Building block compositely filled with phase change material and thermal insulation material

A technology of thermal insulation materials and phase change materials, applied in building materials, building components, walls, etc., can solve problems such as fire safety hazards, easy cracking and falling off, complex construction procedures, etc., to achieve good thermal insulation performance, reduce thermal bridges, and thermal insulation performance and good fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

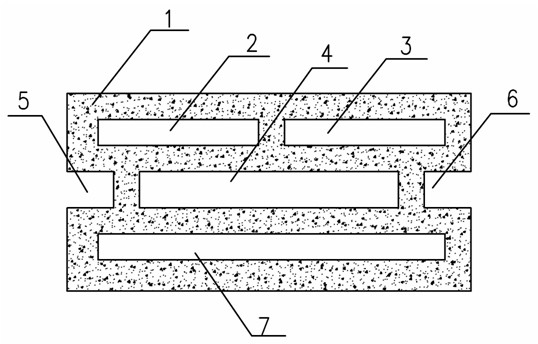

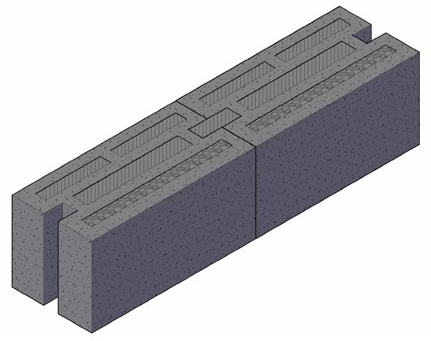

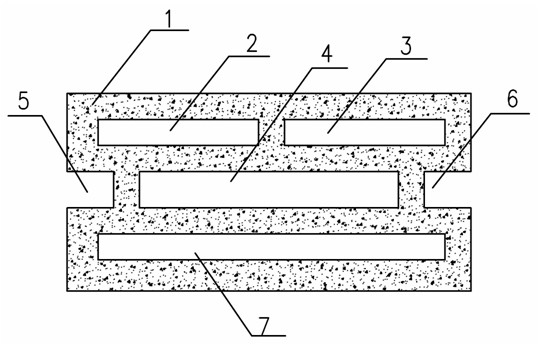

[0015] like figure 1 As shown, it is a block filled with phase change materials and thermal insulation materials, including a block body 1 made of concrete, with a size of 390mm*190mm*190mm, which meets the standard of ordinary small concrete blocks, and is located in the middle of both sides of the block Two grooves 5 and 6 of the same size are set, and the size is 45mm*35mm*190mm. Four rectangular through-holes 2, 3, 4, 7 are arranged inside the body, and the four through-holes are arranged in three rows of upper, middle and lower and are arranged staggered from each other. Two through holes 2 and 3 of the same size are arranged in the first row above, and the size is 155mm*25mm*190mm. A through hole 4 is set in the second row in the middle, with a size of 250mm*35mm*190mm, which is set in the same row as the grooves 5 and 6, and a longer through hole 7 is set in the third row below, with a size of 335mm*25mm*190mm . For blocks of this size, the volume capacity of through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com