Lamination machine

A lamination machine and lamination technology, applied in electrode manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of high quality adjustment personnel, long debugging time, and inconvenient adjustment. , to shorten the changeover time, save manpower and costs, and facilitate debugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

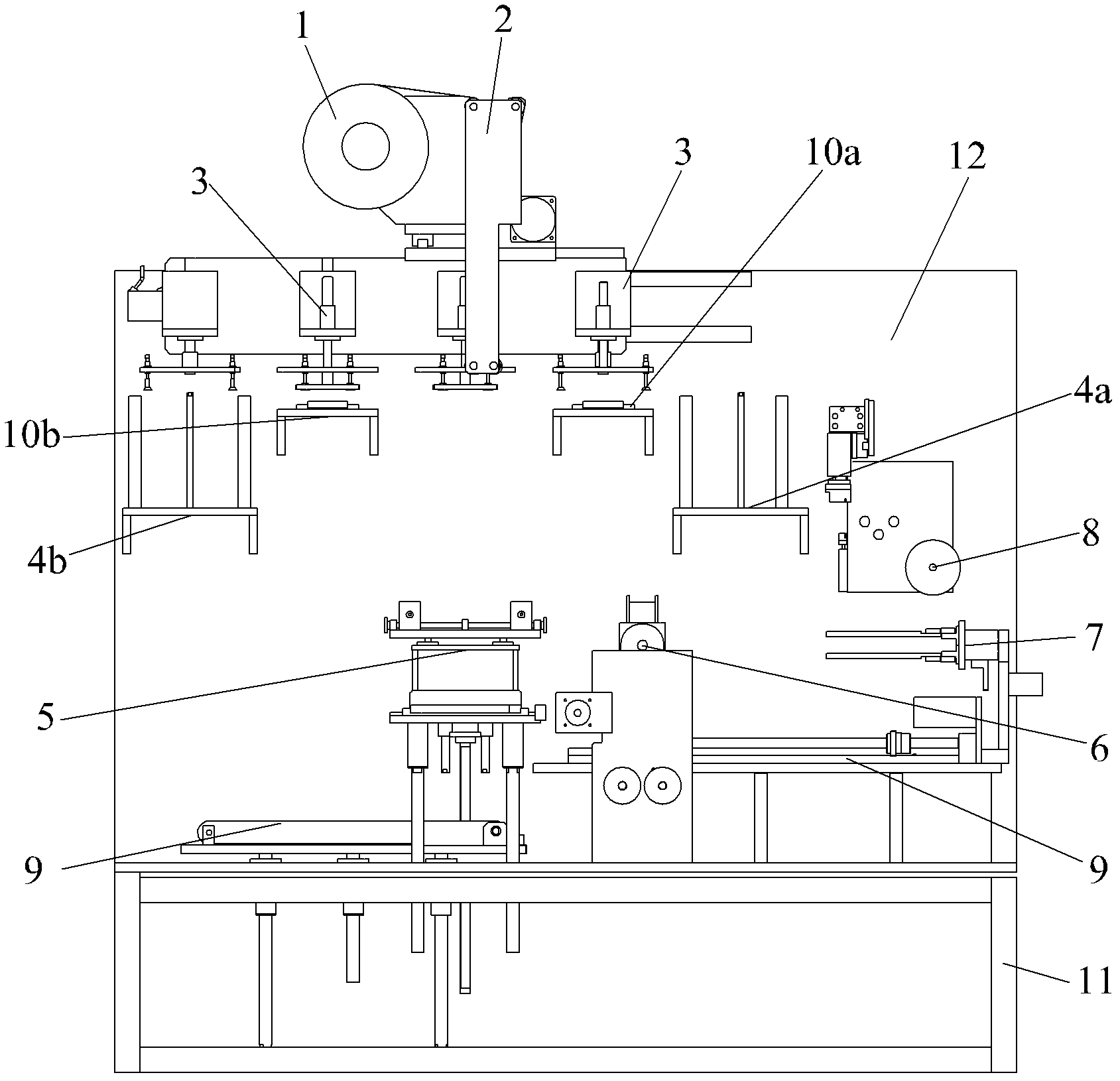

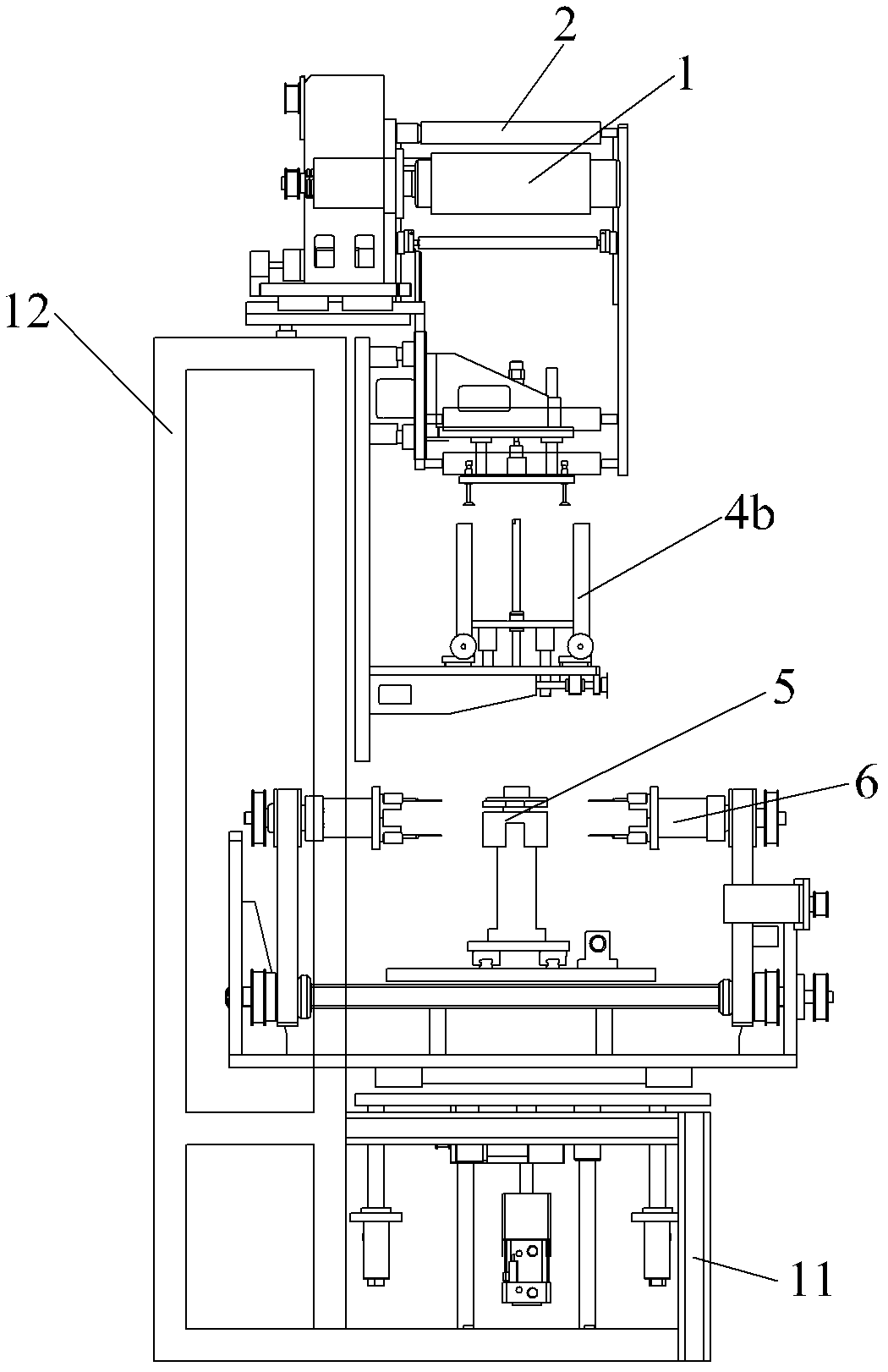

