Cover glass and method for producing same

A technology for a glass cover sheet and a manufacturing method, which is applied to glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve problems such as complicated processes, and achieve the effects of improving production efficiency, improving ion exchange performance, and excellent mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

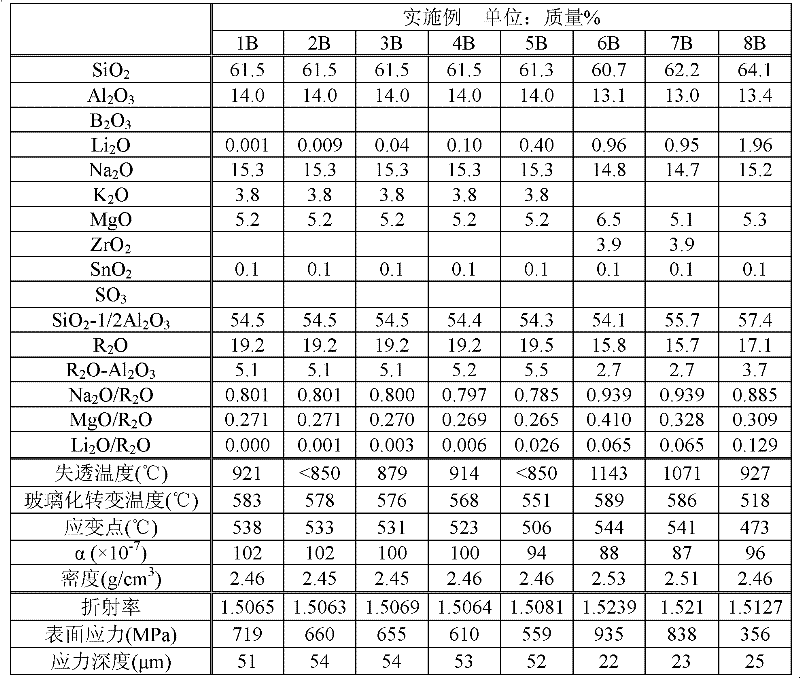

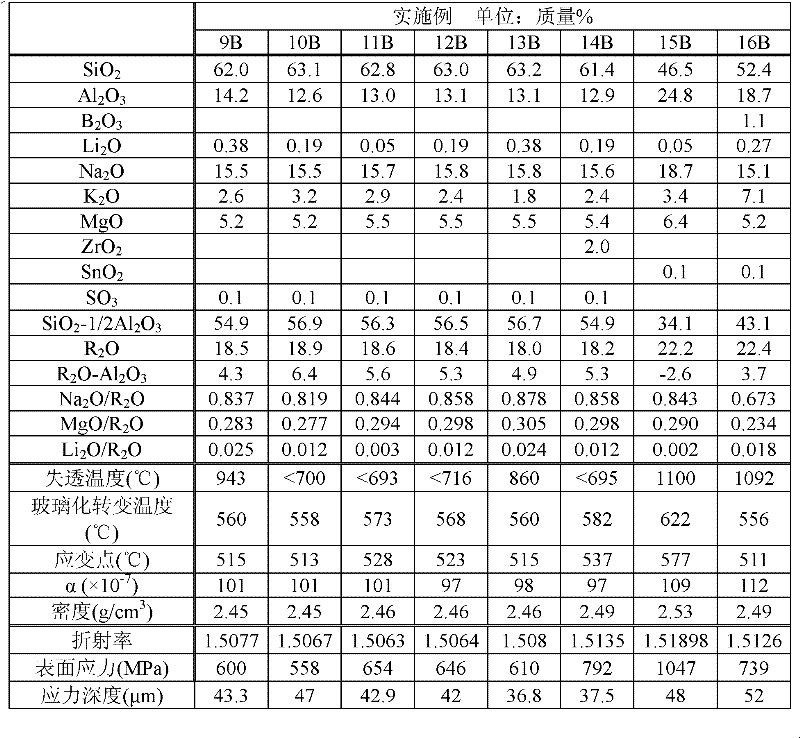

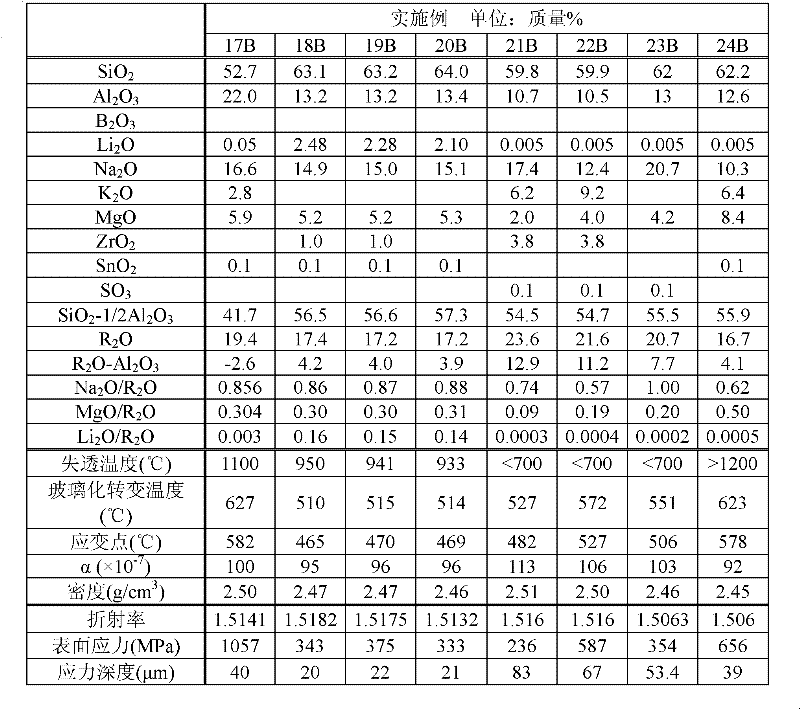

[0324] Hereinafter, examples of the cover glass of the present embodiment and its manufacturing method will be described in detail.

[0325] (manufacturing of glass substrates)

[0326] In order to form the glass compositions shown in Table 1 (Examples 1A to 42A) and Table 2 (Examples 1B to 24B) and Comparative Examples 1A, 2A, 1B to 4B, silica, which is a common glass raw material, Aluminum oxide, sodium carbonate, potassium carbonate, basic magnesium carbonate, lithium carbonate, calcium carbonate, zirconia, boria and / or clarifiers (such as tin oxide, sodium sulfate) to prepare glass raw materials (batch materials).

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive stress | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com