Method and device for compensating indexing error of machine tool

A technology of indexing error and compensation device, applied in the field of error compensation, can solve the problems of 4 indexing error of turntable, influence of radial and axial motion error of rotating shaft, etc. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

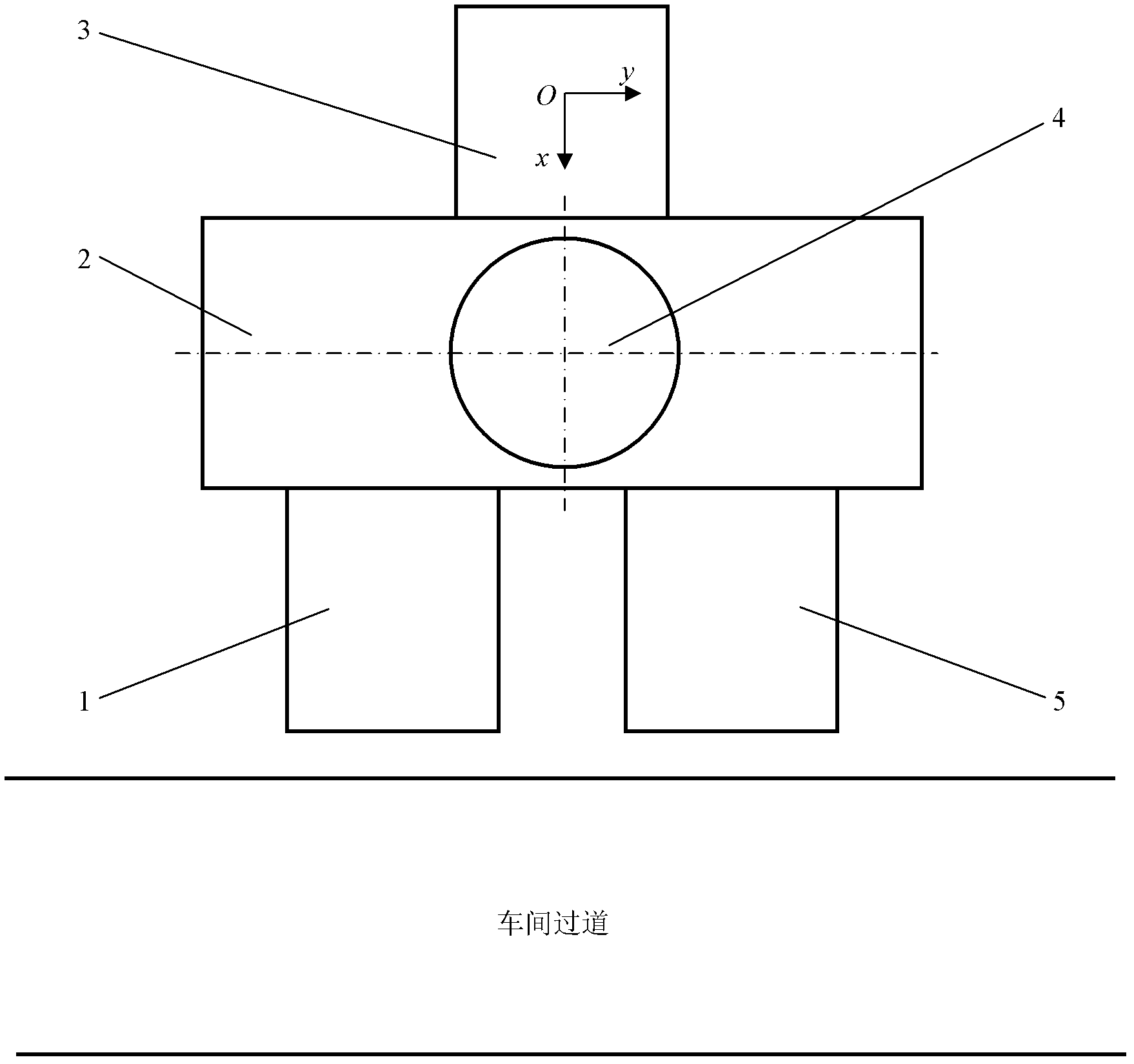

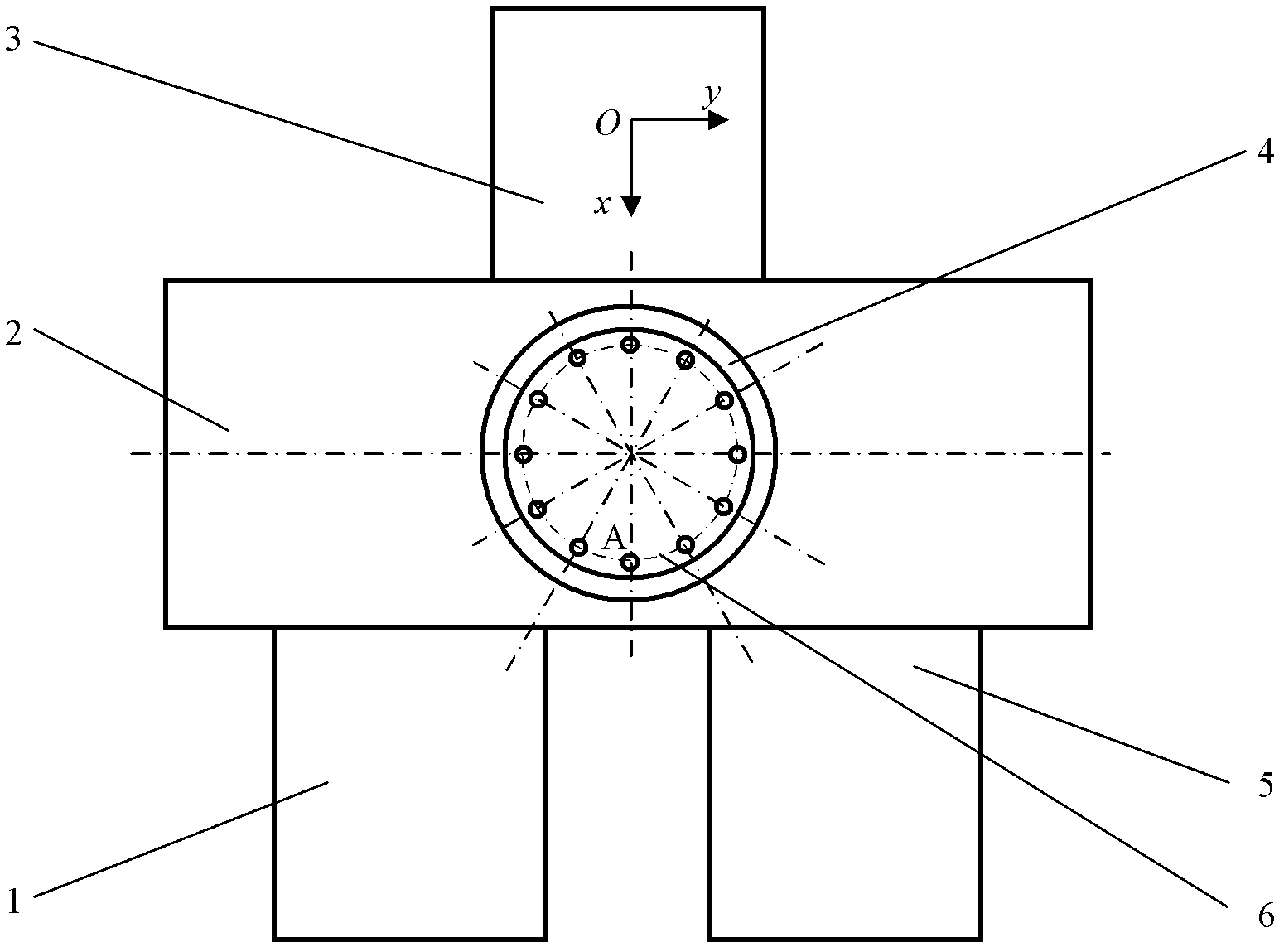

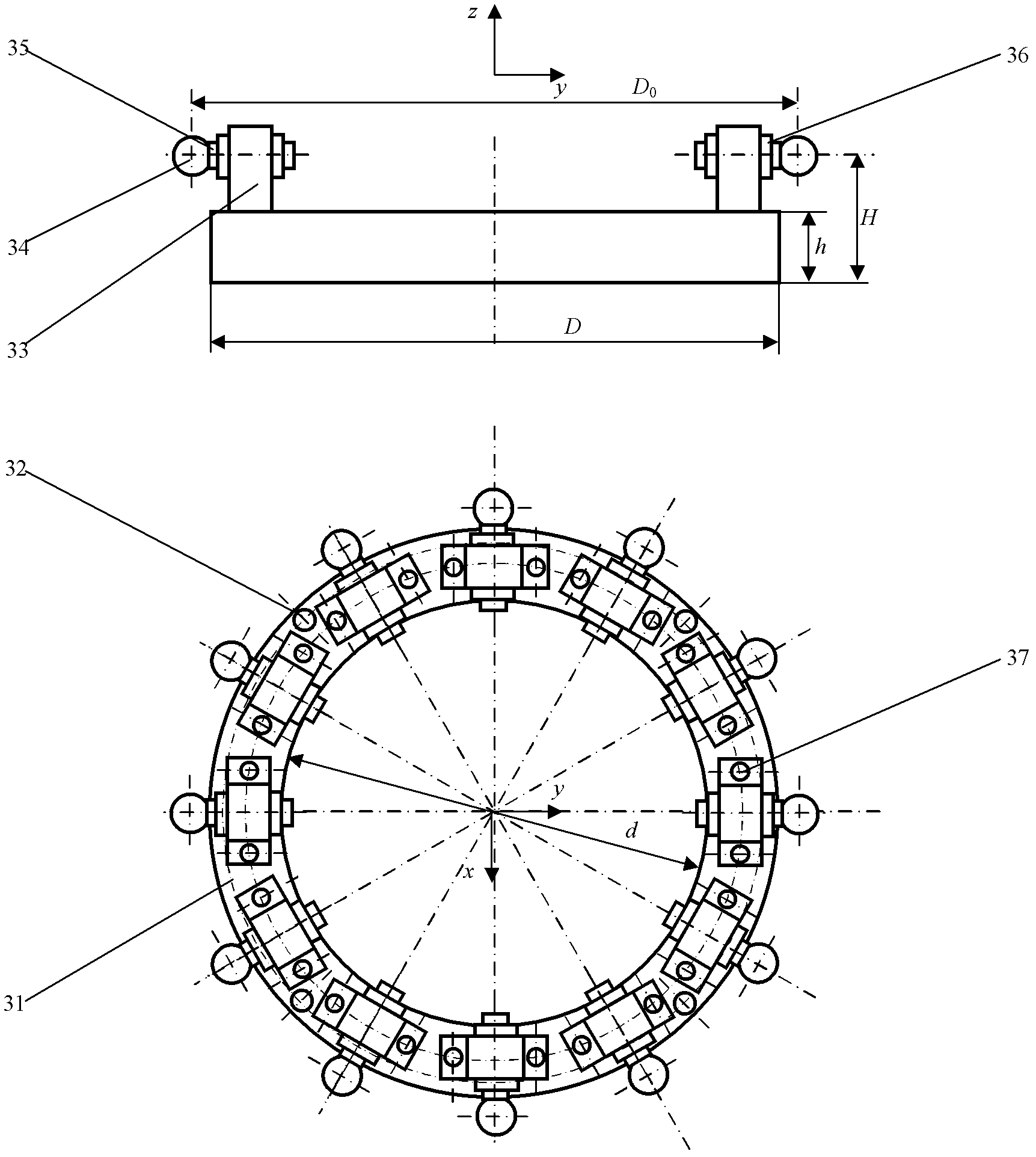

[0034] It is often difficult for the online in-situ measurement system of the geometric parameters of some complex workpieces to measure the entire workpiece. It is necessary to use the turntable of the machine tool to turn the part to be measured to the front of the measuring machine. The invention compensates the indexing error of the machine tool turntable and the radial and axial motion errors of the rotating shaft by detecting the change of the center position of one or several balls on the standard ball disc installed on the machine tool turntable, so that the error of the machine tool turntable can be compared to the measurement The result has no effect, improving the measurement accuracy. The invention belongs to the field of testing technology and instruments. Specifically, it involves on-line measurement and error compensation technology.

[0035] The invention provides a technology capable of compensating the indexing error of the machine tool turntable and the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com