Preparation method for dodecyl trimethyl ammonium bromide (DTAB) antibacterial solid paraffin

A technology of dodecyltrimethylammonium bromide and solid paraffin, applied in botany equipment and methods, chemicals for biological control, animal repellants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0153] Example 1: A preparation method of dodecyltrimethylammonium bromide antibacterial paraffin wax (No. 50)

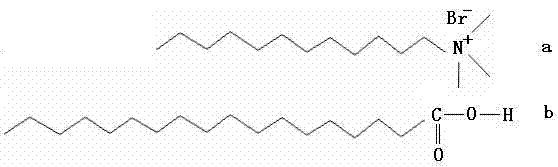

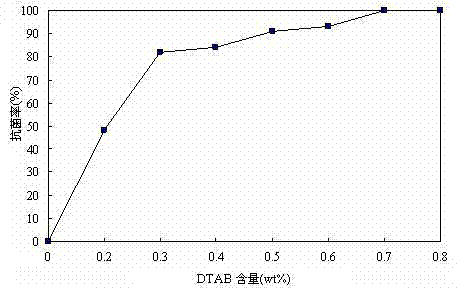

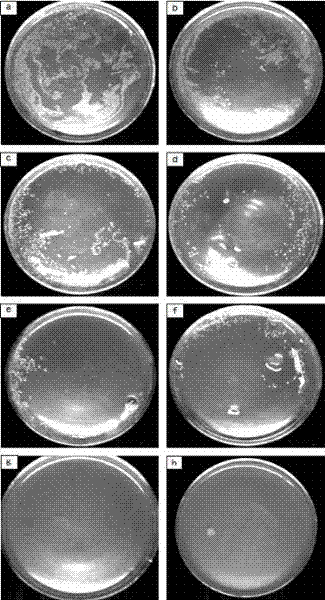

[0154] In this example, No. 50 solid paraffin is used as raw material, dodecyltrimethylammonium bromide (DTAB) is used as antibacterial agent, stearic acid is used as DTAB dispersion modifier, and a two-step mixing method of low temperature and high temperature is adopted. DTAB is evenly dispersed in solid paraffin to prepare a DTAB antibacterial solid paraffin (No. 50) with excellent antibacterial properties, and its preparation process is carried out according to the following 8 steps:

[0155] (1) Paraffin wax melting: Weigh a certain amount of solid paraffin and place it in a beaker. Use a universal electric furnace to slowly heat the solid paraffin until it melts, and finally effectively control and stabilize the melt temperature at 80-90°C. ;

[0156] (2) Weighing of stearic acid: according to the ratio of DTAB: stearic acid = 1:5-10, weigh ...

example 2

[0164] Example 2: a preparation method of dodecyltrimethylammonium bromide antibacterial paraffin wax (No. 52)

[0165] In this example, No. 52 paraffin wax is used as the raw material, and other reagents and preparation steps are exactly the same as those in Example 1.

[0166]

example 3

[0167] Example 3: A preparation method of dodecyltrimethylammonium bromide antibacterial paraffin wax (No. 54)

[0168] In this example, No. 54 solid paraffin is used as the raw material, and other reagents and preparation process steps are exactly the same as those in Example 1.

[0169]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com