Automatic feeder of surface grinder

An automatic feeding, surface grinding machine technology, applied in the direction of grinding drive devices, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of low reliability, large noise and vibration, commutation failure, etc. Guaranteed smoothness and accuracy, noise and vibration suppression, vibration and noise suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

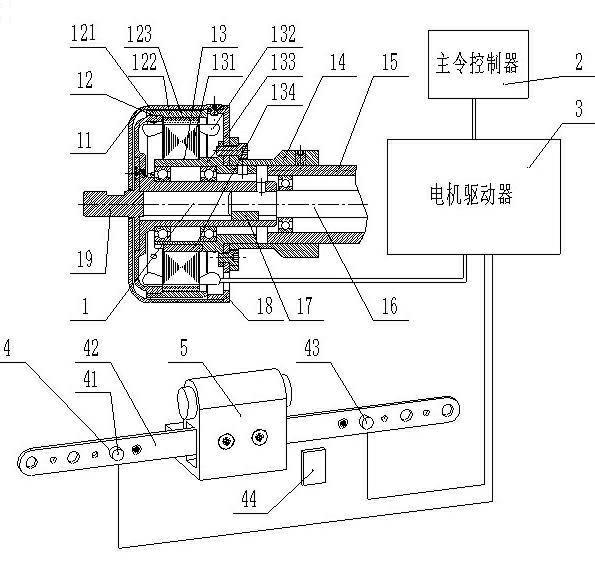

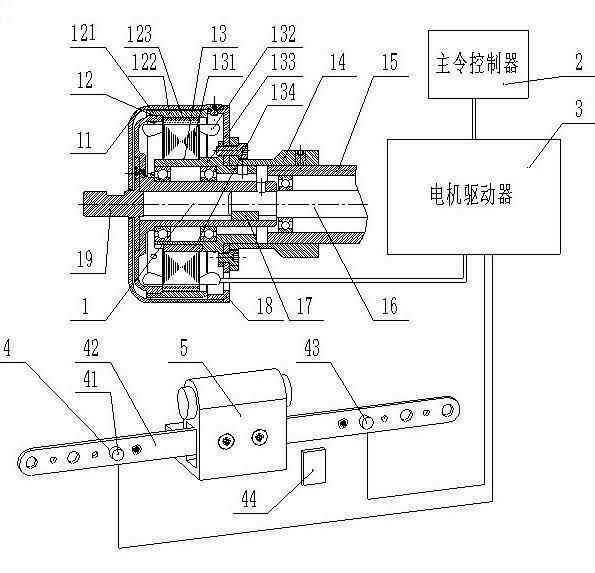

[0016] From figure 1 It can be seen from the figure that an automatic feeder for a surface grinder is composed of a brushless DC motor 1, a master controller 2, a motor driver 3 and a stroke module 4, and the motor driver 3 is connected to the motor 1 and the master through cables. The controller 2 and the stroke module 4 are connected.

[0017] The brushless DC motor 1 is fixed on the drive shaft sleeve 15 of the grinder, and the inner sleeve of the cup-shaped rotor 12 is directly sleeved on the drive shaft 16 and connected by a flat key 17 . The brushless DC motor 1 includes an organic casing 11 , a cup-shaped rotor 12 , a stator 13 , a connecting sleeve 14 , a front cover 18 , and an external shaft 21 . The stator 13 is composed of a stator core 131, a three-phase stator winding and a sensor 132, a stator cover 133 and a flat key 134, and a three-phase stator winding and a position sensor 132 are placed in the slot of the stator core 131. The inner ring is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com