Double-seal valve seat

A double sealing and valve seat technology, applied in the direction of valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of poor sealing effect and large torque, so as to increase the service life, reduce the opening torque and ensure the sealing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

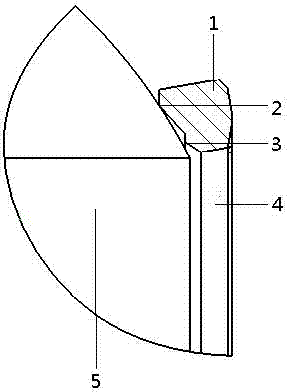

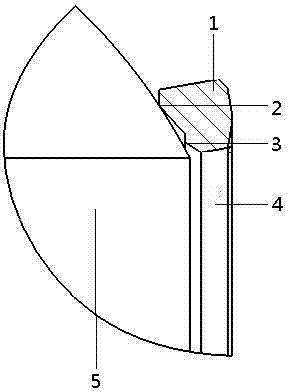

[0013] As shown in the figure, two sealing rings are arranged on the valve seat sealing body 1 on the valve seat 4, the lower sealing ring 3 forms an included angle of 5°-10° with the vertical direction of the valve seat 4, and the upper sealing ring 2 and the valve seat 4 The vertical direction forms an included angle of 15°-25°, and the traditional single-line seal is changed to a double seal while making full use of the elastic deformation characteristics of the material PTFE to achieve a good sealing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com