Hydrocarbon synthesis reaction apparatus, hydrocarbon synthesis reaction system, and hydrocarbon synthesis reaction method

一种反应装置、烃合成的技术,应用在烃合成反应装置领域,能够解决催化剂劣化、烃合成成品率下降、催化剂粒子堵塞等问题,达到抑制劣化、提高成品率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

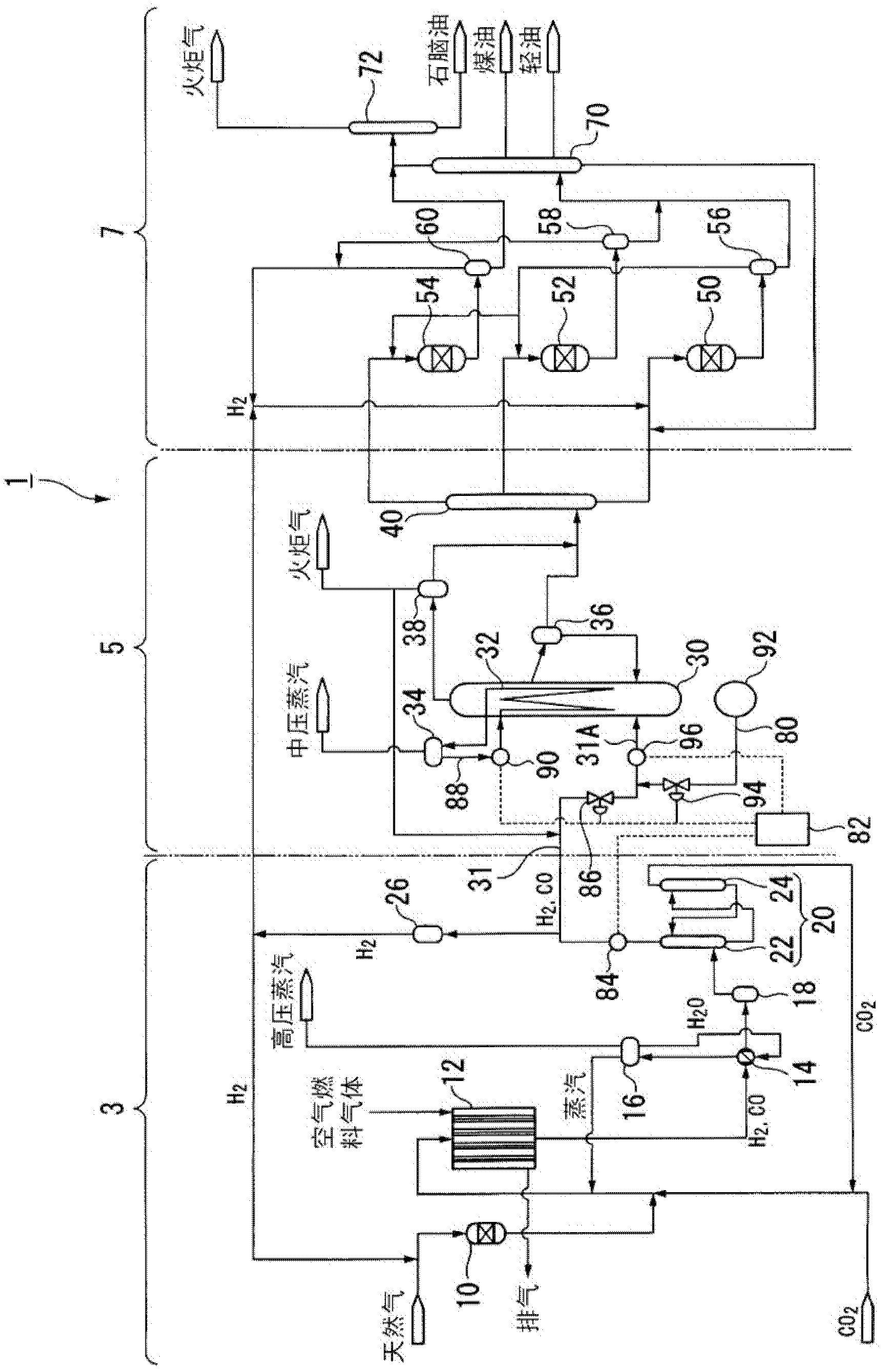

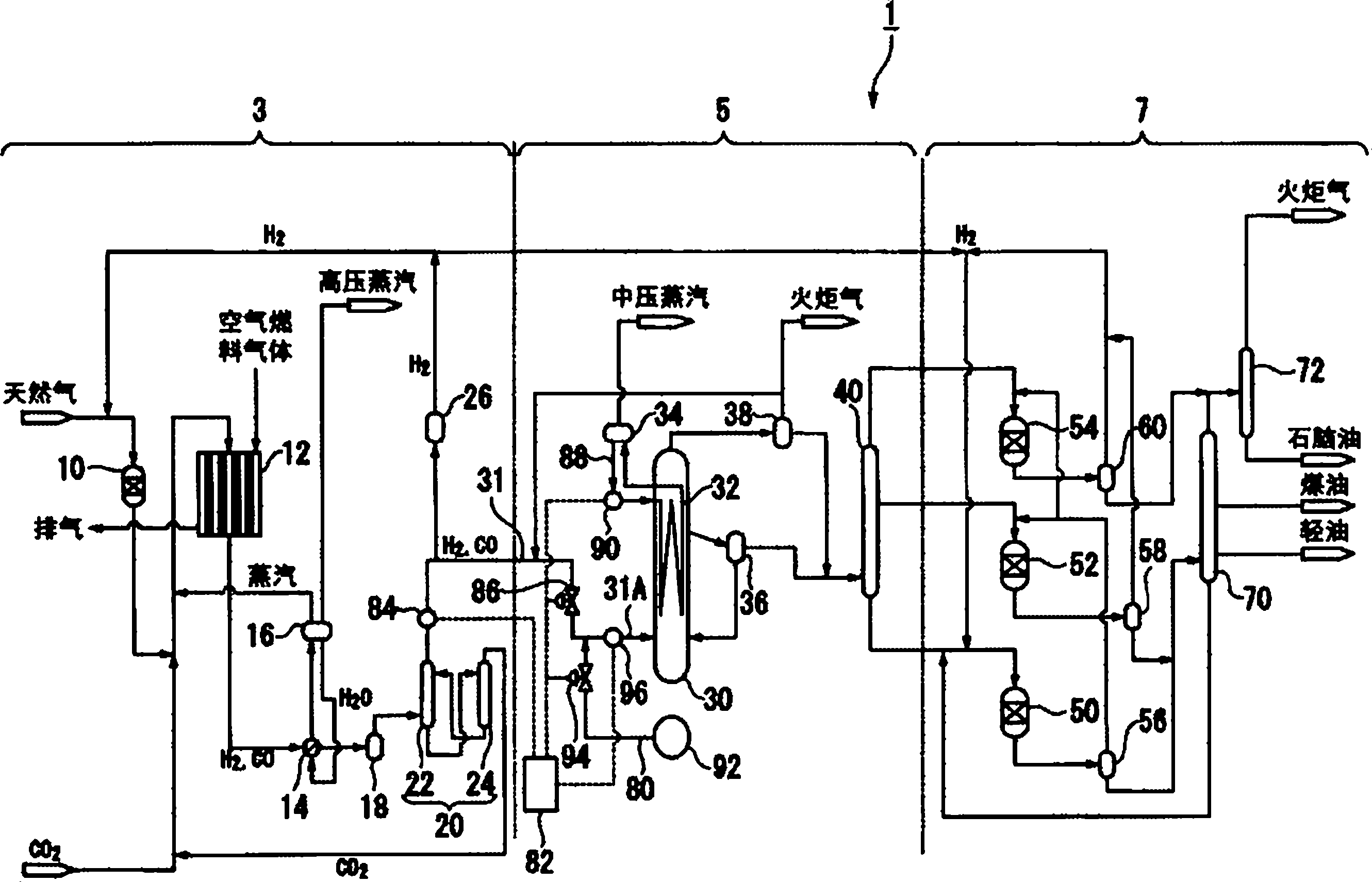

[0040] Below, refer to figure 1 A liquid fuel synthesis system according to an embodiment of the present invention will be described.

[0041] like figure 1 As shown, a liquid fuel synthesis system (hydrocarbon synthesis reaction system) 1 is a factory facility for performing a GTL process for converting hydrocarbon raw materials such as natural gas into liquid fuels. This liquid fuel synthesis system 1 is composed of a synthesis gas generation unit 3 , an FT synthesis unit (hydrocarbon synthesis reaction device) 5 , and a product refining unit 7 . The synthesis gas generation unit 3 is used to reform natural gas as a hydrocarbon feedstock to generate synthesis gas containing carbon monoxide gas and hydrogen gas. The FT synthesis unit 5 generates liquid hydrocarbons from the generated synthesis gas by using the FT synthesis reaction. The product refining unit 7 hydrogenates and fractionates liquid hydrocarbons produced by the FT synthesis reaction to produce base materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com