Corrosion-resisting motor rotor shaft

A technology of motor rotor shaft and motor rotor, which is applied to electric components, electrical components, electromechanical devices, etc., can solve the problems of reduced motor performance, inability to use, and not available, and achieves good corrosion resistance and improved service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

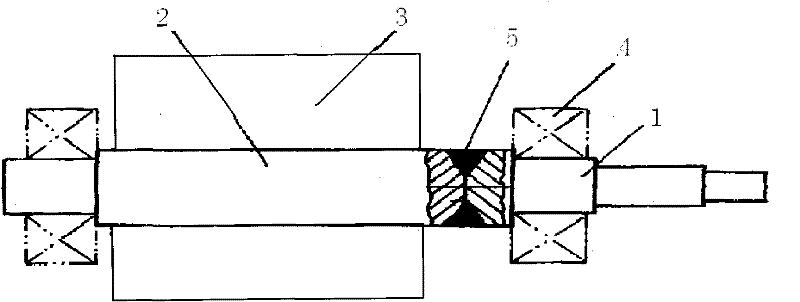

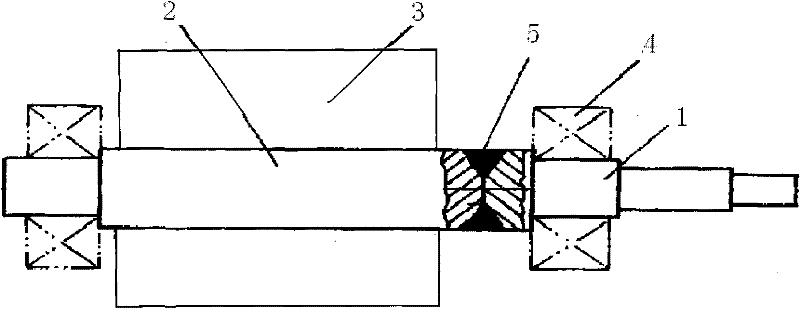

[0008] like figure 1 As shown, a corrosion-resistant motor rotor shaft is composed of a front shaft 1 and a rear shaft 2. The front shaft 1 is the shaft body at the front end of the motor rotor 3 and is made of stainless steel. Rear axle 2 is made of carbon steel, generally adopts No. 45 steel. The entire rotor shaft is welded by the front shaft 1 and the rear shaft 2. The welding seam 5 of the front shaft 1 and the rear shaft 2 can be between the motor rotor 3 and the front bearing 4, or at the front end of the front bearing 4. It can be no less than 10mm Place (as shown in Figure 2), specifically where is more suitable, depending on the size of the pump body, it is better to make the front axle 1 with the part in contact with the fluid. The chamfer of the welding seam 5 between the front axle 1 and the rear axle 2 is 7-170 degrees, generally 60-120 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com