Portable multi-measurement-parameter low-speed impact tester

A technology for measuring parameters and low-speed impact, which is applied to measuring devices, instruments, scientific instruments, etc., and can solve the problems of large size and damage of test pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

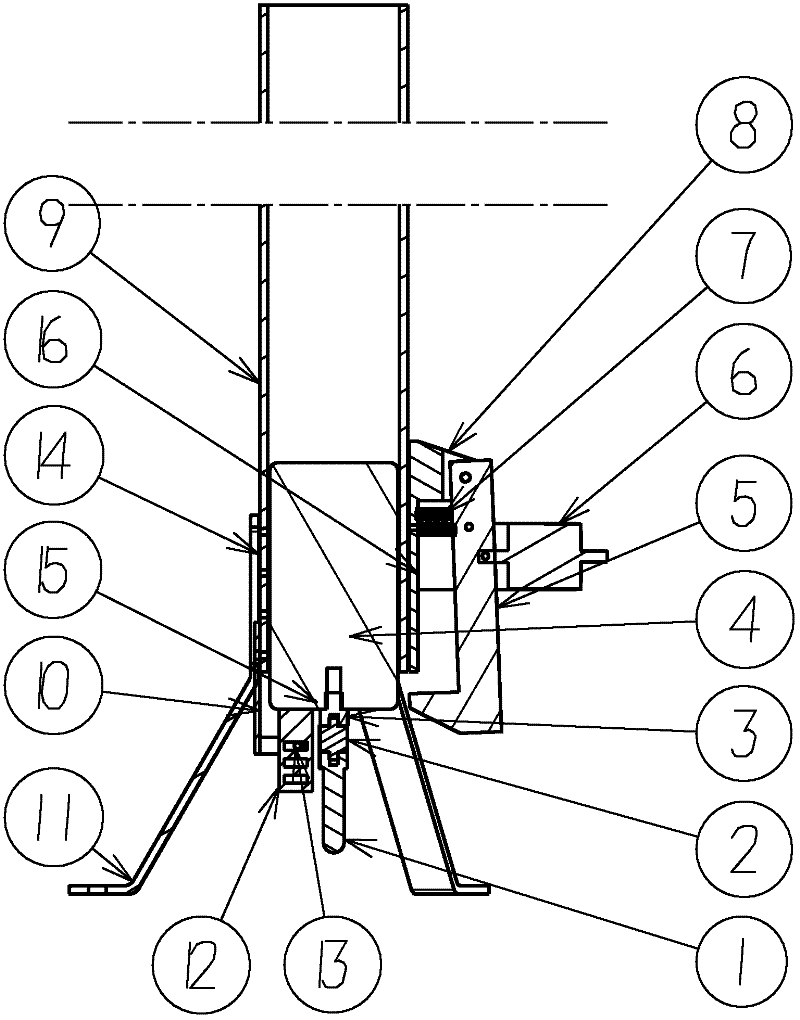

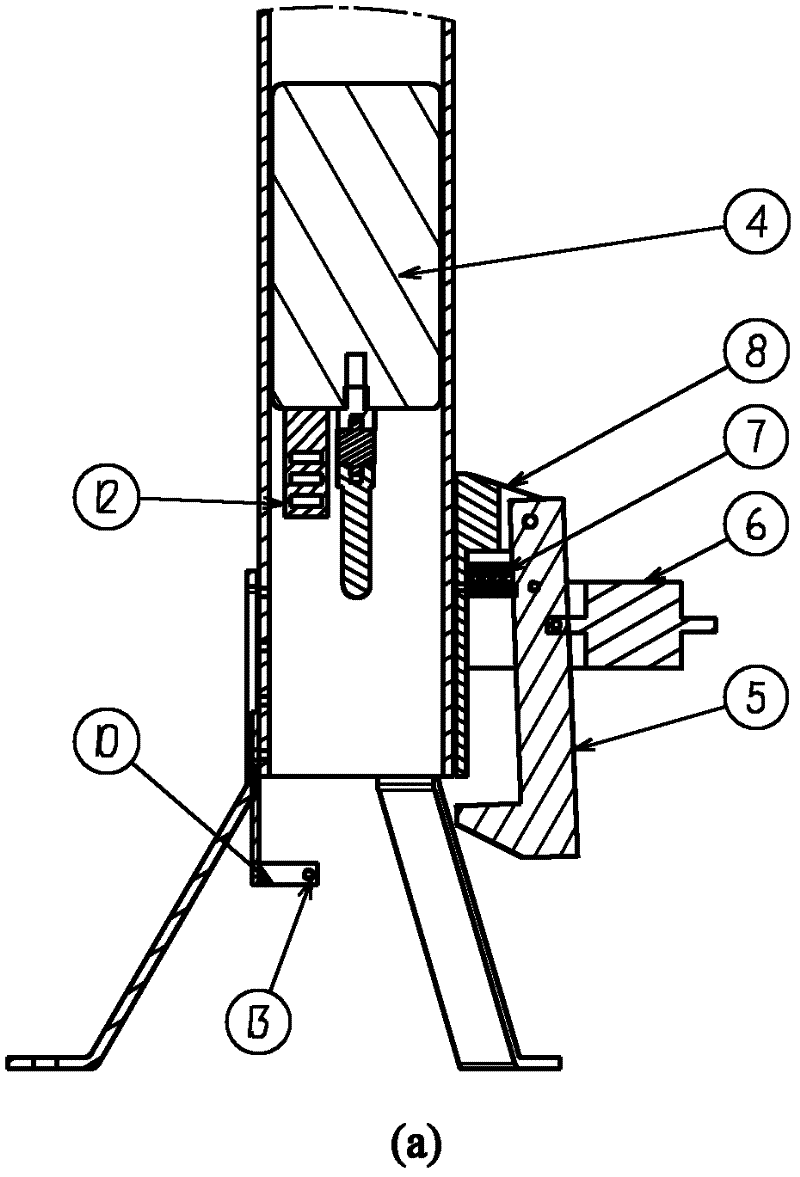

[0018] Such as figure 1 As shown, the portable low-speed impact testing machine of this embodiment includes: a support device 14, a falling weight impact measurement assembly 15 and an anti-secondary impact device 16, wherein: the falling weight impact measurement assembly 15 is arranged in the support device 14 and is connected to the support device 14 Connection, the anti-secondary impact device 16 is connected with the support device 14 .

[0019] The supporting device 14 includes: a guide cylinder 9 and a support foot 11 , wherein: the guide cylinder 9 is fixedly connected with the support foot 11 , and the bottom of the guide cylinder is connected with a secondary impact prevention device 16 .

[0020] The falling weight impact measurement assembly 15 includes: an impact head 1, a force sensor 2, a force sensor joint 3, a drop weight 4, a grid plate 12, an optical fiber sensor 13 and an optical fiber sensor bracket 10; wherein: the impact head 1, the force sensor 2. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com