Process for cooling yellow wine fermented mash and equipment thereof

A technology for fermenting mash and yellow rice wine, applied in the field of winemaking technology, can solve the problems of high investment cost, unsuitable for rice wine fermentation, increase production cost, etc., and achieve the effects of saving investment, increasing evaporative cooling efficiency, and helping cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

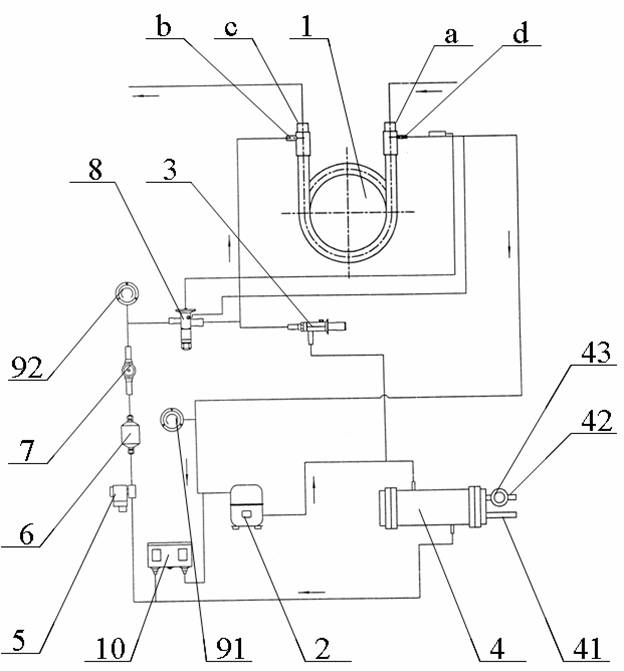

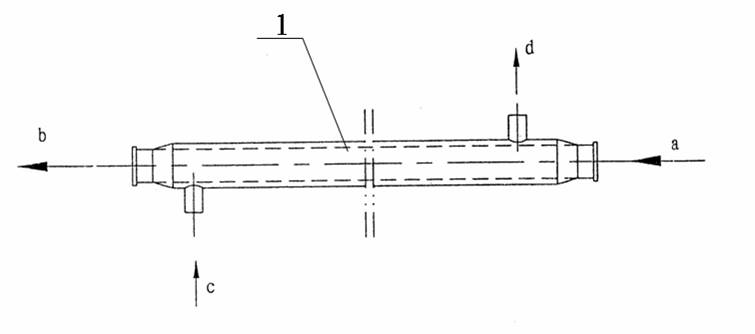

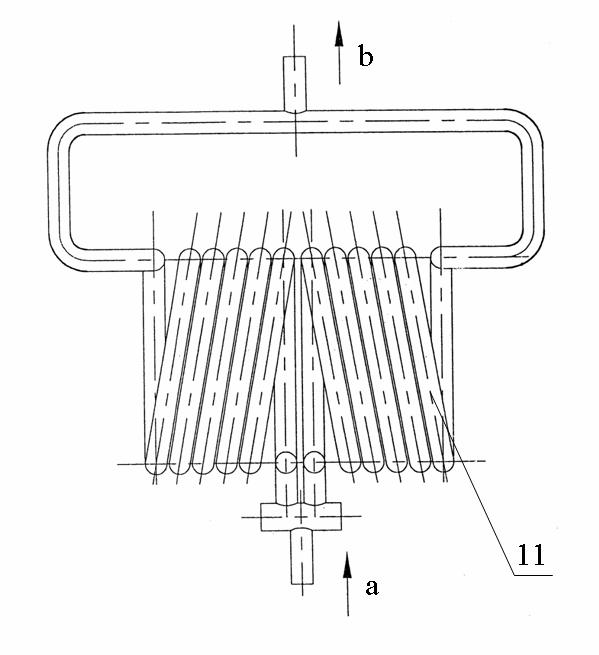

[0022] The present invention relates to a process for cooling yellow rice wine fermented mash, which comprises the following process steps: first heat the yellow rice wine fermented mash to 30-32°C, and then open the rake, so that the warmed yellow rice wine fermented mash passes through a coaxial heat exchanger 1, And the temperature of the coaxial heat exchanger 1 is controlled at about 7.5° C., and the warm rice wine fermented mash passes through the coaxial heat exchanger 1 to obtain cool rice wine fermented mash. Wherein, the coaxial heat exchanger 1 is provided with freon as a cooling medium, and direct use of freon for evaporative refrigeration can effectively increase the cooling capacity.

[0023] Please refer to the attached figure 1 to attach image 3 As shown, it is specifically a kind of rice wine fermentation mash cooling equipment, which consists of a coaxial heat exchanger 1, a refrigerant compressor 2, a hot gas bypass valve 3, a water condenser 4, a solenoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com