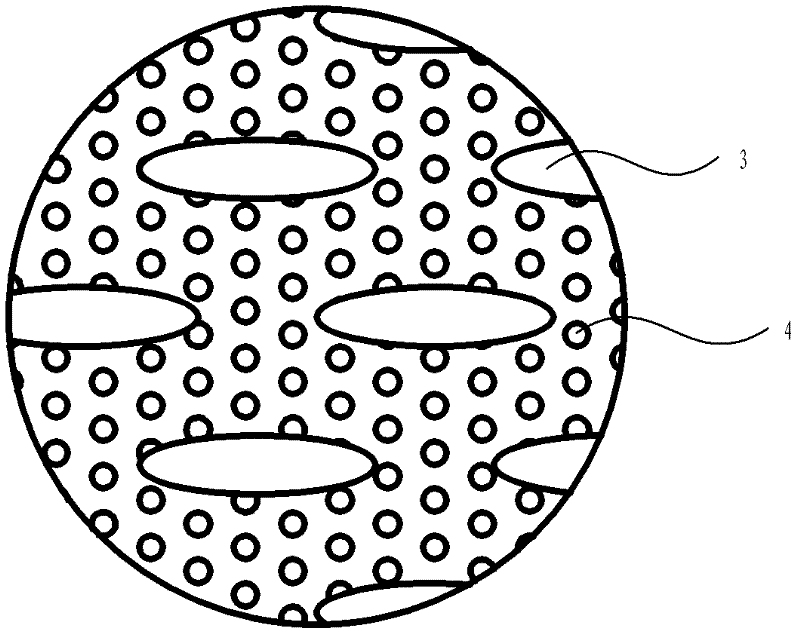

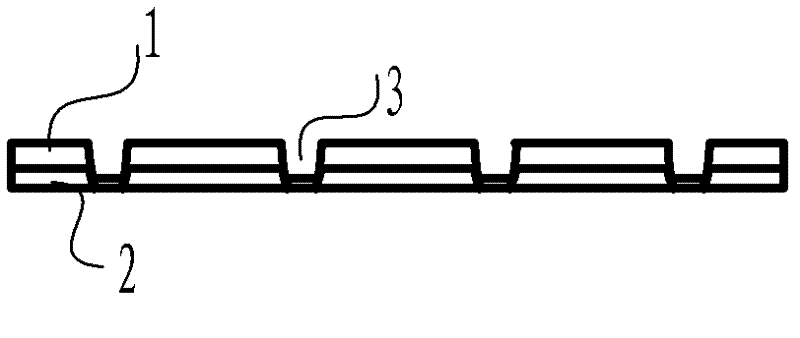

[0026] Such as Figure 1-3 As shown, a kind of composite material, comprises the upper stratum perforated film 1 that contacts with user's skin and the lower non-woven fabric 2 that is positioned at the lower side of described upper perforated film, the film surface of perforated film 1 is evenly distributed with through The pores 4 are vacuum-adsorbed and punched, and the opening area of a single pore 4 is about 0.04mm 2 , the opening density is 240 holes / cm 2 ;The basis weight of non-woven fabric 2 is 11g / m 2 . The upper layer of perforated film 1 and the lower layer of non-woven fabric 2 are composited together through the melting and pressing point 3. The melting and pressing point is in the shape of rice grains as shown in the figure. ), the area of a single fusion bonding point 3 of the composite material is about 0.4mm 2 , the density of the pressing point is 20 / cm 2 ; The pores of the perforated film 1 in the composite material are less than those in other are...

Embodiment 2

[0030] Such as image 3 As shown, first, the hot-melt resin raw material is extruded through the casting machine 5 at high temperature. The hot-melt resin raw material includes at least one of HDPE, LDPE, LLDPE, and MDPE. Proportional mixing The casting film 6 in a high-temperature molten state flows out from the die of the casting machine 5, and then rolls and passes through the surface with a uniform hole area of 0.06mm 2 The drum-type perforated mesh cage 7 of the small mesh model is equipped with a vacuum nozzle inside the roller perforated mesh cage 7 to generate high-strength negative pressure from the inside to the small mesh model, forcing the cast film 6 to rupture and form a small mesh. The hole shape corresponding to the hole model, the hole density is 240 holes / cm 2 , to form a perforated film, and at the same time, the suction action causes the perforated film to be rapidly cooled to a solid state in an instant, and the thickness is measured, pulled, and flattene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com