Pot-type calcining furnace

A tank-type calciner and calciner technology, which is applied in the field of calciner, can solve the problems of high cost, low heat energy utilization rate, and complex structure, and achieve the effects of high production efficiency, high heat energy utilization rate, and unique structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

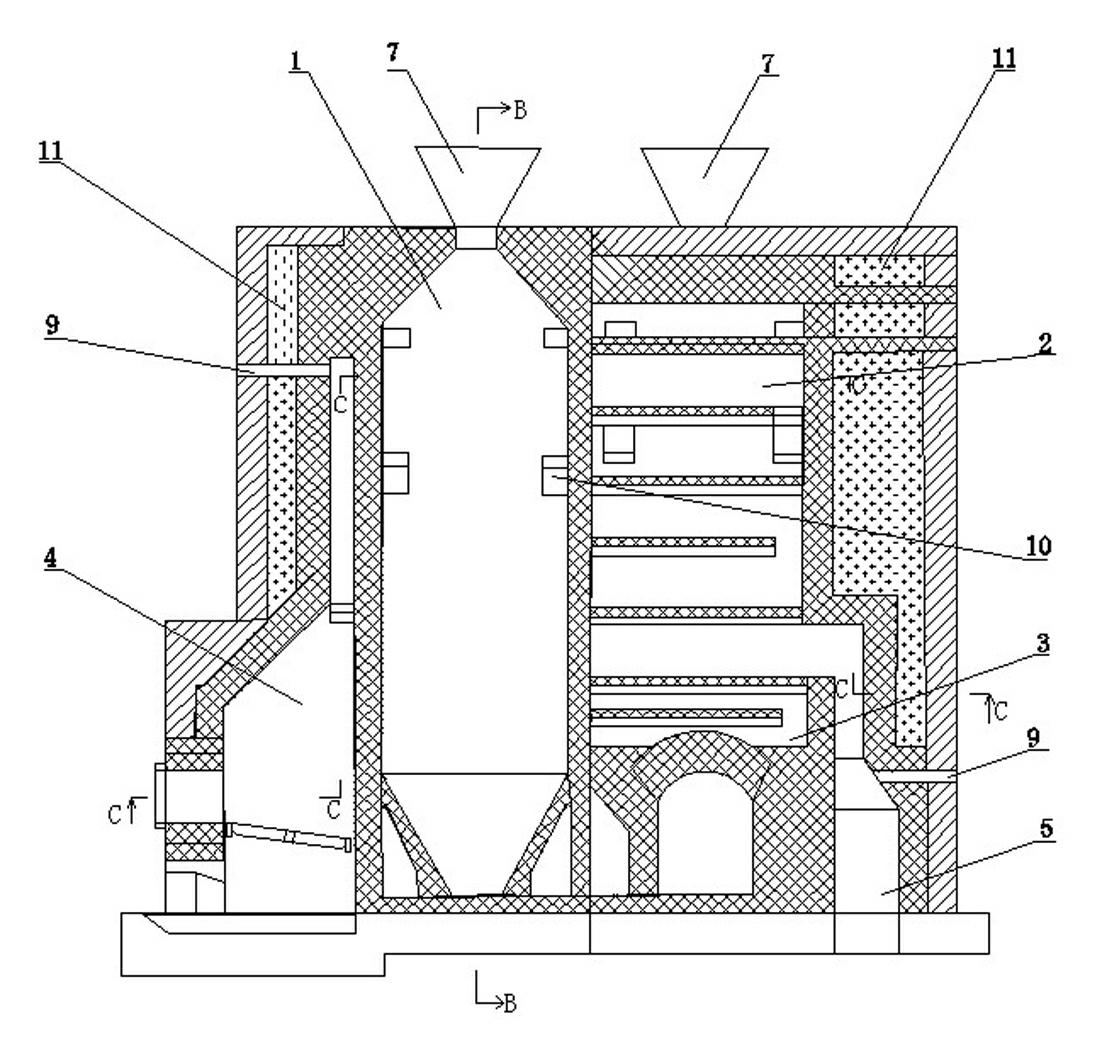

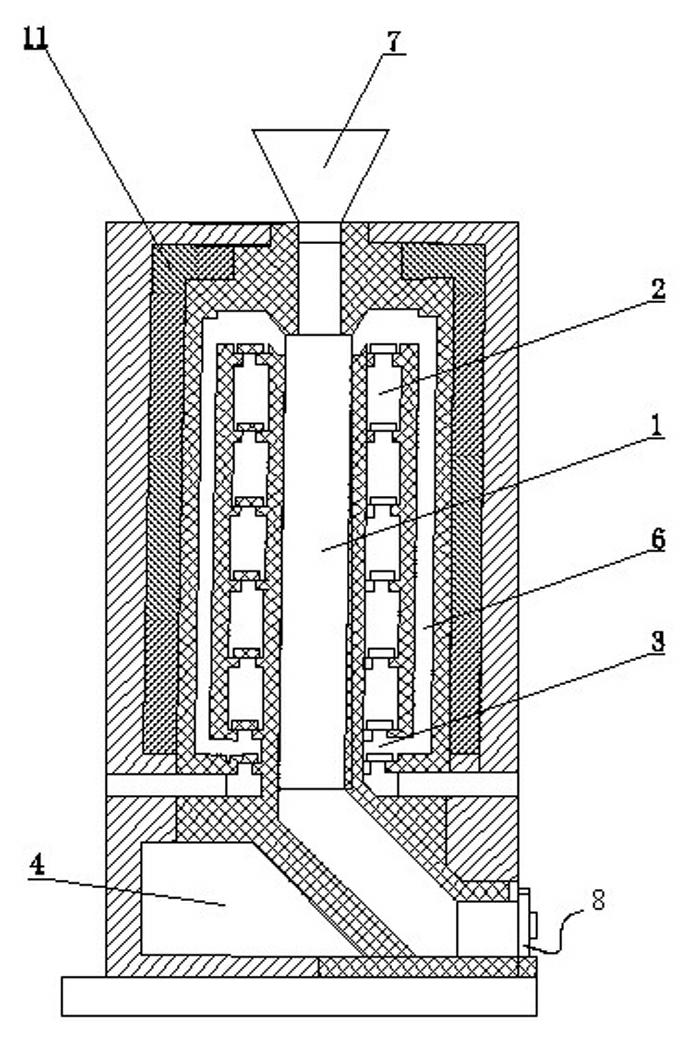

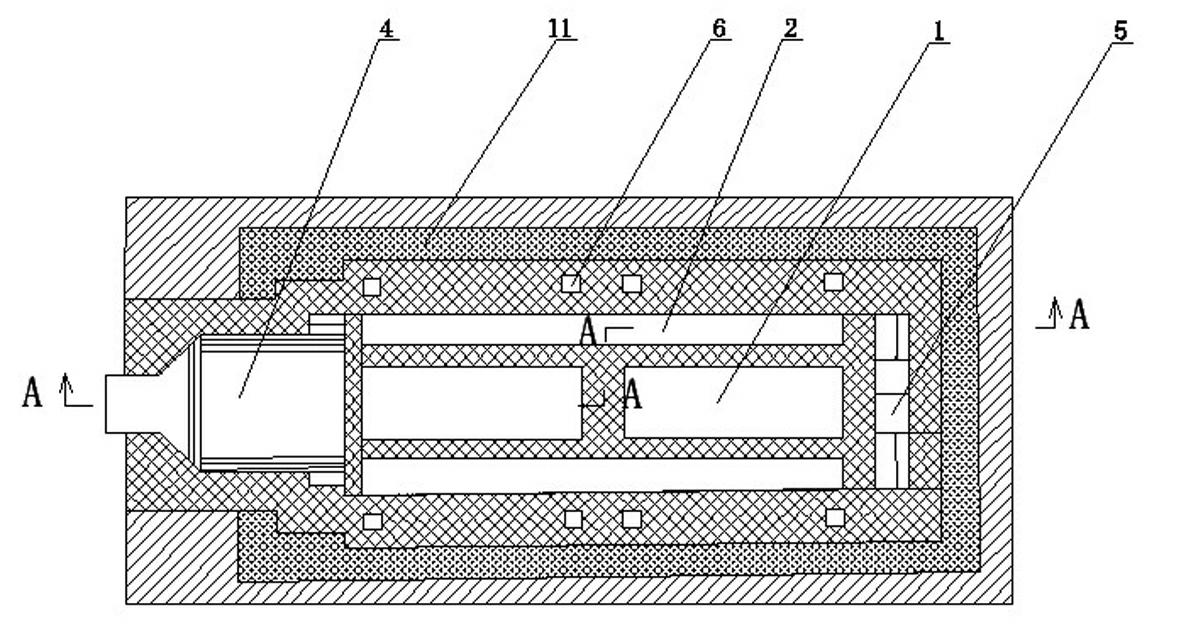

[0019] The structure of the pot calciner is as follows: figure 1 , figure 2 , image 3 shown, of which figure 1 is along image 3 The sectional view of A-A in the middle.

[0020] The pot calciner consists of a calciner 1, a combustion chamber 4, a heating channel 2, an air channel 3, a volatilization channel 6, a flue 5, a feeding system 7 and a discharge system 8. The main structure of the tank type calciner is two vertically arranged calciner tanks 1 arranged left and right, and the specification of each calciner tank is 1520 mm in length x 470 mm in width x 3500 mm in height. There are five layers arranged up and down on the front and rear sides of the calciner 1, and the specifications are 3270 mm long × 240 mm wide × 411 mm high. The heating channel 2 is connected to the combustion chamber 4 at the entrance of the heating channel 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com