Hydraulic torque converter for fork truck

A technology for torque converters and forklift trucks is applied in the field of hydraulic torque converters for forklift trucks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

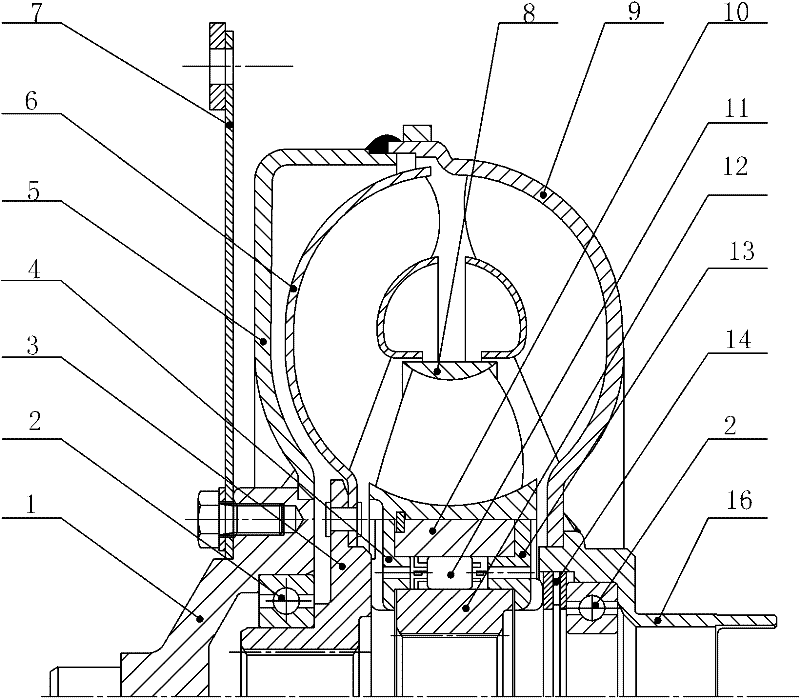

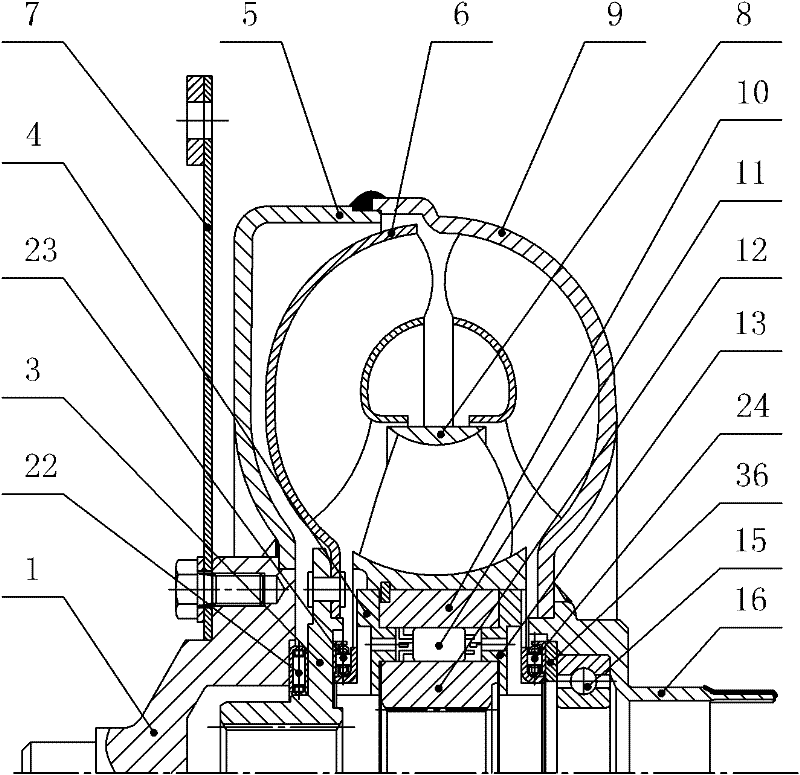

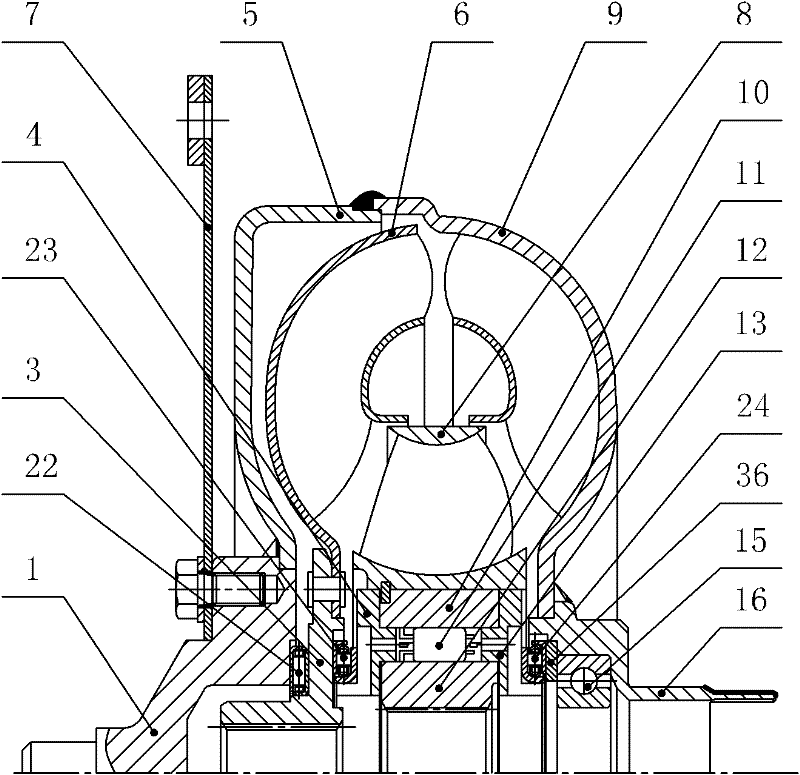

[0019] like figure 2 Shown is a schematic structural view of the hydraulic torque converter of the present invention, a hydraulic torque converter for forklifts, including a cover wheel assembly, a turbine assembly, a pump wheel assembly and a guide wheel assembly; the cover wheel assembly includes a cover hub 1, a cover Wheel housing 5; turbine assembly includes turbine hub 3, turbine body 6; pump wheel assembly includes pump hub 16, pump wheel body 9; guide wheel assembly includes front retainer 4, rear retainer 13, inner race 12, one-way clutch 11. Outer race 10, guide wheel body 8; a three-pack bearing is arranged between the cover wheel hub 1 and the turbine hub 3, a three-pack bearing 23 is arranged between the turbine hub 3 and the front retainer 4, and the rear retainer 13 and the pump There are three-pack bearings 24, thrust plates 36 and ball bearings 15 between the hubs 16; A three-pack bearing 23 is arranged between the rear retainer 13 and the pump hub 16 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com