Reusable concrete floor steel bar pre-supporting device

A pre-support and concrete technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of open welding of steel bar stools, large processing deviations, and increased construction costs, so as to achieve convenient installation and disassembly and ensure processing accuracy , The effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

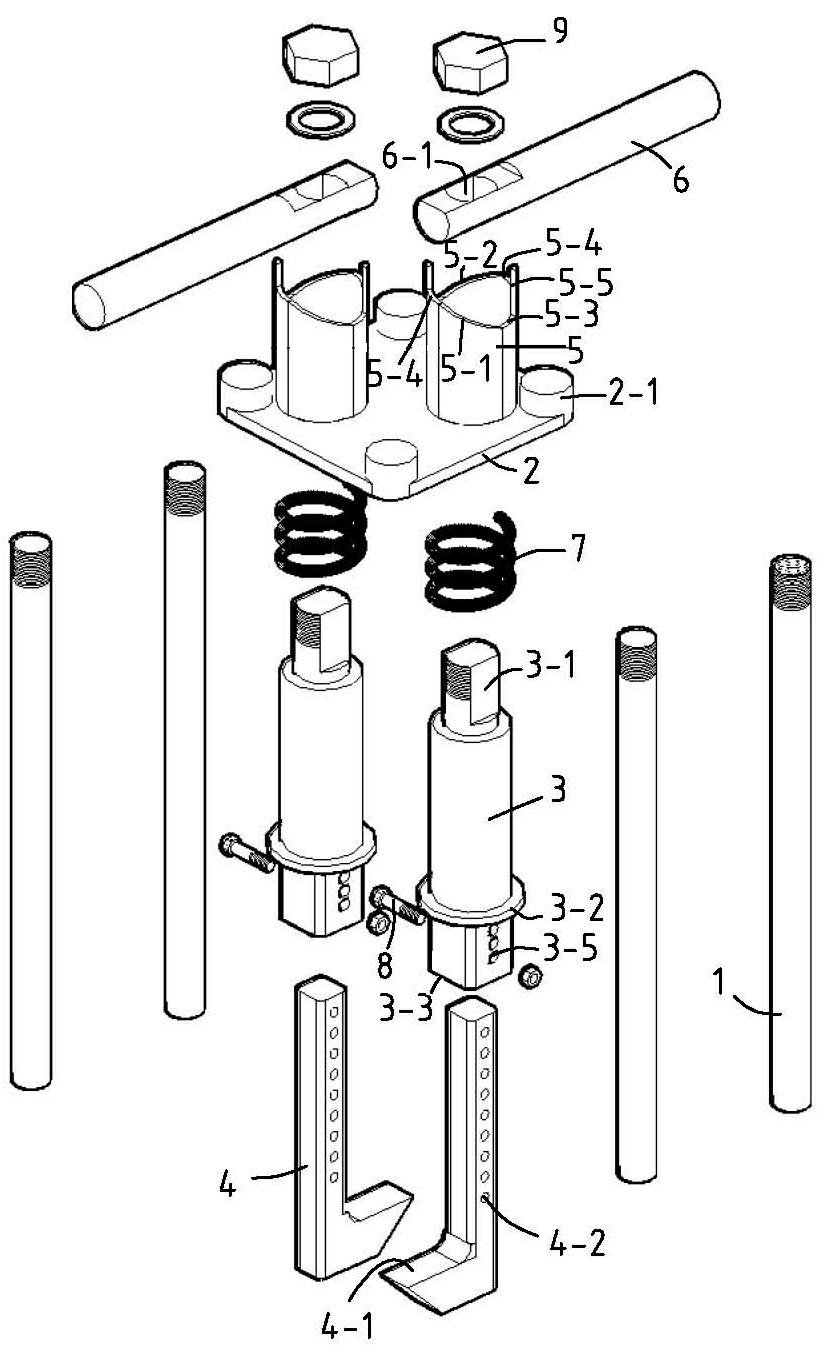

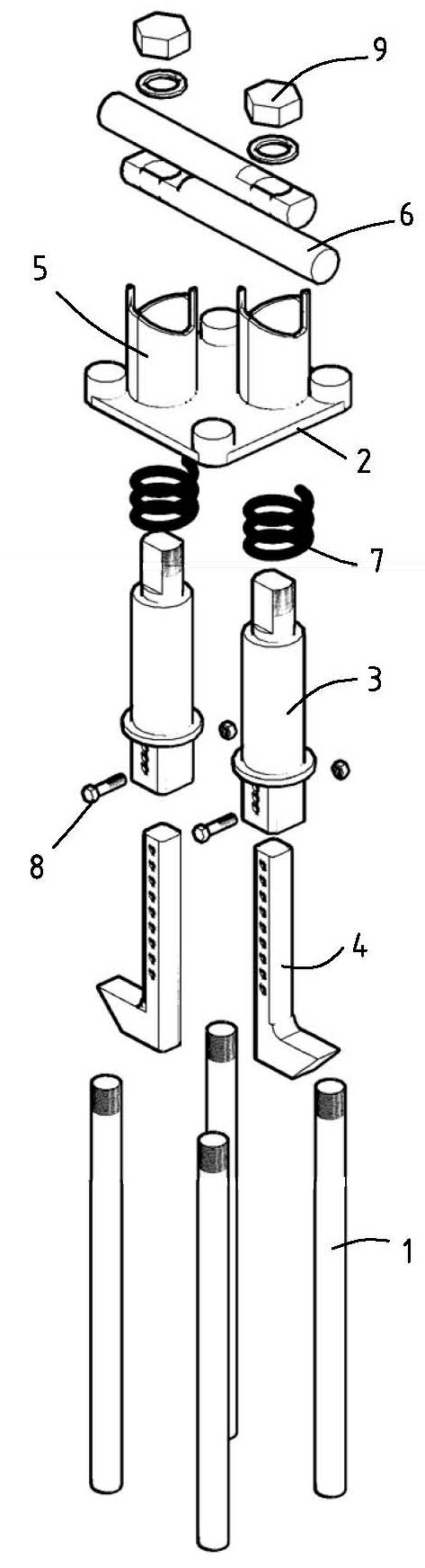

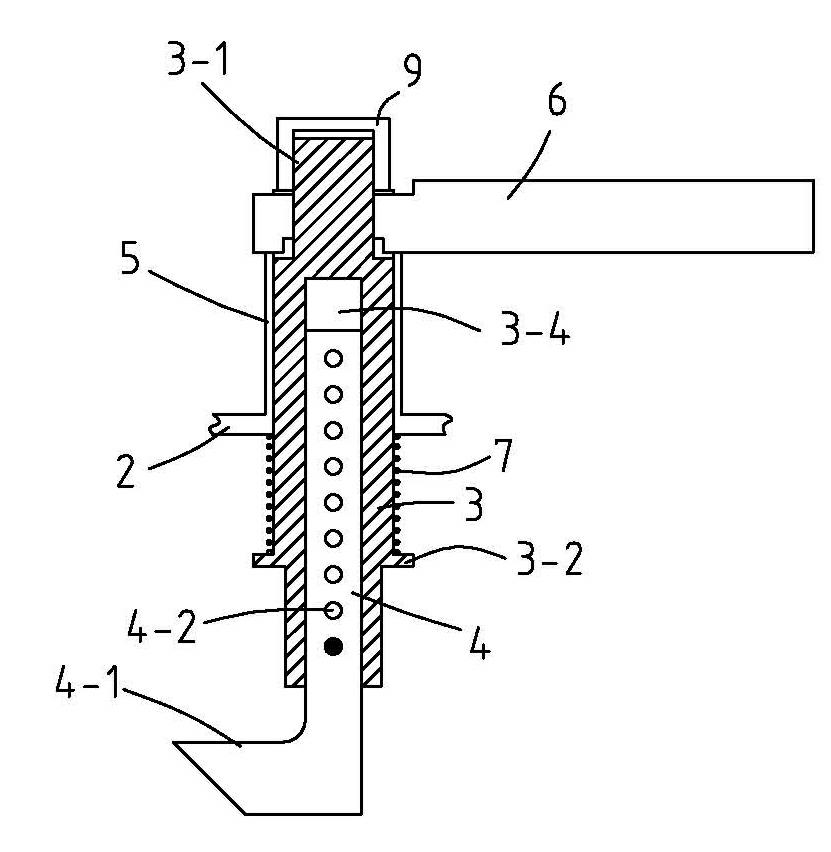

[0015] A kind of embodiment of reusable concrete floor reinforcement pre-support device, see figure 1 , figure 2 and image 3 , the steel bar pre-supporting device includes four cylindrical columns 1, square (square or rectangular) positioning steel plate 2, hanging arm support arm 3 and steel bar hanging arm 4; four corners of the steel plate are provided with threaded hole columns 2- 1. As a support, the four columns are vertically fixed on the four corners of one side of the square positioning steel plate by screwing into the hole column (the other side of the steel plate can also be locked with nuts), on the diagonal of the surface of the square positioning steel plate Two holes are arranged symmetrically to the center of the square positioning steel plate. Sleeves 5 are arranged respectively along the walls of the two holes above the other side of the square positioning steel plate. Two symmetrical holes are arranged on the top wall of the sleeve. The first spiral risi...

Embodiment 2

[0018] Referring to Embodiment 1, the content disclosed in Embodiment 1 should also be used as the content of this embodiment. In this embodiment, in order to rotate and pull the wrench arm, the slope of the spiral rising slope described in the embodiment should not be too large, so this embodiment The spiral rising slope is a spiral rising slope with an initial angle of 30 degrees.

Embodiment 3

[0020] Referring to Embodiment 1, the content disclosed in Embodiment 1 should also be used as the content of this embodiment. In Embodiment 1, in order to stabilize the arm on the slope, a platform is set at the end of the slope. This embodiment In the example, in order not to slide over the positioning platform due to excessive force after the wrench arm is pulled to the positioning platform, between the positioning platform at the low end of the first spiral rising slope and the high terminal positioning platform of the second spiral rising slope, Limiting posts 5-5 are respectively arranged between the positioning platform at the high end of the first spiral rising slope and the positioning platform at the low end of the second spiral rising slope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com