Photodetection mechanics test device for simulating deep rock explosion cracking

A technology of photomechanics and experimental device, applied in soil material testing, material inspection products, etc., can solve the problem that the crack propagation law in the dynamic stress field of the explosion cannot be scientifically and comprehensively analyzed and studied, and the deep rock explosion cannot be truly reproduced. Fracture law and mechanism and other issues, to achieve the effect of easy implementation and maintenance, ensuring reliability and flexibility, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The center of the invention is: apply confining pressure to the test piece in an experimental way, simulate the ground stress in the deep rock, generate the initial static stress field in the test piece model, then pass the explosion experiment, and adopt the photomechanical method to analyze the explosion-induced stress field. Observation of the cracking process in order to study the blasting fracture phenomenon and mechanism of deep rock mass under high ground pressure, and provide scientific basis for geological excavation and blasting process.

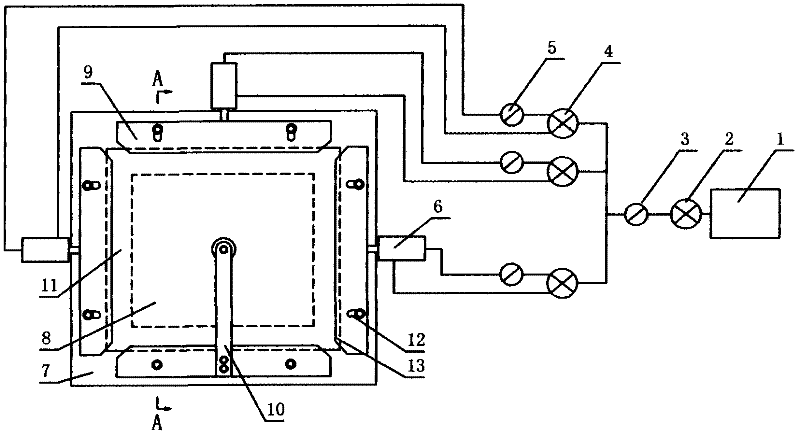

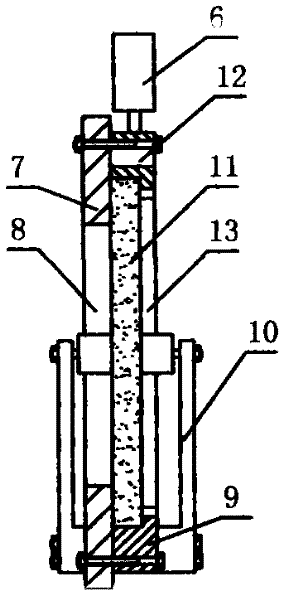

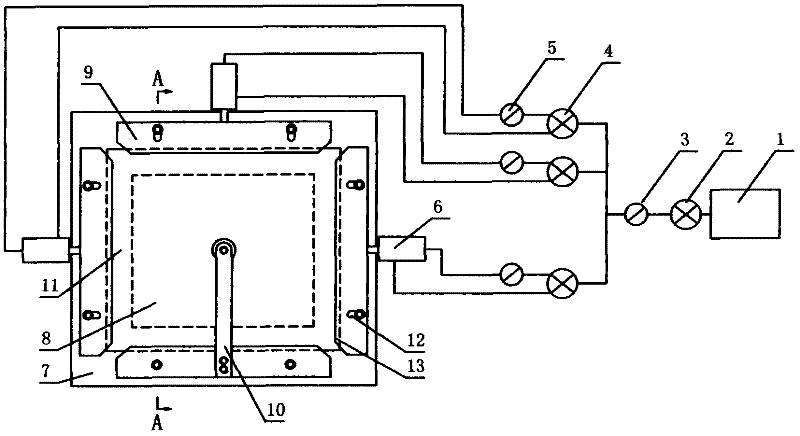

[0016] Attached below figure 1 , figure 2 The present invention is described in further detail:

[0017] An optomechanical experimental device for simulating blasting and fracturing of deep rocks. It mainly includes two parts: one part is a static loading system that can carry out stress loading on specimens along the horizontal and vertical directions; the other part is used to generate dynamic Explosive loading device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com