Vertically and horizontally combined gas pressure spring

A gas spring, combined technology, applied in the field of spring manufacturing, can solve the problems of insufficient deformation stroke of gas spring, small adjustment range of softness and hardness, and high requirements for parts matching, and achieves saving transportation cost, good ventilation, and large deformation stroke. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

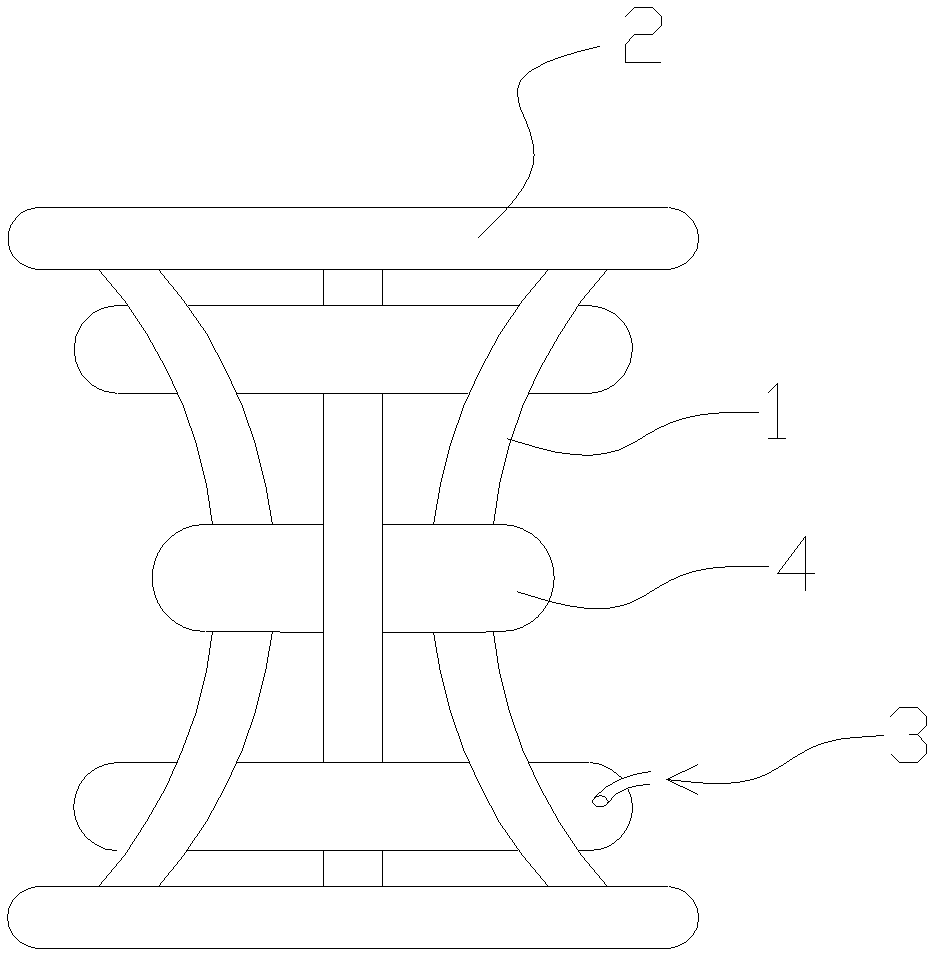

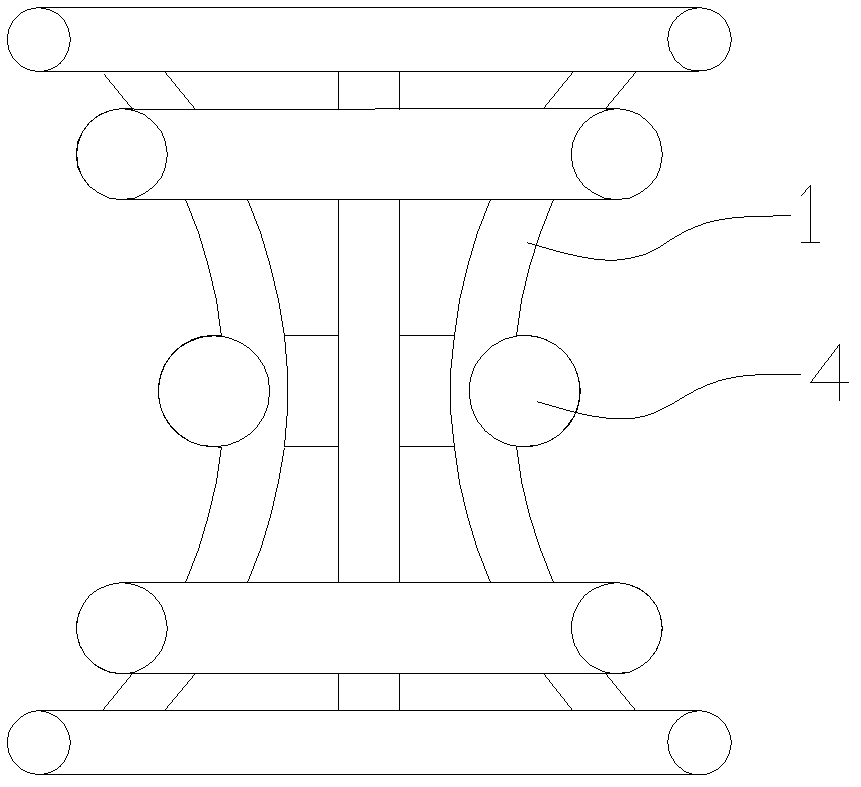

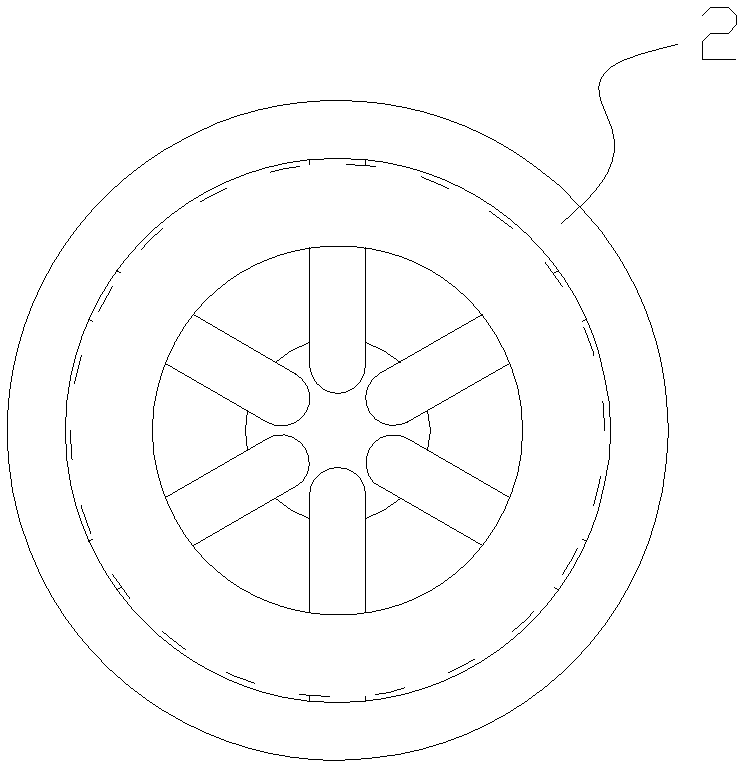

[0022] Such as Figure 1-Figure 3 As shown, a vertically and horizontally combined gas spring described in the present invention includes a spring body, and the spring body is composed of a plurality of gas column bands 1 with pressure gas accommodation chambers, and the plurality of gas column bands 1 are vertically arranged And it is covered with a transverse hollow annular airbag 4, the upper and lower ends of the air column belt 1 are respectively positioned and connected, and the gas pressure in the accommodating chamber is adjustable. The upper and lower ends of the plurality of air column strips 1 are respectively connected to a positioning member 2 and there are horizontal and vertical ventilating passages between them. The air column strips 1 communicate with each other and are provided with at least one vent hole 3 communicating with the accommodating cavity. There may also be two vent holes 3, one for inflation and one for exhaust. The air column belt 1 is lined wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com