Application method of detachable carrying device

An application method and a technology of a bearing device, applied in the processing of building materials, preparation of building components on site, pillars, etc., can solve problems such as inability to ensure safe long-term use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

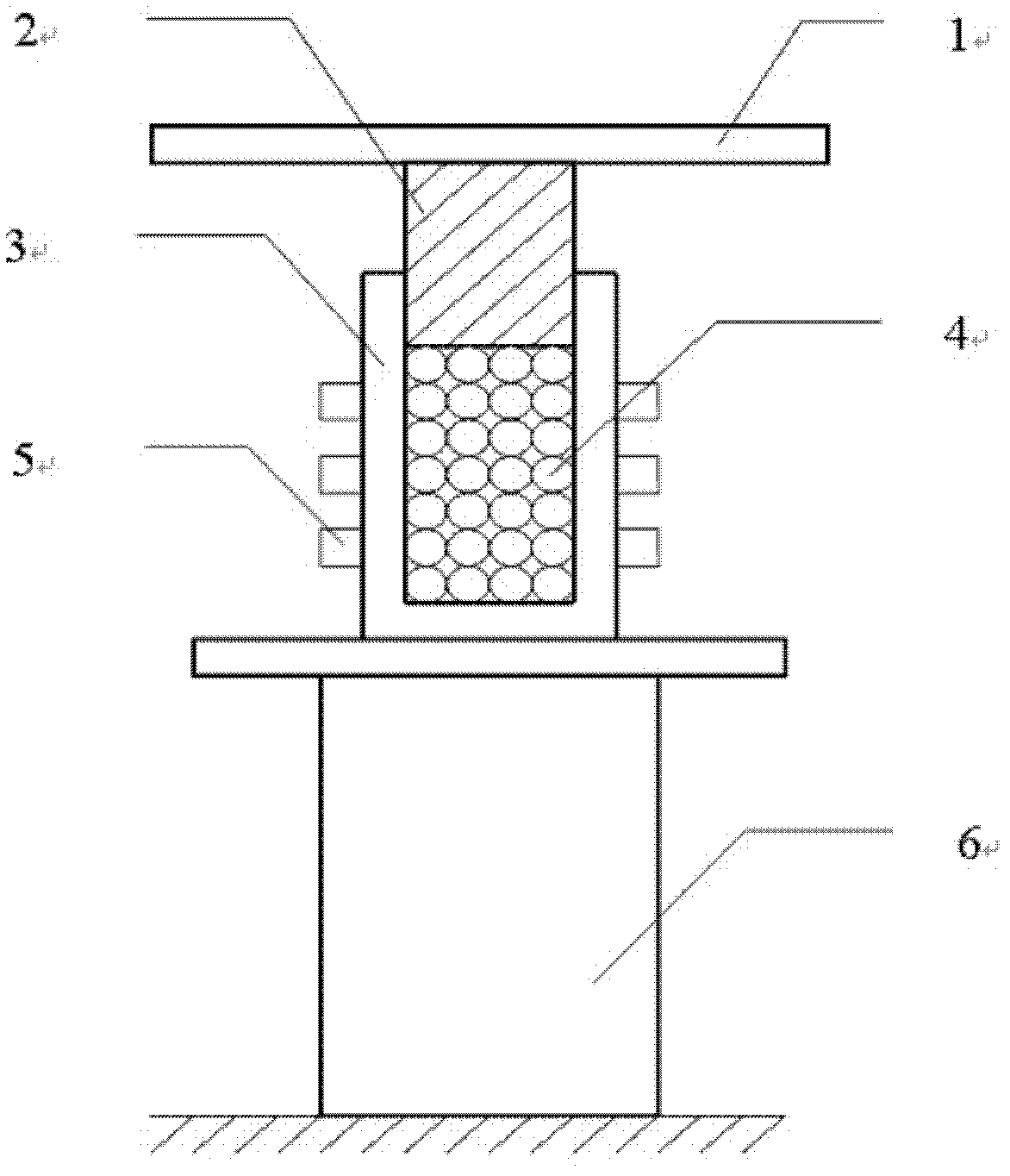

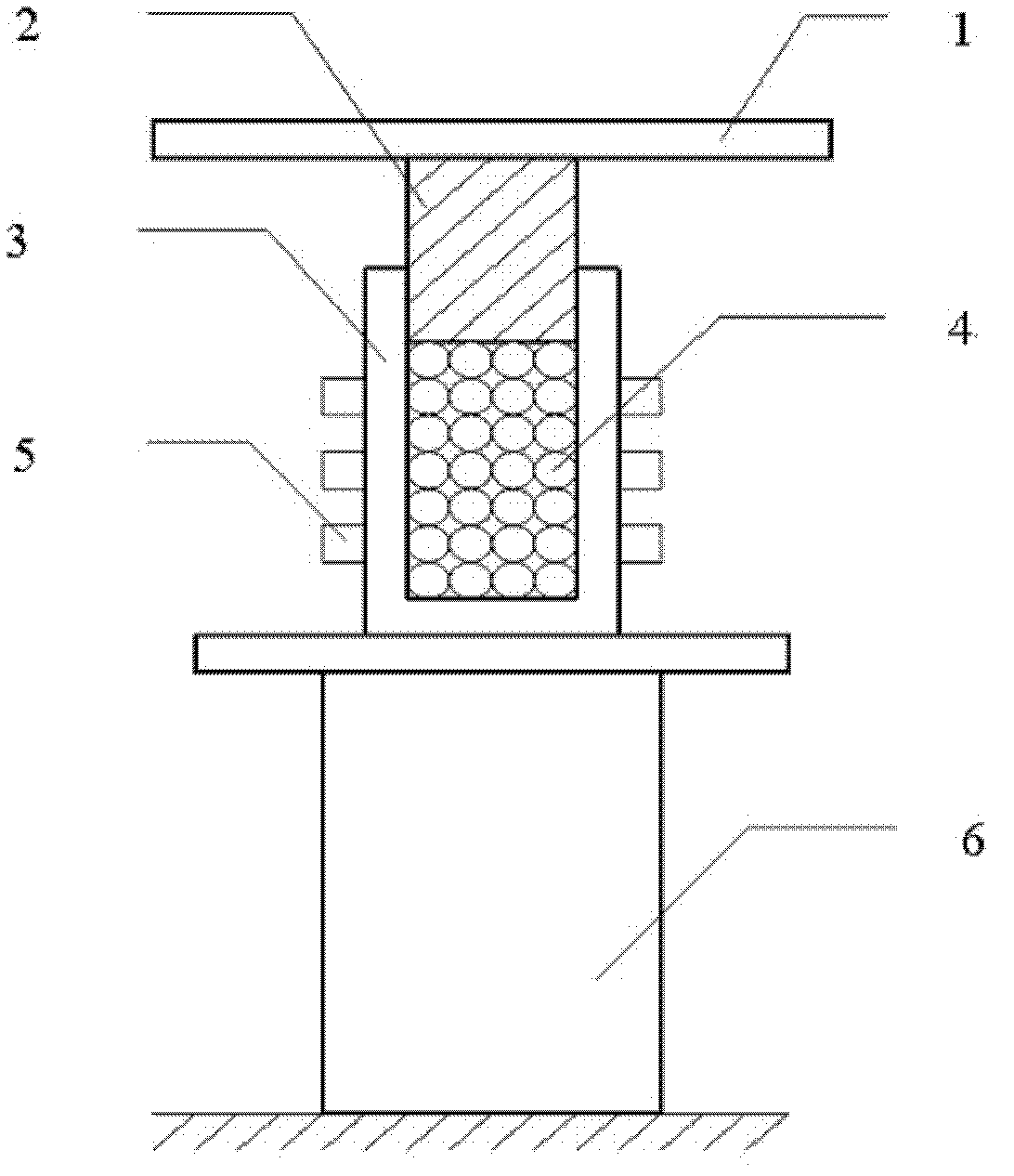

[0028] When the building construction site needs to bear the force-bearing components, implement the application method of a detachable load-bearing device of the present invention, including the force-bearing components [1], the outer cylinder [2], the inner column [3], the steel ball [4] , bolts [5], supporting members [6].

[0029] The steps to apply the method are as follows:

[0030] (1) Before the stressed member [1] is loaded with force, install a supporting member [6] with a suitable height under the point where the stressed member [1] needs to be supported. The bottom of the supporting member [6] and the ground can be Fixed connection with a firm base that bears the load;

[0031] (2) Weld and fix the steel plate on the top of the support member [6];

[0032] (3) Install the outer cylinder [2] on the steel plate fixedly installed on the top of the supporting member [6], the bottom of the outer cylinder [2] is in contact with the upper surface of the steel plate, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com