Paper thickness detection device

A technology for thickness detection and paper, applied in the field of paper thickness detection devices, can solve the problems of violent movement of detection blocks, errors, and inability to detect thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The paper thickness detection device of the present invention will be described in detail based on the drawings.

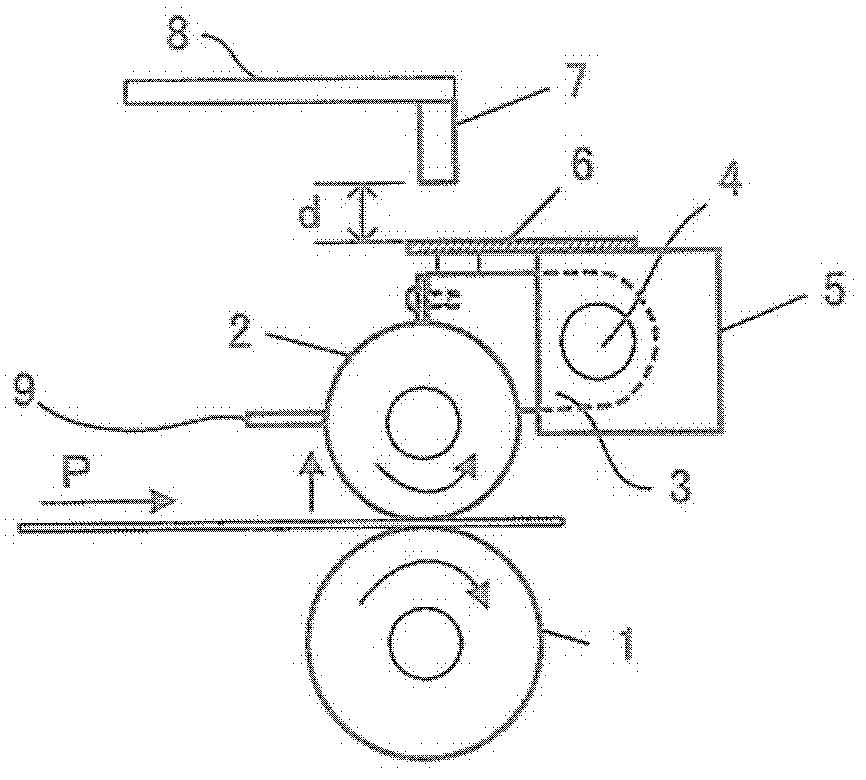

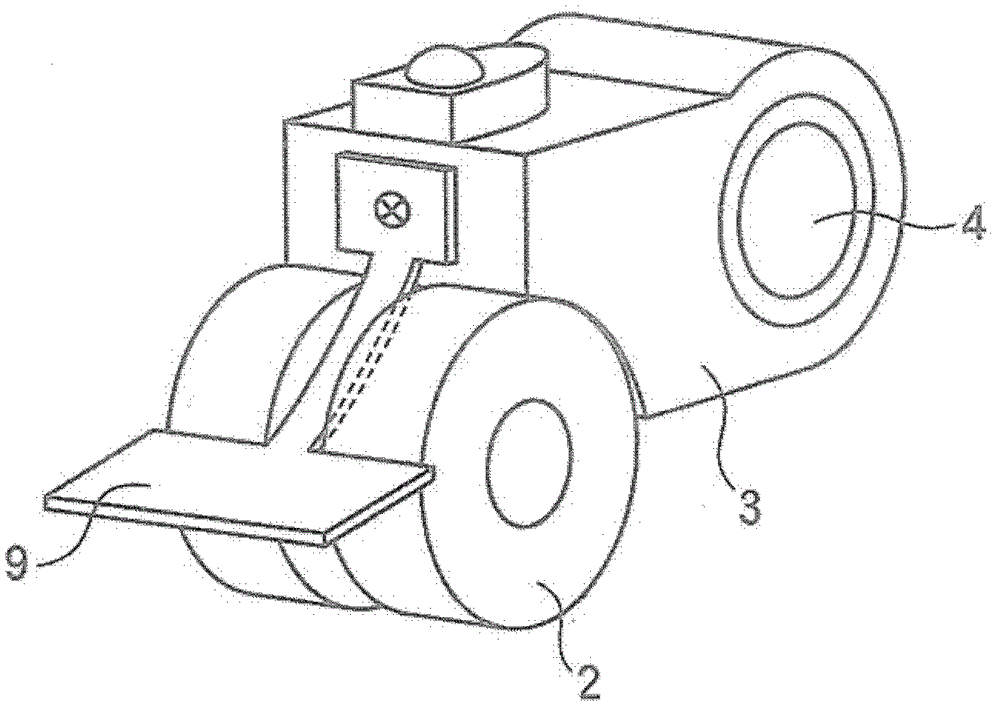

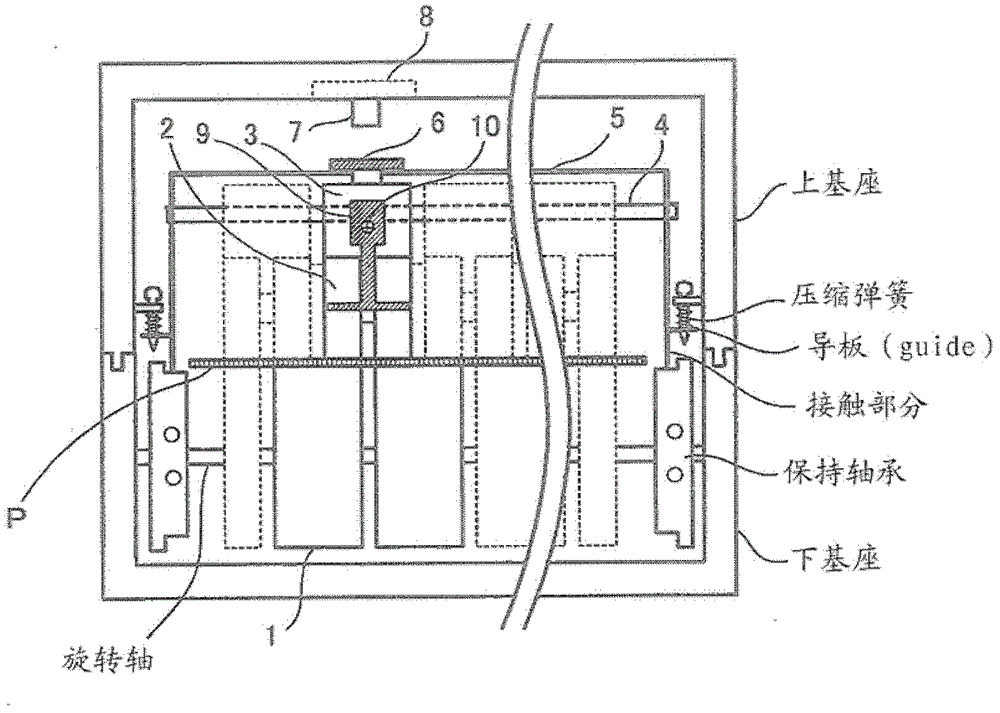

[0032] figure 1 It is a diagram for explaining the principle of thickness detection of the paper thickness detection device of the present invention, which includes: a reference roller 1, whose rotating shaft is fixed and used as a criterion for determining the thickness; a detection roller 2, which is set in contact with the reference roller 1; The block 3 is provided with a detection roller 2 at one end, and the other end is rotatably fixed around the support shaft 4, and moves in the direction of the arrow according to the thickness of the paper P passing between the reference roller 1 and the detection roller 2. Position; holding block 5, at least holding the support shaft 4 of the detection block 3; metal leaf spring 6, fixed on the holding block 5, pressing a part of the detection block 3 to maintain the tightness between the detection roller 2 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com