Application of Lactobacillus casei LC2W in preparation of Alpha-glycosidase inhibitor

A glycosidase inhibitor, the technology of Lactobacillus casei, is applied in the field of preparation of Alpha-glucosidase inhibitor by Lactobacillus casei LC2W to achieve the effect of inhibiting the activity of alpha-glucosidase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

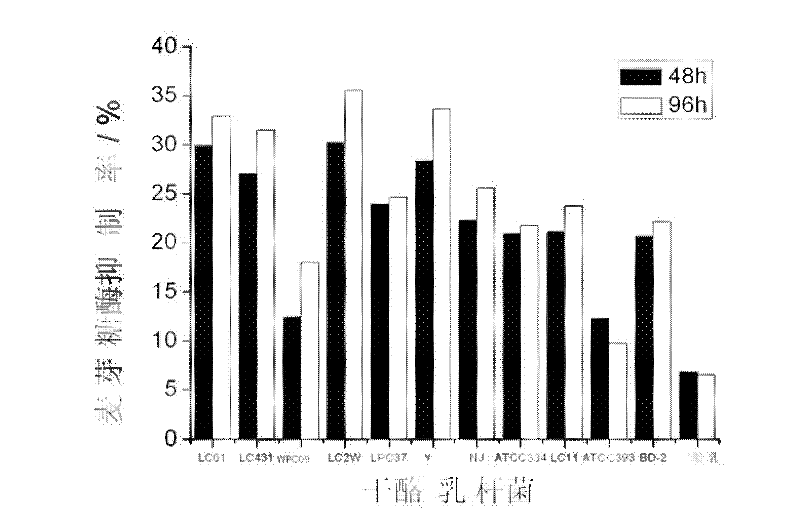

Image

Examples

preparation example Construction

[0031] Preparation of seeds 10% (w / w) skim milk, sterilized at 118°C for 15 minutes. Pick a small amount of bacterial lawn from a freshly cultivated MRS plate, transfer it to 1mL 10% (w / w) sterile skim milk, and culture it at 37°C for 24 hours, and then use 2% (v / v) inoculum In 10% (w / w) aseptic skimmed milk, further expand the culture to 10mL;

[0032]Preparation of fermented skim milk: The seeds were transferred to 10% (w / w) sterile skim milk (100 mL per 250 mL Erlenmeyer flask) at an inoculum size of 2% (v / v), and incubated at 37°C for 72 hours.

[0033] Preparation of test samples of fermented skim milk

[0034] After the fermentation was completed, the fermented sample was heated in a boiling water bath for 5 minutes, and after cooling to room temperature, it was centrifuged at 10,000 rpm at 4°C for 15 minutes, and the supernatant was taken. Adjust the pH value of the supernatant to 6.8 with 1mol / L NaOH, let it stand at room temperature for 30 minutes, then centrifuge a...

Embodiment 1

[0066] Embodiment 1 Lactobacillus casei LC2W does not add fermented milk

[0067] Fresh milk is homogenized at 30°C and 30Mpa, sterilized at 70°C for 30 minutes, then cooled to 25°C, inoculated with Lactobacillus casei LC2W with an inoculation amount of 3% (v / v), fermented at 37°C for 24 hours, cooled to 10°C, and bottled.

[0068] Index of fermented milk: Lactobacillus casei LC2W 2.3×10 9 CFU / mL, the inhibition rate of the fermentation product to maltase was 25.42%.

Embodiment 2

[0069] Embodiment 2 Lactobacillus casei LC2W lactic acid bacteria beverage

[0070]Whole fresh milk was preheated at 40°C, separated to obtain skimmed fresh milk, sterilized at 85°C for 10 minutes, cooled to 25°C; inoculated with Lactobacillus casei LC2W at an inoculum size of 3% (v / v), and fermented at 37°C for 72 hours. Dissolve sucralose, and sterilize at 95°C for 10 minutes, mix the fermentation broth and water at a ratio of 1:1.5, and add sucralose and monoglyceride fatty acid ester, so that the final concentrations of the two are 0.06‰ and 1.8‰ respectively , homogenized, cooled to 10°C, and aseptically filled. Lactic acid bacteria beverage index: Lactobacillus casei LC2W 4.5×10 7 CFU / mL, the fermentation product maltase inhibition rate was 28.56%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com