Tire vulcanizing production control system and operation adjusting method

A tire vulcanization and operation technology, which is applied in manufacturing computing systems, instruments, data processing applications, etc., can solve problems such as the inability to comprehensively balance process parameter constraints, achieve the elimination of subjective deviation and lack of experience, realize automatic management, and balance constraints Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

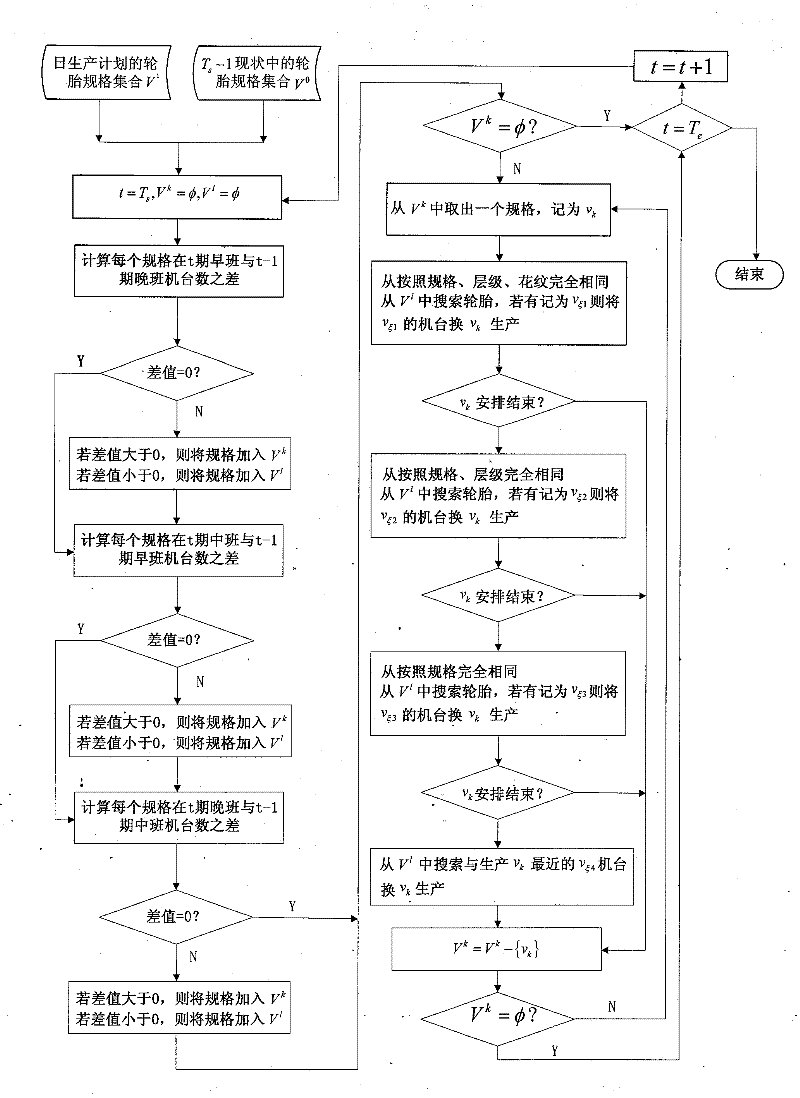

Method used

Image

Examples

Embodiment Construction

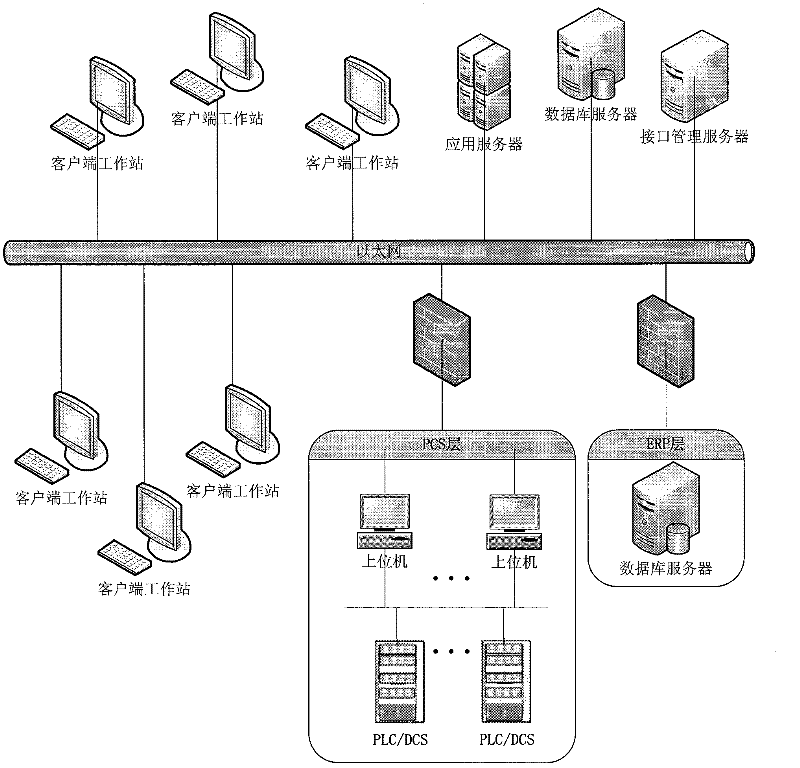

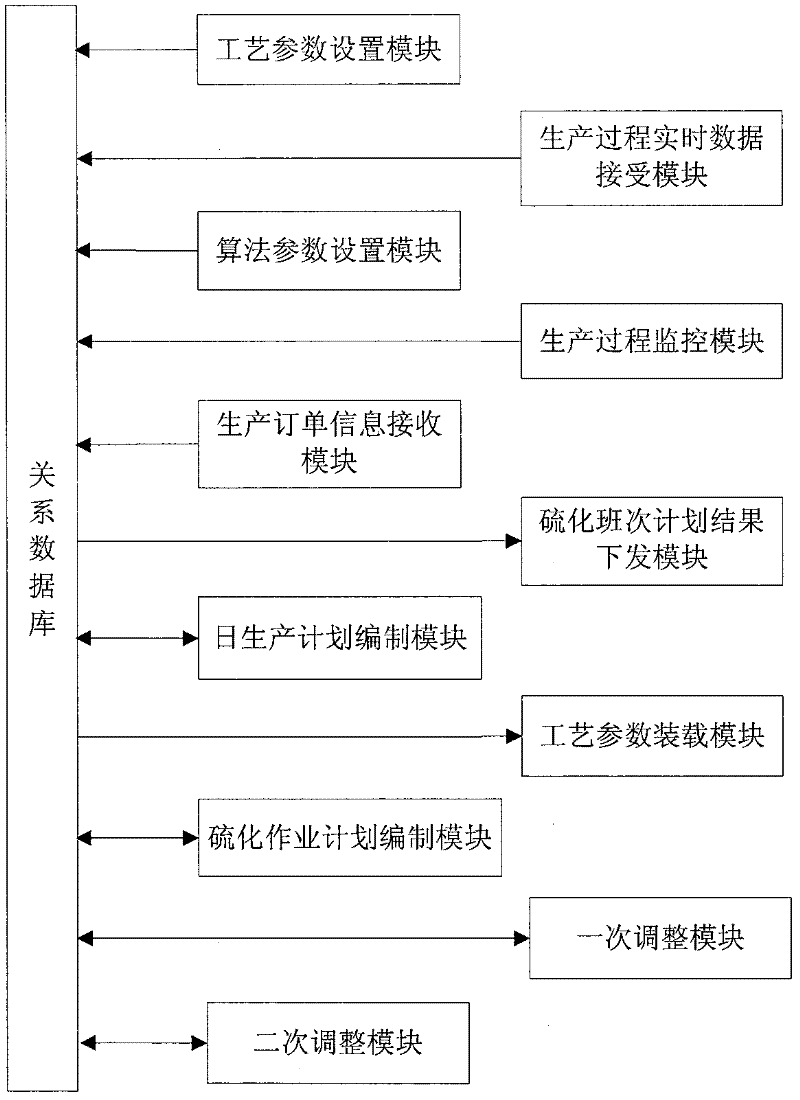

[0069] like Figure 1 to Figure 3 As shown, the vulcanization production control system applying the present invention includes as a whole, the following device layout in the multi-layer architecture that constitutes production plan preparation and implementation control:

[0070] The database server is equipped with a relational database to realize the operation of the vulcanization production management system, so as to store the production plan, real-time data and configuration data of each system in the vulcanization production process in the relational database;

[0071] The application server is used to obtain relevant parameters and process data from the relational database server to prepare the daily production plan and operation plan and store them in the relational database;

[0072] The client workstation is used to run the client system to realize data display and query, and save the data in the local computer to support the offline analysis of the data;

[0073] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com