Surface-modified ZnO quantum dot and preparation method thereof

A surface modification, quantum dot technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of poor stability, narrow light emission wavelength adjustment range, low light emission intensity, etc., to achieve high stability and improve adjustability. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add 0.439g of zinc acetate dihydrate into 20mL of absolute ethanol under magnetic stirring, heat to 80°C, condense and reflux for 2 hours to obtain a 0.1mol / L zinc acetate ethanol solution;

[0037] The zinc acetate ethanol solution was pre-cooled to 0°C, then 0.293 g of silane coupling agent was added, and magnetically stirred for 60 min to obtain a zinc acetate ethanol solution stabilized by the silane coupling agent.

[0038] Add 0.0839g of lithium hydroxide monohydrate into 20mL of ethanol, and ultrasonically dissolve to obtain a lithium hydroxide ethanol solution with a concentration of 0.1mol / L;

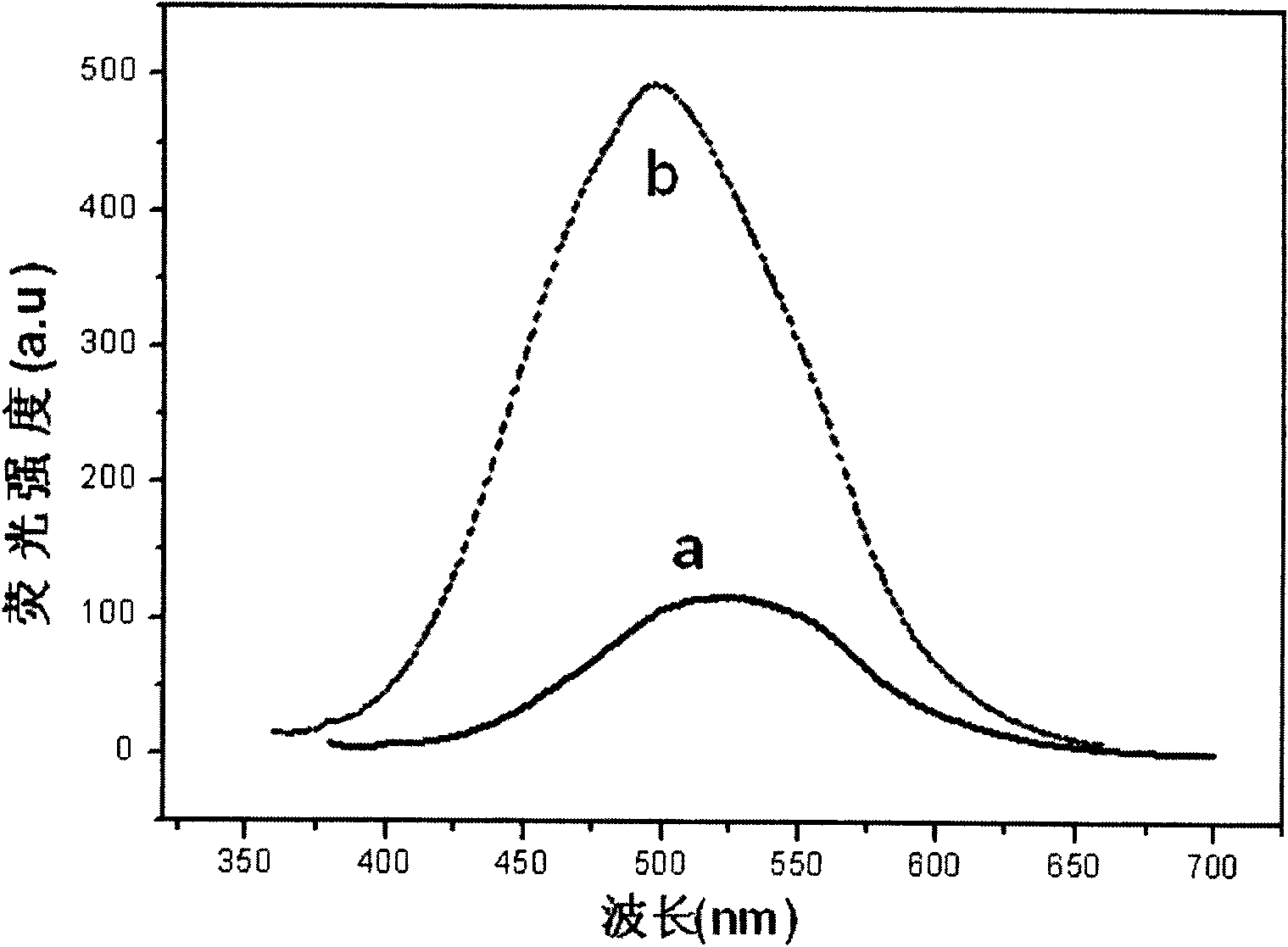

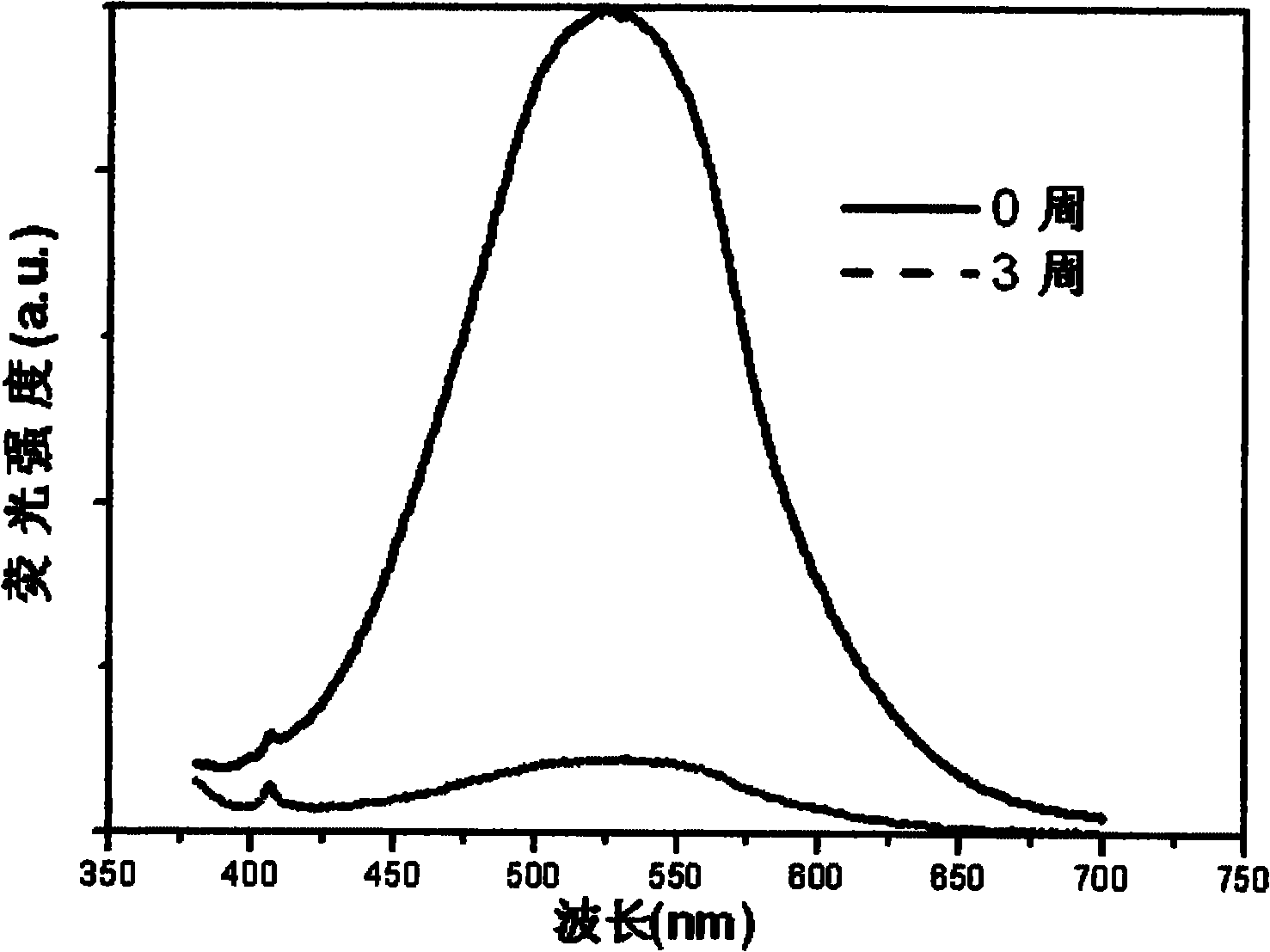

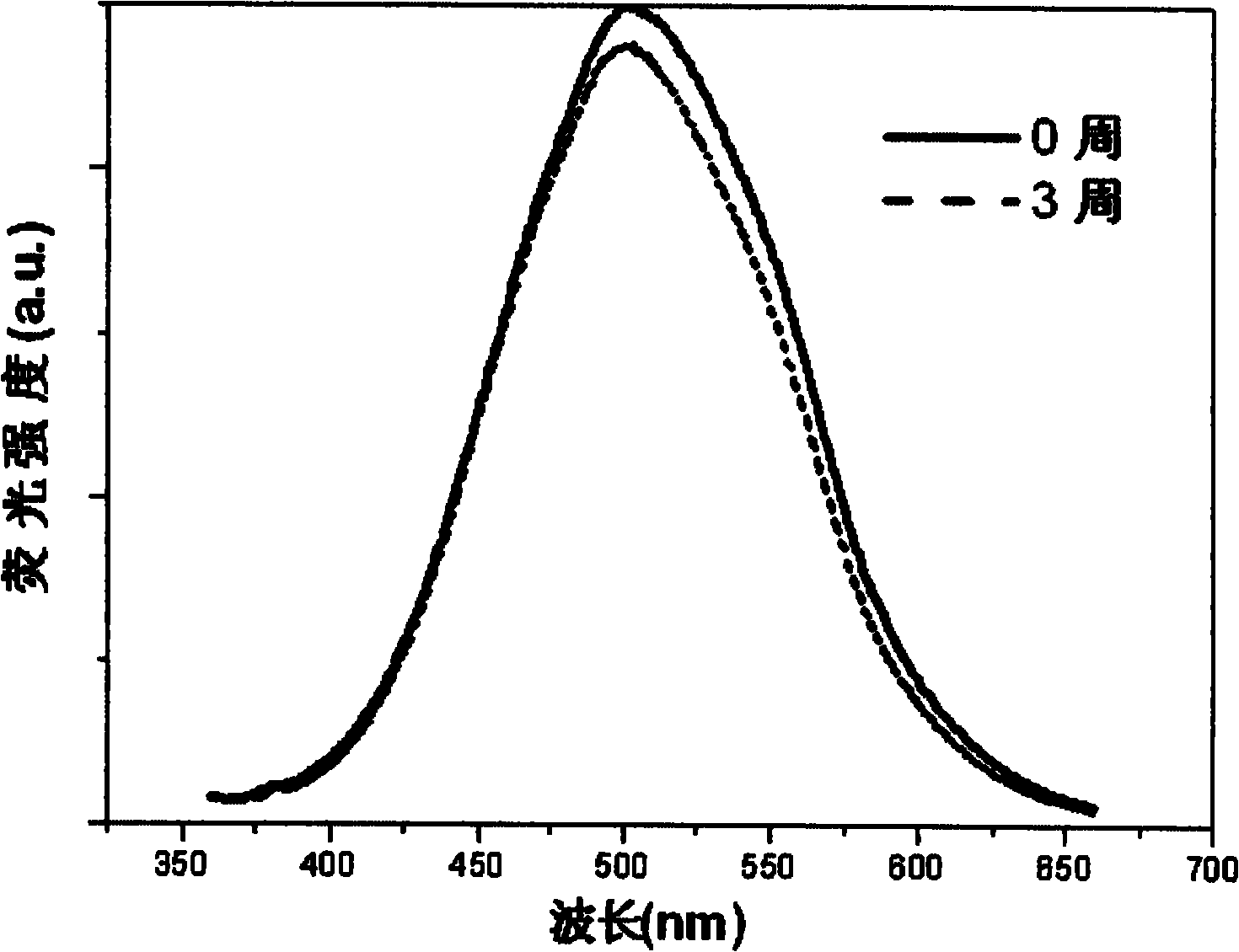

