Fiber fabric with open pore structure and manufacturing method for fiber composite material part with open pore structure

A fiber composite material and open-pore structure technology, applied in non-woven fabrics, textiles and papermaking, can solve the problems of stress concentration and reduce the strength of fiber composite material parts, reduce stress concentration, facilitate mass production, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

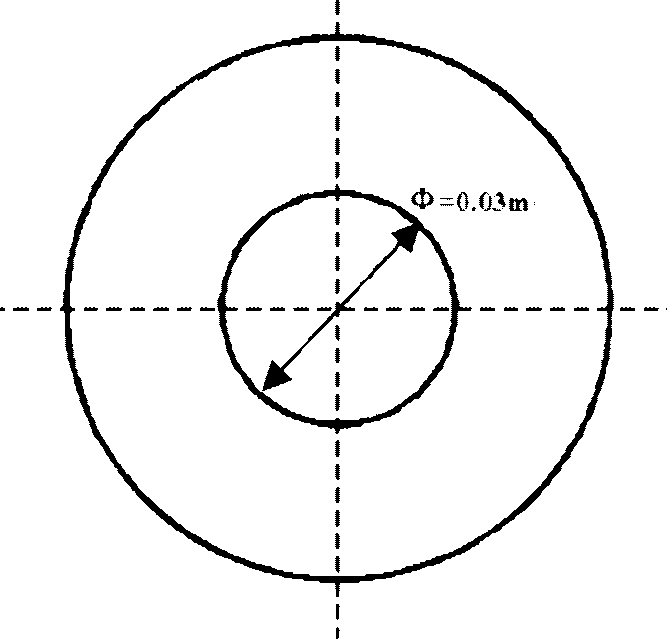

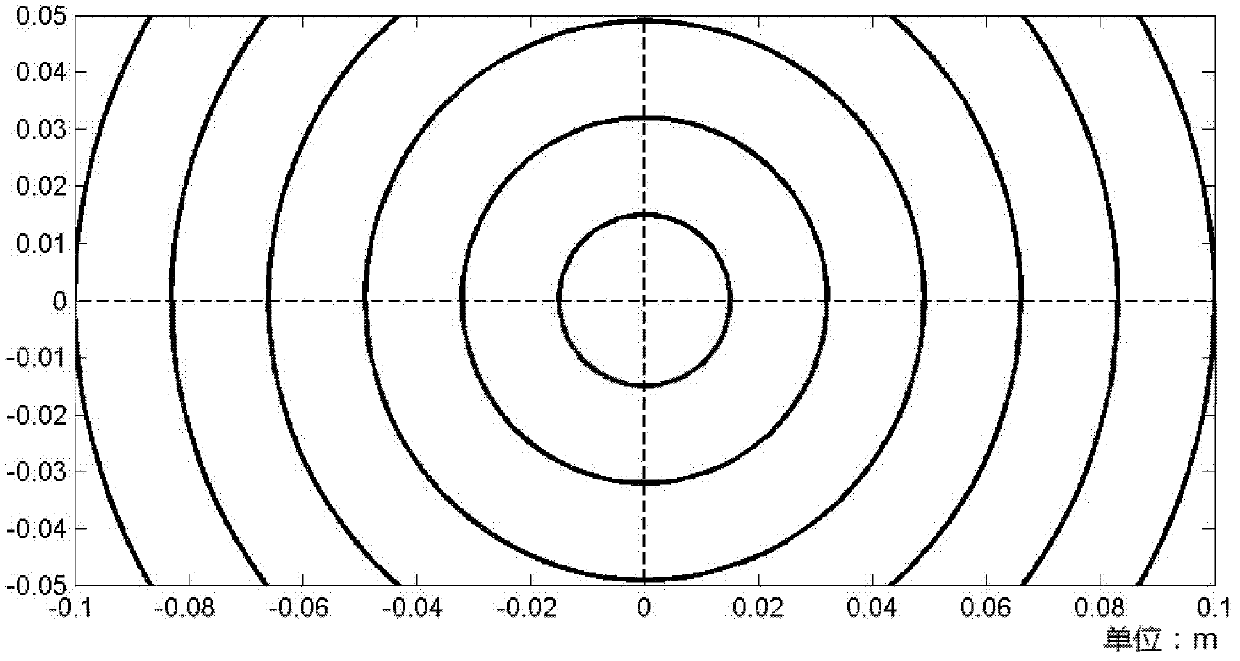

[0071] In this implementation, the raw materials and the hole structure of the carbon fiber / epoxy resin composite laminate with the open structure are exactly the same as those of Comparative Example 1. The difference is that in the carbon fiber / epoxy resin composite laminate with an open structure, the carbon fiber fabric with an open structure formed by the carbon fiber prepreg tape under the action of the adhesive has a certain shape of fiber tracks. The trajectory is represented by the following elliptic curve family equation (1):

[0072] x 2 ( r + vt ) 2 + y 2 ( r + t ) 2 = 1 ...

Embodiment 2

[0084] In this implementation, the raw materials and the hole structure of the carbon fiber / epoxy resin composite laminate with the open structure are exactly the same as those of Comparative Example 1. The difference is that in the carbon fiber / epoxy resin composite laminate with an open structure, the carbon fiber fabric with an open structure formed by fixing the dry carbon fiber with a suture has a fiber track of a certain shape, which is composed of the following The elliptic curve family equation (3) expresses:

[0085] x 2 ( r + vt ) 2 + y 2 ( r + t ) 2 = 1 - ...

Embodiment 3

[0096] In this implementation, the raw material and opening structure of the carbon fiber / unsaturated polyester resin composite laminate with an open structure are exactly the same as those in Comparative Example 2. The difference is that in the carbon fiber / unsaturated polyester resin composite laminate with an open structure, the carbon fiber fabric with an open structure formed by fixing the dry carbon fiber with a suture has a fiber track of a certain shape. The elliptic curve after the overall rotation of 15° by the above elliptic curve family equation (4).

[0097] Figure 5 It is a schematic diagram of laying the elliptical curve family fiber track of the carbon fiber fabric. The dotted lines in the figure are the major axis and the minor axis of the ellipse trajectory, respectively, and the solid lines are some fiber trajectories in the carbon fiber fabric.

[0098] The preparation method of the above-mentioned open-pore structure carbon fiber / unsaturated polyester r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com