Co-rotating type cooling drum

A cooling drum and co-rotating technology, which is applied in casting molding equipment, cleaning/processing machinery of casting mold materials, metal processing equipment, etc., can solve the difficulty of replacing and maintaining the spiral sheet 5, small heat exchange area, and slow heat exchange speed and other problems, to achieve the effect of long service life, large area and fast cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

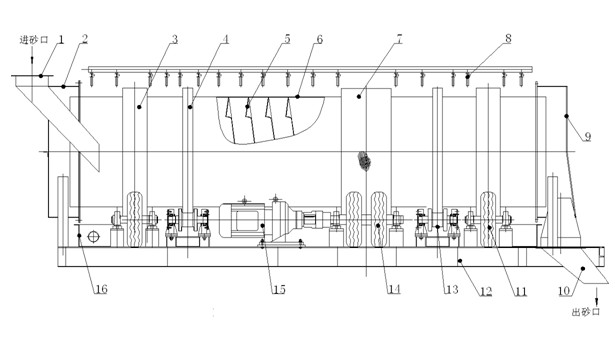

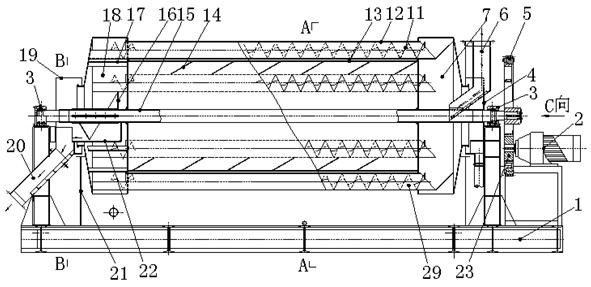

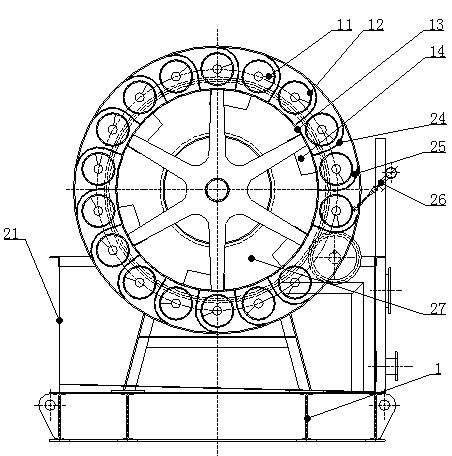

[0024] A co-rotating cooling drum, which consists of three parts: a power transmission system installed on the base 1, a drum driven by the power transmission system, and a cooling device. The two ends of the rotating drum are respectively connected with a feeding device and a discharging device . The power transmission system includes a reduction motor 2 erected on the base 1. The reduction motor 2 transmits torque through the driving gear 23 and the driven gear 5 of the meshing transmission to the shaft 15 supported by the bearing 3 at both ends and passing through the inside of the drum. 15 drives the drum to work. The drum includes a horizontally installed inner cylinder 13, several outer cylinders 12 surrounding the outer periphery of the inner cylinder 13, and a sand inlet chamber 7 and a sand outlet chamber 18 respectively connected to the feeding device and the discharging device. The junction between 13 and shaft 15 is a fixed and sealed connection, and the joints be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com