Gantry-travelling drive mechanism

A technology of driving mechanism and gantry, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problem of insufficient rolling moment of the reducer, and achieve the effect of easy assembly, high transmission precision and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

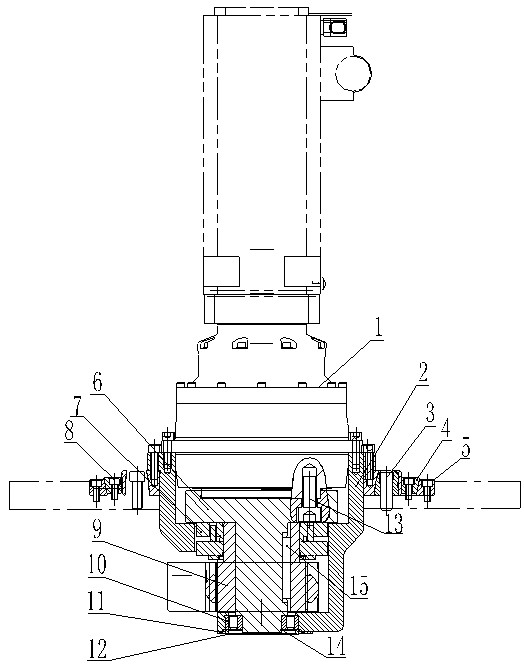

[0024] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments. The specific embodiments described here are only used to explain the present invention, and not used to limit the protection scope of the present invention.

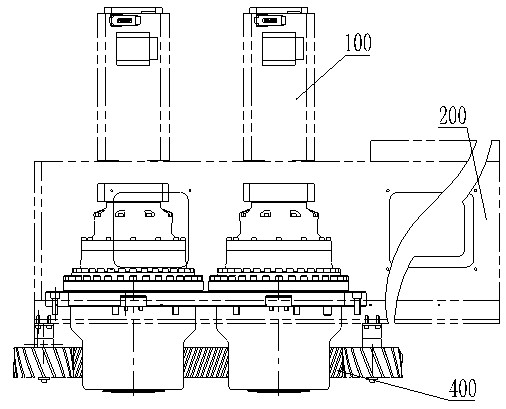

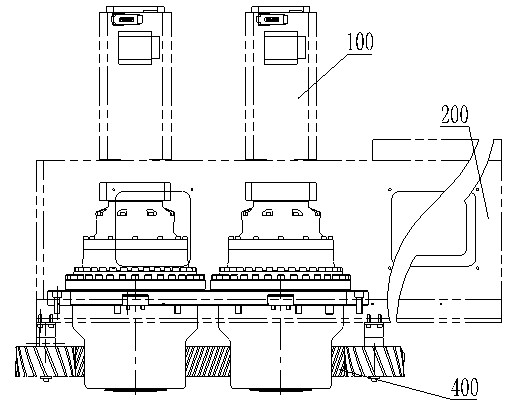

[0025] Combined reference figure 1 with figure 2 , In the gantry moving drive mechanism of the present invention, two servo motors 100 are each connected to a deceleration mechanism (see figure 2 ), each deceleration mechanism includes:

[0026] The transition support sleeve 2 fixed on the sliding seat 200 has one end sealed and the other end open;

[0027] Reducer 1, one end is connected to the servo motor 100, and the other end is connected to a transition shaft 6, the transition shaft 6 is arranged in the transition support sleeve 2;

[0028] Gear 9 is fixed on the transition shaft 6;

[0029] A number of cylindrical roller bearings 10 are arranged between the gear 9 and the transition suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com