[0039] Lithium hydroxide ethanol solution was added to the zinc acetate ethanol solution stabilized by the silane coupling agent, and magnetically stirred for 30 minutes to obtain the colorless and transparent ZnO quantum dots surface-modified by the silane coupling agent in this example. The average particle diameter of the ZnO quantum dot is 3nm, and the position of th...

Embodiment 2

[0042] Add 0.439g of zinc acetate dihydrate into 20mL of absolute ethanol under magnetic stirring, heat to 80°C, condense and reflux for 5 hours to obtain a 0.1mol / L zinc acetate ethanol solution;

[0043] The zinc acetate ethanol solution was pre-cooled to 0°C, then 0.6 g of silane coupling agent was added, and magnetically stirred for 15 minutes to obtain a zinc acetate ethanol solution stabilized by the silane coupling agent.

[0044] Add 0.1175g of lithium hydroxide monohydrate into 20mL of ethanol, and ultrasonically dissolve to obtain a lithium hydroxide ethanol solution with a concentration of 0.14mol / L;

[0045] Lithium hydroxide ethanol solution was added to the zinc acetate ethanol solution stabilized by the silane coupling agent, and magnetically stirred for 30 minutes to obtain the colorless and transparent ZnO quantum dots surface-modified by the silane coupling agent in this example. The average particle size of the ZnO quantum dot is 2nm, and the position of the...

Embodiment 3

[0047] Add 0.439g of zinc acetate dihydrate into 20mL of absolute ethanol under magnetic stirring, heat to 80°C and reflux for 1 hour to obtain a 0.1mol / L zinc acetate ethanol solution;

[0048] The zinc acetate ethanol solution was pre-cooled to 0°C, then 1.75 g of silane coupling agent was added, and magnetically stirred for 30 min to obtain a zinc acetate ethanol solution stabilized by the silane coupling agent.

[0049] Add 0.2937g of lithium hydroxide monohydrate into 20mL of ethanol, and ultrasonically dissolve to obtain a lithium hydroxide ethanol solution with a concentration of 0.35mol / L;

[0050] Lithium hydroxide ethanol solution was added to the zinc acetate ethanol solution stabilized by the silane coupling agent, and magnetically stirred for 30 minutes to obtain the colorless and transparent ZnO quantum dots surface-modified by the silane coupling agent in this example. The average particle diameter of the ZnO quantum dot is 1nm, and the position of the fluoresce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com