Direct-driving oscillating gate passage

A swing type, channel technology, applied in the field of gate channels, can solve the problems of the complexity of the installation of the safety channel, inconvenient disassembly of the rotating shaft, increased maintenance difficulty, etc. The effect of reducing installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

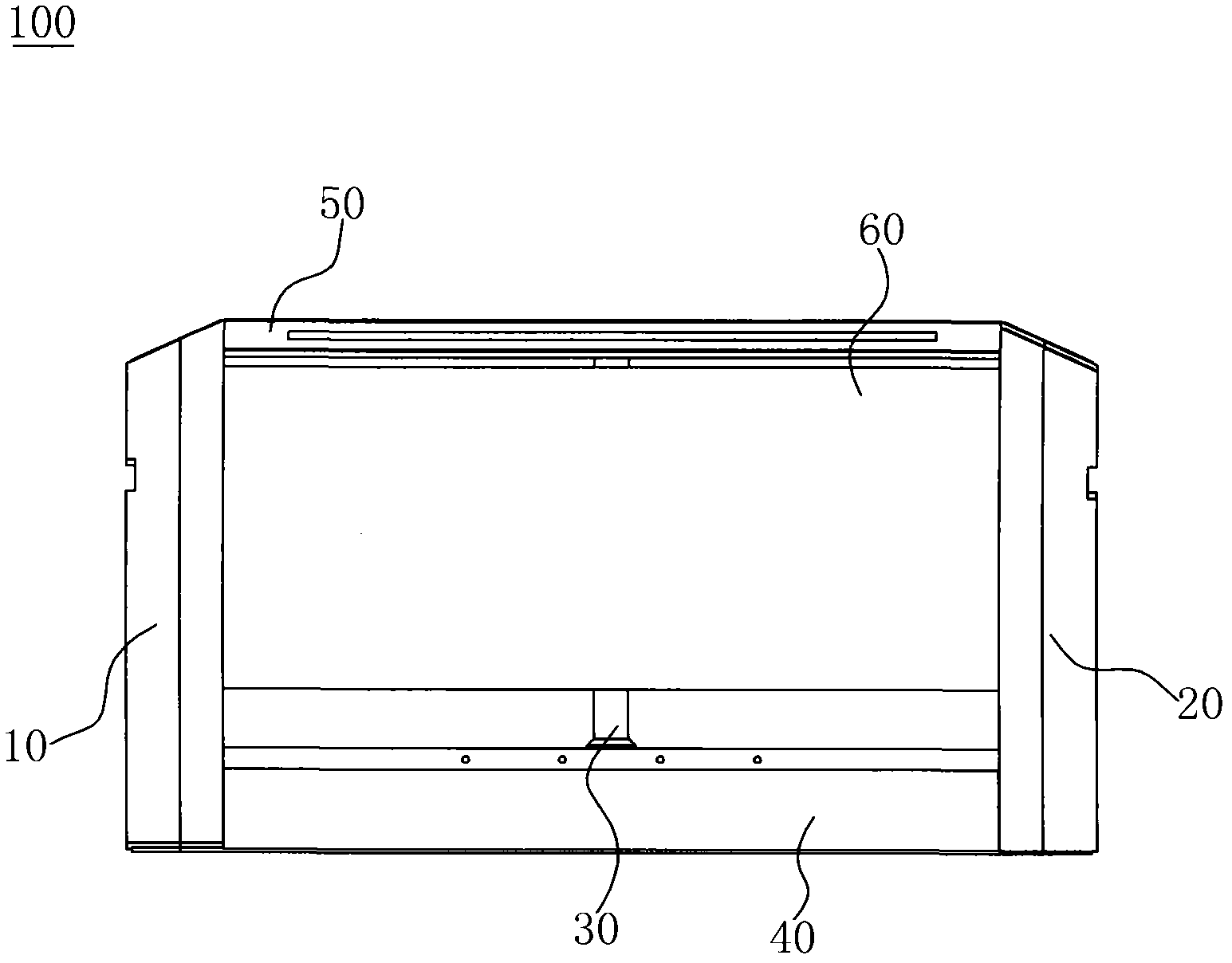

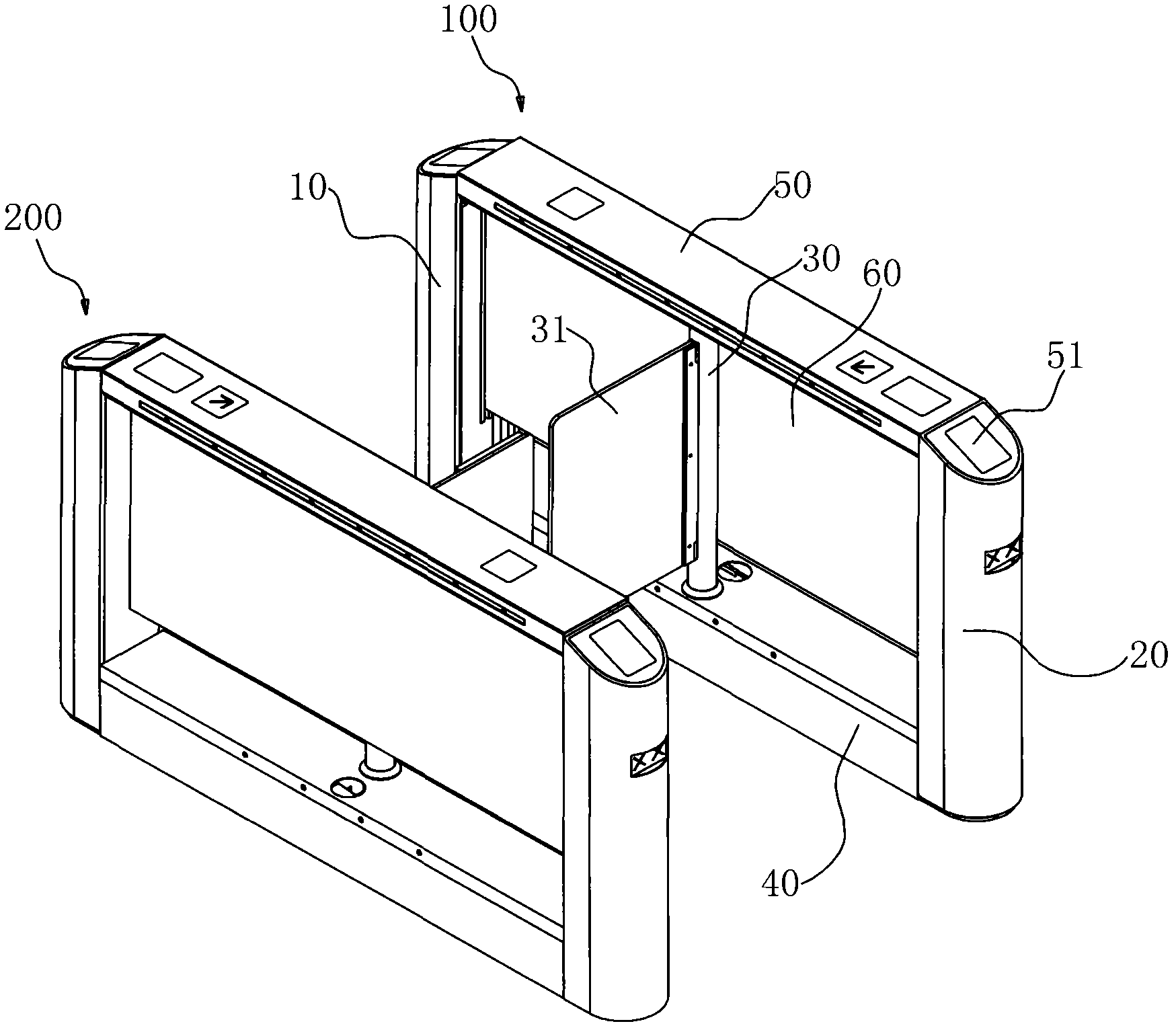

[0017] like figure 1 and figure 2 As shown, the direct-drive swing gate channel is composed of two sets of channel bases 100 and 200. The two sets of channel bases are arranged side by side and facing each other on both sides of the channel. The two channel bases are structurally symmetrical bases. The channel base 100 has a support frame body, which includes front and rear columns 10 and 20, and a control installation box 40 at the bottom of the support frame body, and the control installation box 40 is located between the front and rear columns. The control installation box is a cuboid structure arranged horizontally, in which communication and control components are arranged, and a baffle 60 is assembled in the support frame, and the two ends of the baffle 60 are fixedly arranged on the front and rear columns. The upper end surface of the control installation box is provided with a driving column 30 of the access door, and the driving column 30 is located on one side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com