Gas humidifying system for fuel cell testing platform

A test platform and fuel cell technology, applied in the directions of fuel cells, fuel cell additives, electrical components, etc., can solve the problems of unusable fuel cell test platforms, complex systems, and complex structures for fuel cell humidifiers, and achieve online The effect of the automatic replenishment function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

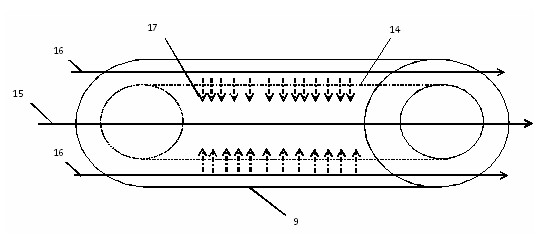

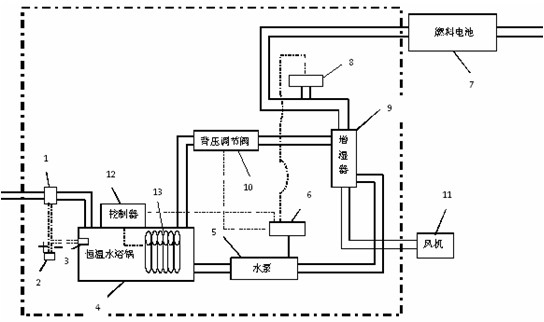

[0035] Such as figure 1 As shown, the multi-stage variable gas humidification system used for the fuel cell test platform, in which the constant temperature water bath 4, the heating rod 13 and the temperature controller 12 can perform multi-stage heating on the humidification water source entering the fuel cell, and the temperature range is 20 ℃-100℃; the water pump 5 and the back pressure regulating valve 10 that can adjust the water flow can realize the control of the water flow and pressure. The tube humidifier 9 is connected to the fuel cell module 6 in series, and the multi-stage heating and humidification flow control can be realized through the water conversion of the perfluorosulfonic acid membrane tube humidifier 9 .

[0036] figure 1 Medium temperature and high humidity temperature and humidity sensor 8 is installed between the fuel cell mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com