Charged coupled device module and method of manufacturing the same

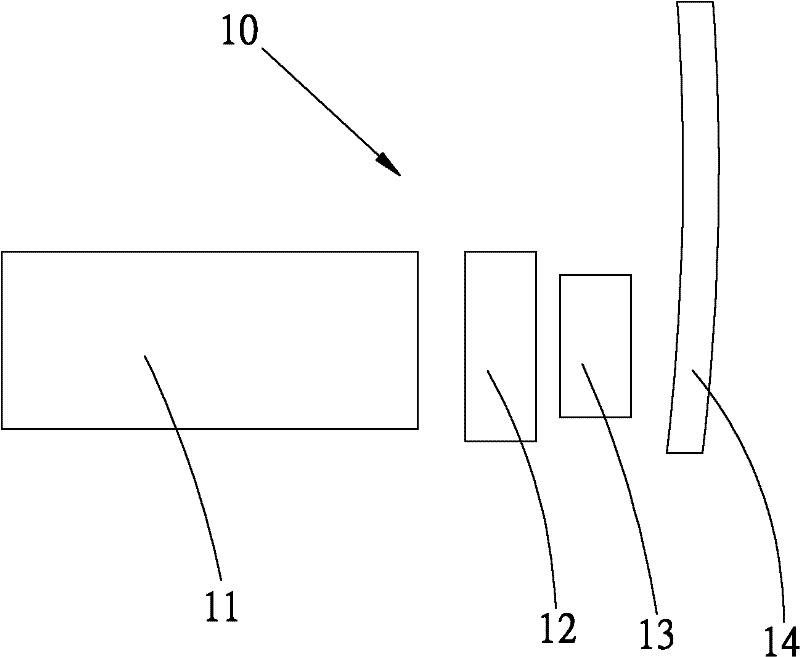

A manufacturing method and module technology, applied in the fields of printed circuit manufacturing, semiconductor/solid-state device manufacturing, radiation control devices, etc., capable of solving problems such as easy fracture, easy deformation of the main circuit board 14, and affecting electrical connection properties, etc. To achieve the effect of improving the pin breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

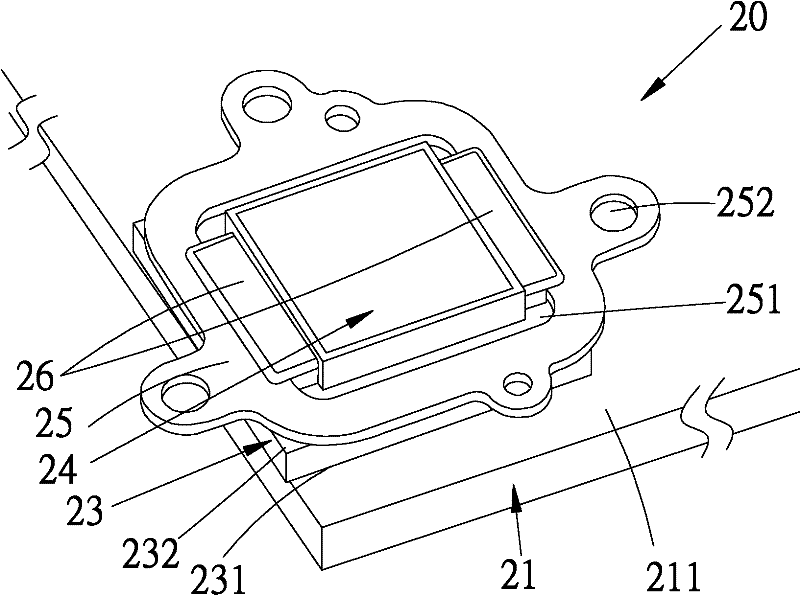

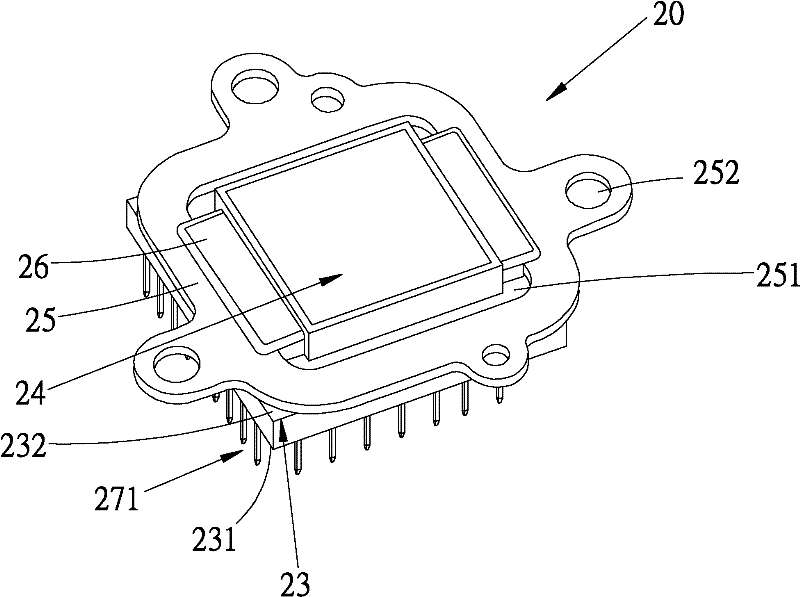

[0049] The CCD module and its manufacturing method of the present invention will be described below with reference to related drawings, wherein the same elements will be described with the same symbols. At the same time, the following diagrams are used to express schematic representations related to the features of the present invention. figure 2 It is a schematic diagram of the CCD module of the present invention. The CCD module 20 of the present invention is fixed between a lens assembly (not shown) and a main circuit board 21 , wherein the main circuit board 21 has a first board surface 211 .

[0050] And the CCD module 20 of the present invention includes a rigid circuit board 23 and a CCD element 24, wherein the rigid circuit board 23 has a first surface 231 and a second surface 232, and the first surface 231 of the rigid circuit board 23 is facing the main circuit The first board surface 211 of the board 21; and the CCD element 24 is disposed on the second surface 232 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com