Hybrid seed production efficient pollination machine

A technology of hybrid seed production and pollination machine, which is applied in the fields of botany equipment and methods, applications, plant gene improvement, etc., can solve the problems of hindering pollen from entering the panicle layer, limited pollen flying distance, and reduced pollen efficiency, so as to increase the number of parents. The yield, high pollen utilization rate, and the effect of increasing seed setting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

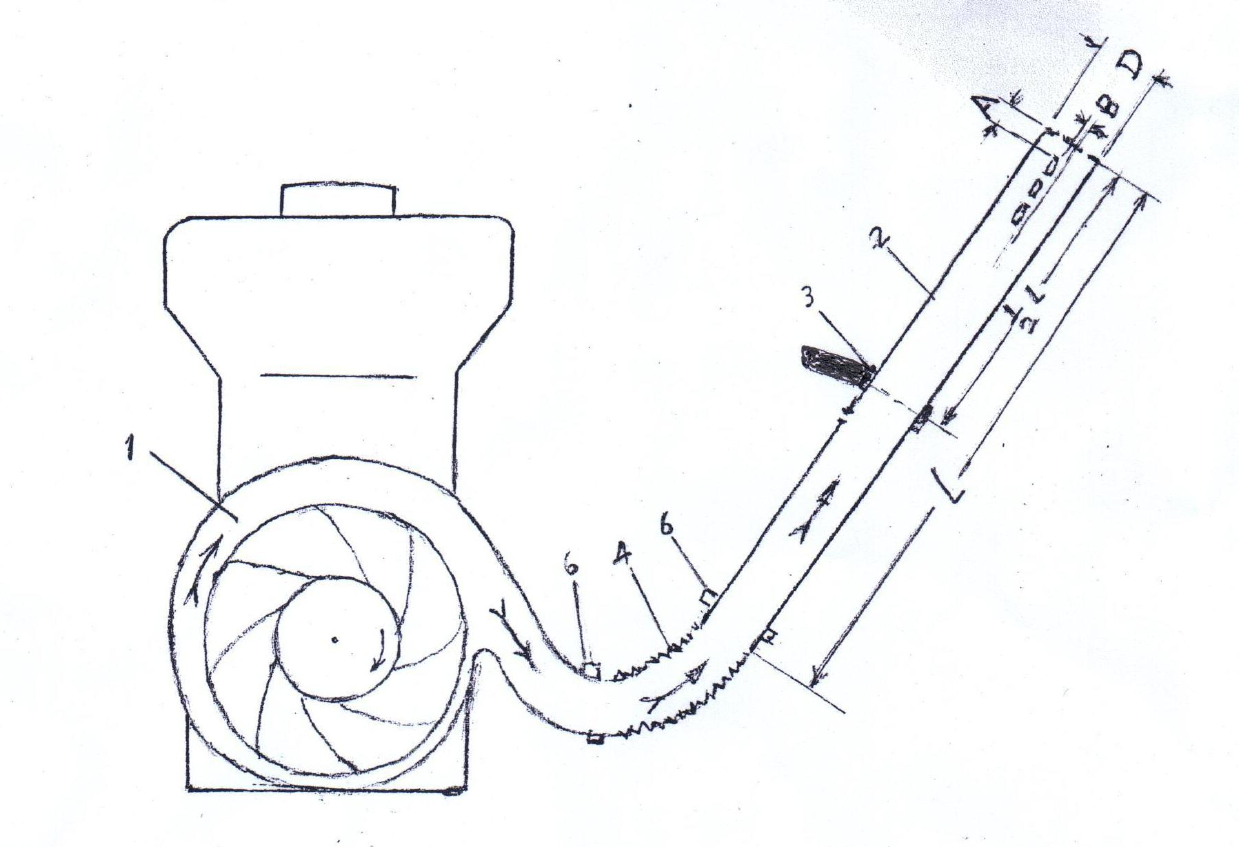

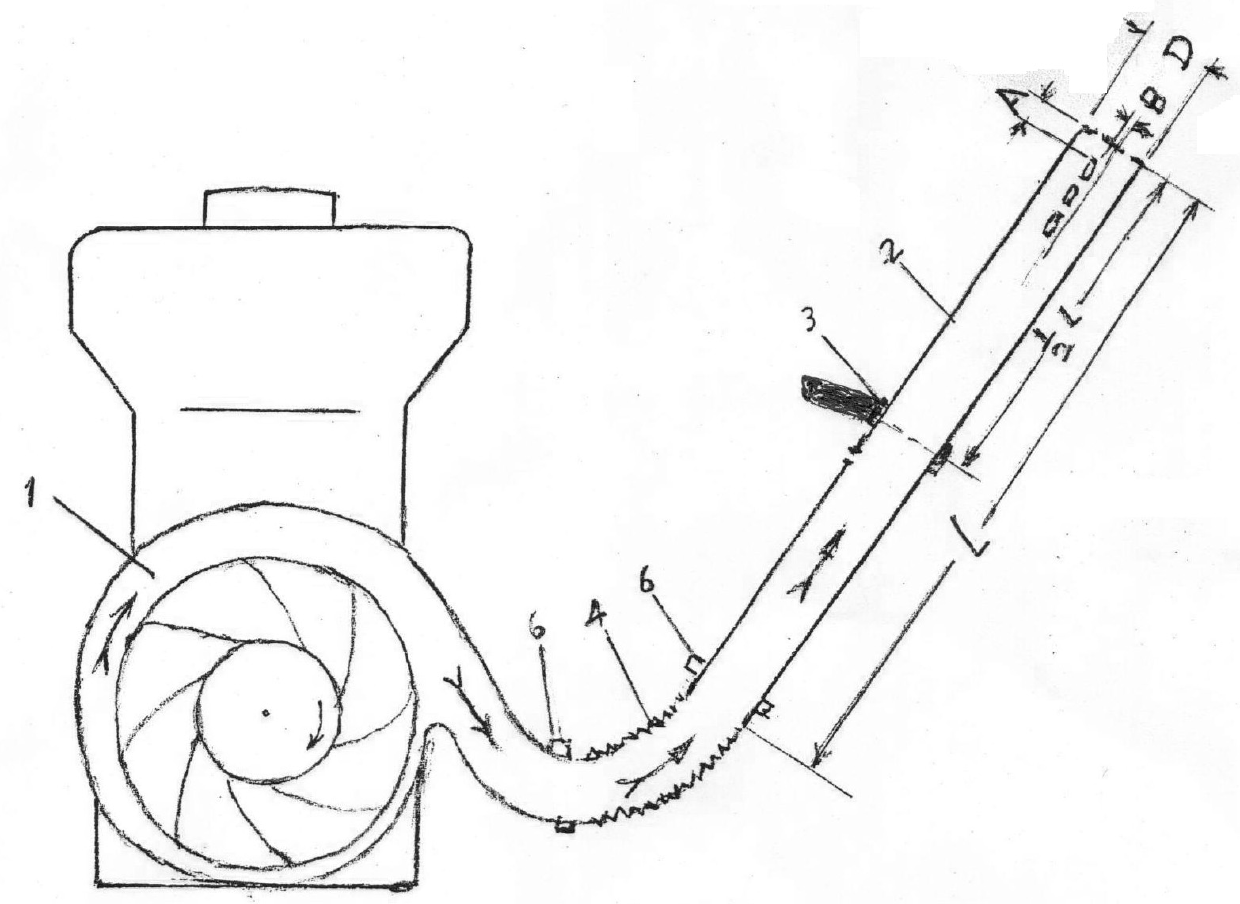

[0015] The structure of the present invention is attached figure 1 As shown, fan 1 in the figure is a commercially available product, which can be replaced by a commercially available motor sprayer. Air duct 2 is made of light metal or engineering plastics pipe. The present invention adopts plastic pipe to make, and wherein length L is the PVC pipe of 1000mm, diameter D is 80mm, wall thickness is 1.5mm. The air inlet end of the air duct 2 and the serpentine hose 4 are fastened with a hoop 6, and the air outlet end is tightly closed with a sealing cover 5, and the sealing cover 5 is 5 mm away from the center point horizontally on both sides to both sides for air outlet. Holes for blowing to both sides when blowing. On the L point of the air duct 2, there is a directional rope 3 made of a cotton braid that is hung on the operator's shoulder when the firm Velcro is used for pollination. Simultaneously supply 1 piece of 5mm oblique holes for upper body blowing when the operator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com