Precision focusing mechanism taking linear motor and grating rulers as servo elements

A linear motor and servo element technology, applied in the field of precision focusing, can solve the problems of transmission backlash error, limited installation accuracy, low focusing precision, etc., to eliminate backlash error, improve focus precision, and protect the motor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0014] The invention adopts a focusing mechanism driven by a linear motor, driven by an anti-backlash nut, and the radial bearing eliminates the stress of the motor lead screw, and adopts a high-precision grating ruler as a feedback element.

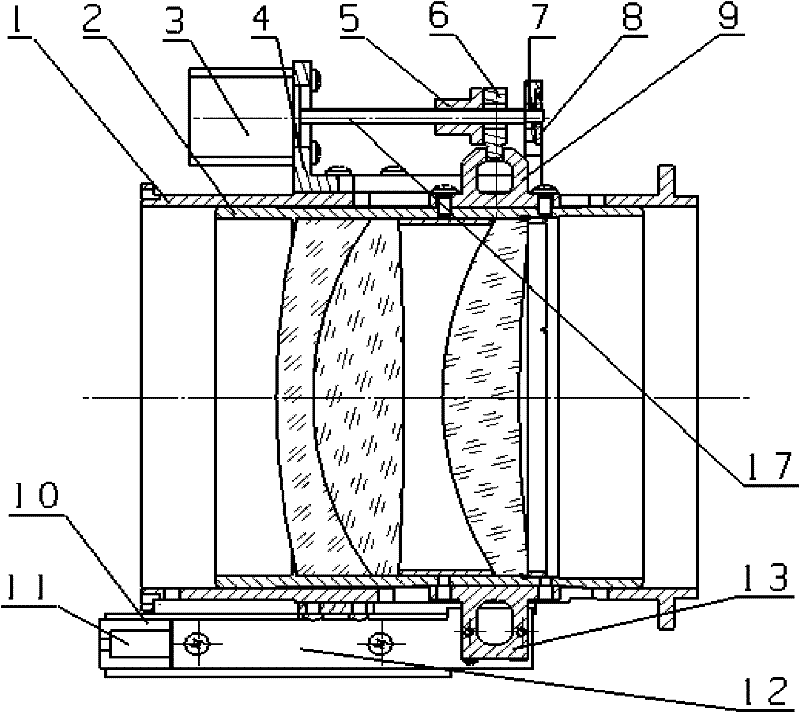

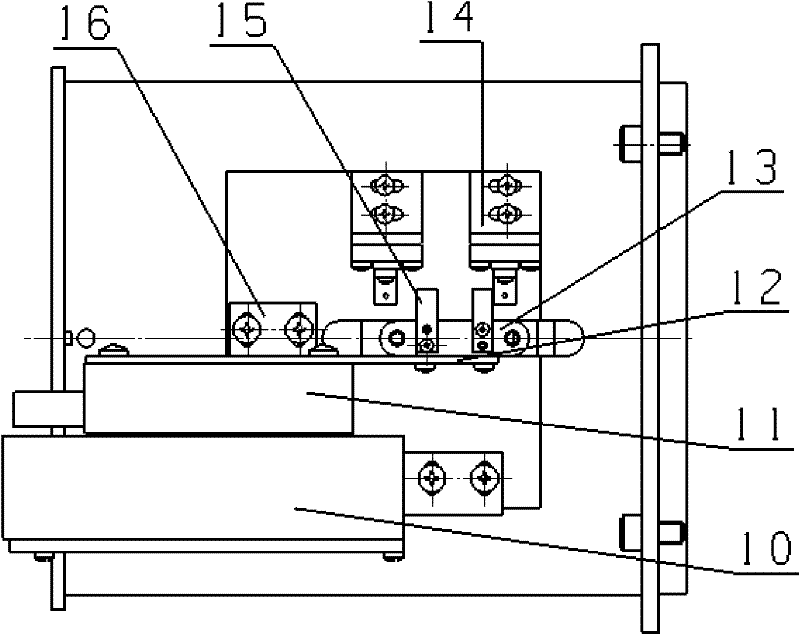

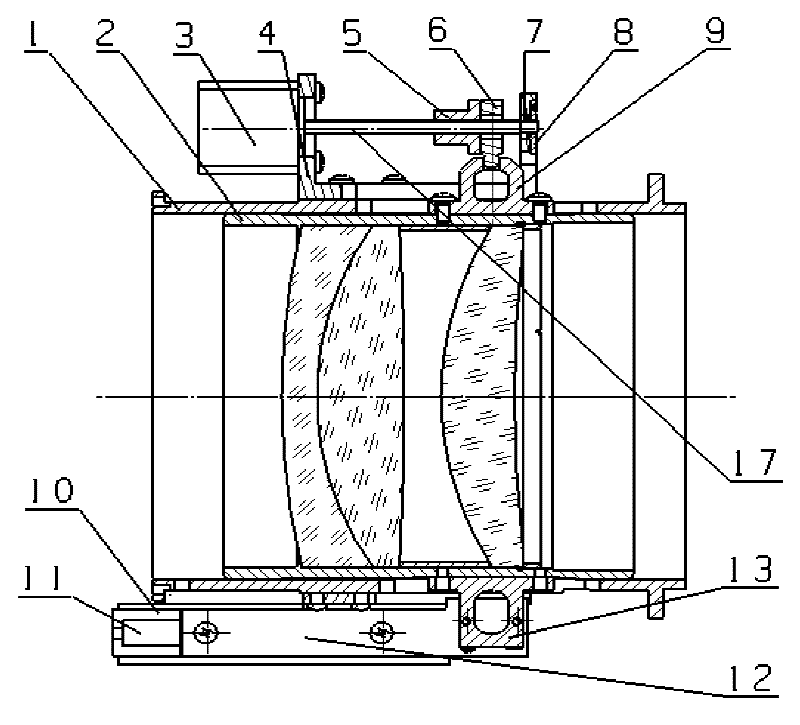

[0015] Such as figure 1 As shown, the present invention uses a linear motor and a grating ruler as the precision focusing mechanism of the servo element, including: a fixed lens barrel 1, a moving lens barrel 2, a linear motor 3, a motor fixing seat 4, an anti-backlash nut 5, a connecting ball head 6, Radial bearing 7, bearing gland 8, motor connecting block 9, grating main scale 10, grating sub scale 11, connecting piece 12, grating connecting block 13, photoelectric switch limit mechanism 14, limit plate 15 and grating seat 16; The linear motor 3 is fixed on the fixed lens barrel 1 through the motor fixing seat 4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com