Miniaturized S waveband micro-strip ferrite circulator

A ferrite and circulator technology, applied in the microwave field, can solve the problems of difficult adjustment of device frequency characteristics, lack of flexibility in impedance matching, large overall size, etc., and achieve the effect of compact structure, convenient design, and reduced overall length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and an embodiment, and it cannot be assumed that the embodiment of the present invention is limited thereto.

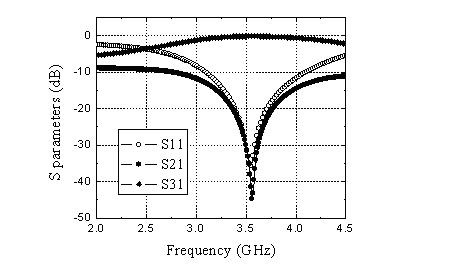

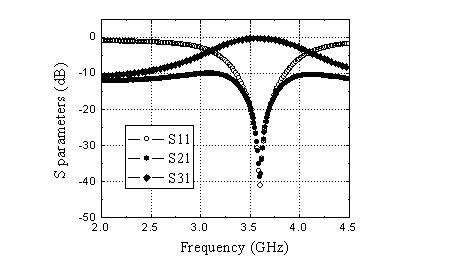

[0018] Such as Figure 3 to Figure 5 As shown, the embodiment of the present invention provides a miniaturized S-band microstrip ferrite circulator with a working center frequency of 3.55 GHz and a bandwidth of 200 MHz. The reflection and isolation at the center frequency are better than 35 dB, and the insertion loss is lower than 0.5 dB. , the standing wave ratio is less than 1.1. The circulator is manufactured using the currently mature microstrip film technology.

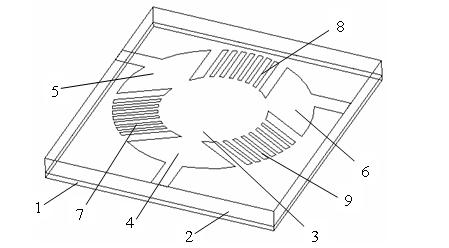

[0019] Such as figure 1 and figure 2 As shown, the present invention provides a miniaturized S-band microstrip ferrite circulator.

[0020] The saturation magnetization of the spun ferrite substrate 2 is 600Gs, the relative permittivity is 13.3, and the loss tangent is 2×10 -4 , and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com