Water-soluble nano-copper and preparation method thereof

A nano-copper, water-soluble technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of difficulty in exerting lubricating and catalytic properties, easy to produce precipitation, short stabilization time, etc. The effect of high yield, low production cost and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

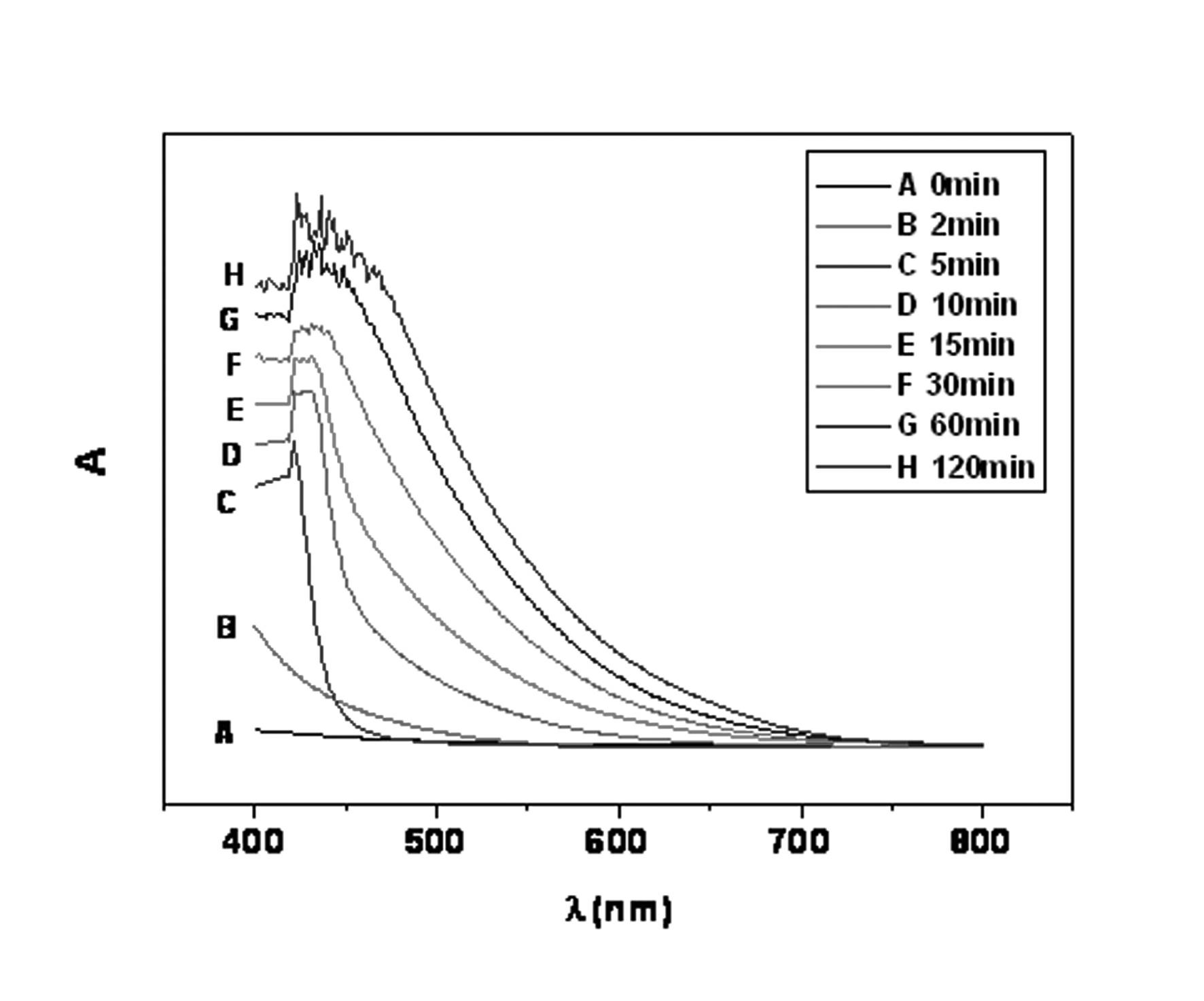

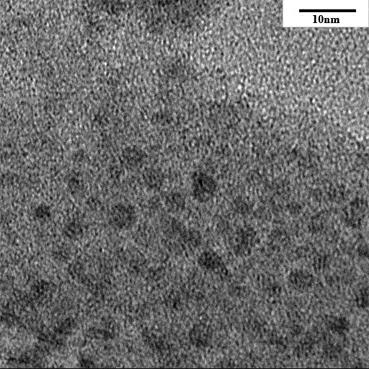

[0033] To 80 mL of distilled water, sequentially add 15 mL of NH 3 ·H 2 O, 0.016 mol mercaptoacetic acid, 5 mL 80% (mass concentration, the same below) hydrazine hydrate, and then transfer it to a 500 mL three-necked flask, and stir until completely dissolved. At this time, the solution is colorless and transparent, and recorded as system Ⅰ ; 0.032 mol CuSO 4 ·5H 2 Put O into a beaker, add 100 mL of distilled water to dissolve completely, the solution is blue, and record it as system II; slowly add II dropwise to the above mixed solution of I, and fully react at a constant temperature of 80°C for 1 h, and finally obtain a dark reddish-brown Nano-copper hydrosol, the nano-copper hydrosol can be stably dispersed in water for a long time without aggregation.

Embodiment 2

[0035] To 85 mL of distilled water, sequentially add 15 mL of NH 3 ·H 2 O, 0.016mol thioglycolic acid, 0.6048 g (0.016mol) NaBH 4 , and then transferred it to a 500 mL three-necked flask, and stirred until it was completely dissolved. At this time, the solution was colorless and transparent, which was recorded as System I; 0.032 mol Cu(NO 3 ) 2 ·3H 2 Put O into a beaker, add 100 mL of distilled water to dissolve completely, the solution is blue, and record it as system II; slowly add II dropwise to the above mixed solution of I, and fully react at a constant temperature of 60°C for 2 hours, and finally obtain a dark reddish-brown nano Copper hydrosol, the nano-copper hydrosol can be stably dispersed in water for a long time without aggregation.

Embodiment 3

[0037] To 80 mL of distilled water, sequentially add 15 mL of NH 3 ·H 2 O, 0.016 mol mercaptoacetic acid, 5 mL 80% hydrazine hydrate, and then transferred to a 500 mL three-necked flask, stirred until completely dissolved, at this time the solution was colorless and transparent, recorded as system Ⅰ; 0.032 mol Cu(OH ) 2 Put it into a beaker, add 100 mL of distilled water to completely disperse, the system is blue, and record it as system II; slowly add II to the above mixed solution of I, and fully react at a constant temperature of 40°C for 2 h, and finally obtain a dark reddish-brown nano Copper hydrosol, the nano-copper hydrosol can be stably dispersed in water for a long time without aggregation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com