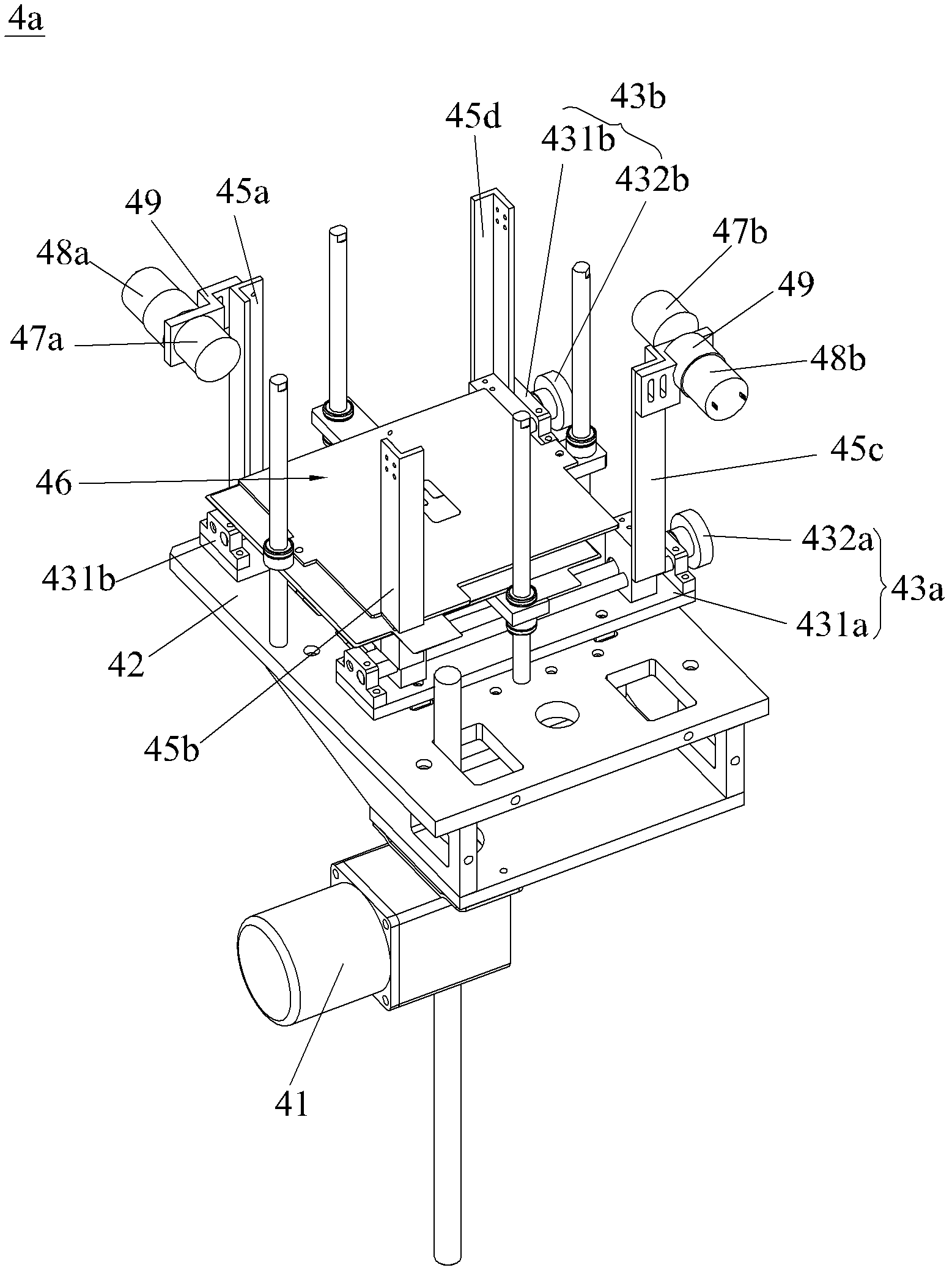

[0030] Such as figure 1 , figure 2 As shown, the lamination machine of the present invention includes a horizontally placed frame 11, on which a base plate 12 is vertically installed, and each working mechanism of the lamination machine is respectively installed on the base plate 12 and the frame 11. Specifically, the stacking machine includes a film releasing mechanism 1, a diaphragm tension edge correcting mechanism 2, two feeding mechanisms 3, a positive material box 4a, a negative material box 4b, a stacking mechanism 5, a winding mechanism 6, a material shifting mechanism 7, Gluing mechanism 8, discharge pull belt 9, positive electrode positioning mechanism 10a, negative electrode positioning mechanism 10b.

[0031] The film release mechanism 1 is installed on the top of the bottom plate 12, and the axial direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com